John it has been a while since you have posted some of your work. this is a nice looking old pipe once you finished it up. Good work.

The first thing I need to say is –

“Put the knife down and step away from the pipe!!”

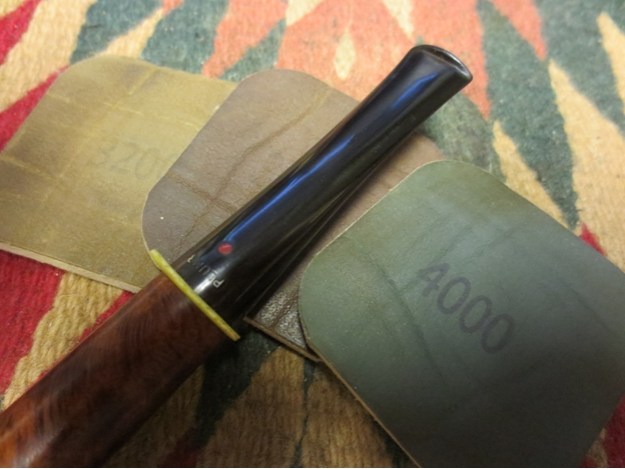

I got this on eBay recently and was dubious of the buy but got it cheap enough. It has a stem with the letters BC in a plastic / lexan insert in it. In looking up the BC it resembles the Butz – Choquin style. The fit is good and it has a 9mm filter inside. The nomenclature on the pipe is in good shape and says Peterson XL90s on the right and Shamrock filter on the left. The stem had a very rough texture to it, like it had been sand blasted. It wasn’t scratched as in sanding, just raised material that was very dull in color.

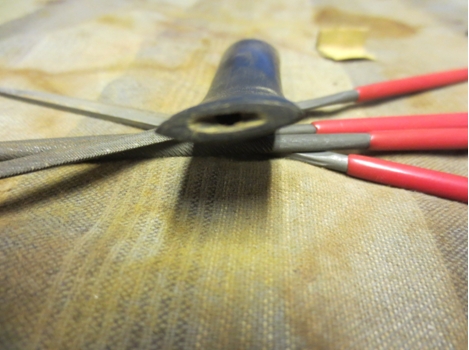

The reason for the first comment was that a prior owner had left knife marks in the cake. A reamer was a foreign…

View original post 453 more words