Blog by Steve Laug

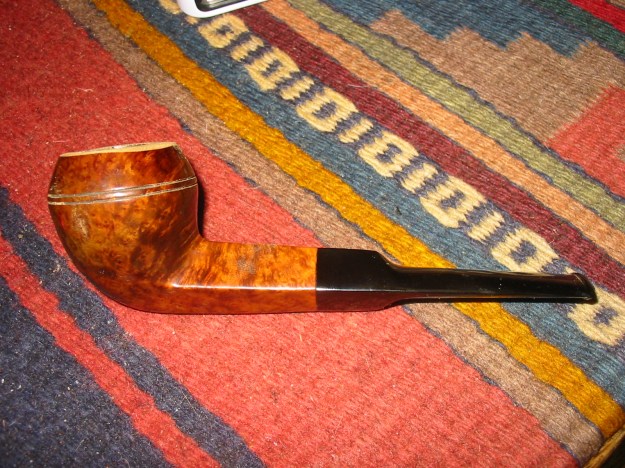

The next little pipe that I reworked for Vancouver Pipe Club donation of pipes is a nice lumberman. It is stamped on the left side of the shank Partner over De Luxe and on the right side it is stamped Fine Briar over 129. Further research has led me to information that this pipe was made by Savinelli. The shape number matches the number for a pipe shaped like this one. The finish was spotty with light and dark areas around the bowl and shank. The top of the rim had damage on the flat surface and burn marks all the way around the outer and inner edge of the bowl. The outer edge was rough to the touch. The grain was a nice combination of birdseye and cross grain. There were two repaired fills on the top of the shank. The stem had one tooth mark on the underside of the stem and there was tooth chatter on the top side of the stem.

The first photo below is a close up of the rim to show the damage to the surface of the rim and the inner and outer edges. The second photo below shows the burn marks around the outer edge of the bowl.

I topped the bowl using the method I have written about previously to remove the damage to the rim surface and edges. I used a folded piece of sandpaper to bevel the inner edge of the bowl and smooth out the damage and minimize it in the bowl.

I wiped the bowl down with acetone on cotton pads until I had removed the varnish coat and the stain as much as possible. It always makes matching the freshly topped rim with the rest of the pipe if the briar is as neutral as possible.

The tooth mark on the bottom of the stem and the tooth chatter on the top of the stem needed to be sanded. The first photo below shows the damage on the bottom of the stem next to the button. I sanded both surfaces with 220 grit sandpaper and then with a medium grit sanding sponge until the tooth chatter was gone and the tooth mark was minimized.

I continued to sand the stem with my usual array of micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12,000 grit pads.

I rubbed the stem down with Obsidian Oil and then buffed the stem with White Diamond. I took the pipe back to the work table and restained the bowl and shank with MinWax Medium Walnut stain to bring life back to the briar. I stained the light areas on the rim and at the shank stem junction multiple times until they matched the rest of the pipe.

I buffed the pipe and stem with White Diamond a final time to remove any remaining scratch marks and then gave the pipe multiple coats of carnauba wax to protect and give it a shine. The finished pipe is shown below. It joins the others I have refurbished for the Vancouver Pipe Club box of donated pipes.