By Steve Laug

We met up at a local eatery and had a great breakfast together with our aunt. We took her to her residence afterwards and visited with her for most of the morning. Together we headed to Old Town Bellingham to begin our pipe hunt. We visited three of my favourite antique malls and worked out way through the aisles of wares for sale. Jeff and I tend to divide and conquer, each walking through the aisles of the shop looking for pipes. The rest of the family moves through looking for their own treasures. In the first shop there was a rack and in it were two pipes. The first was a Sasieni Royal Stuart Billiard and the second was a Sasieni Mayfair Apple. Both were great and were added to the hunt bag. Here is the link to the blog on the hunt and a photo of the pipes we added (https://rebornpipes.com/tag/bellingham-pipe-hunt/). Both were dirty but both contained the Sasieni Magic – classic shapes and nice briar.  The next pipe on the work table is the second Sasieni a Mayfair Apple which is the upper pipe in the photo below. It is stamped on the left side of the shank and has a rugby ball stamp Made in England next to the shank/bowl junction. That is followed by Sasieni [over] Mayfair. On the right side it has the shape number 52N next to the bowl/shank junction followed by London Made stamped mid shank. The stem has an M logo on the topside. The bowl had a thick cake and a thick lava overflow on the rim. It was hard to estimate the condition of the rim top with the cake and lava coat but I was hoping it had been protected from damage. It appeared that the outer edge was in decent condition. The finish was a classic Sasieni smooth. The finish was dusty and tired but had some nice grain under the grime and the finish appeared to be in good condition. There were a few nicks in the surface on the left side of the bowl. A lot would be revealed once I had cleaned it. The stem was dirty, oxidized, calcified and had tooth chatter and tooth marks near the button on both sides. I took photos of the pipe before I stated my cleanup work.

The next pipe on the work table is the second Sasieni a Mayfair Apple which is the upper pipe in the photo below. It is stamped on the left side of the shank and has a rugby ball stamp Made in England next to the shank/bowl junction. That is followed by Sasieni [over] Mayfair. On the right side it has the shape number 52N next to the bowl/shank junction followed by London Made stamped mid shank. The stem has an M logo on the topside. The bowl had a thick cake and a thick lava overflow on the rim. It was hard to estimate the condition of the rim top with the cake and lava coat but I was hoping it had been protected from damage. It appeared that the outer edge was in decent condition. The finish was a classic Sasieni smooth. The finish was dusty and tired but had some nice grain under the grime and the finish appeared to be in good condition. There were a few nicks in the surface on the left side of the bowl. A lot would be revealed once I had cleaned it. The stem was dirty, oxidized, calcified and had tooth chatter and tooth marks near the button on both sides. I took photos of the pipe before I stated my cleanup work.

I took a close-up photo of the bowl and rim top to show its condition. The bowl had a thick cake in it and an overflow of lava on the top of the rim. The previous pipeman had left a mess for me to clean up. The stem was also is a mess. There was some tooth marks and dents on the top and underside ahead of the button. There was a thick coat of calcification and oxidation on the stem. M logo stamp on top of the stem was clear and readable.

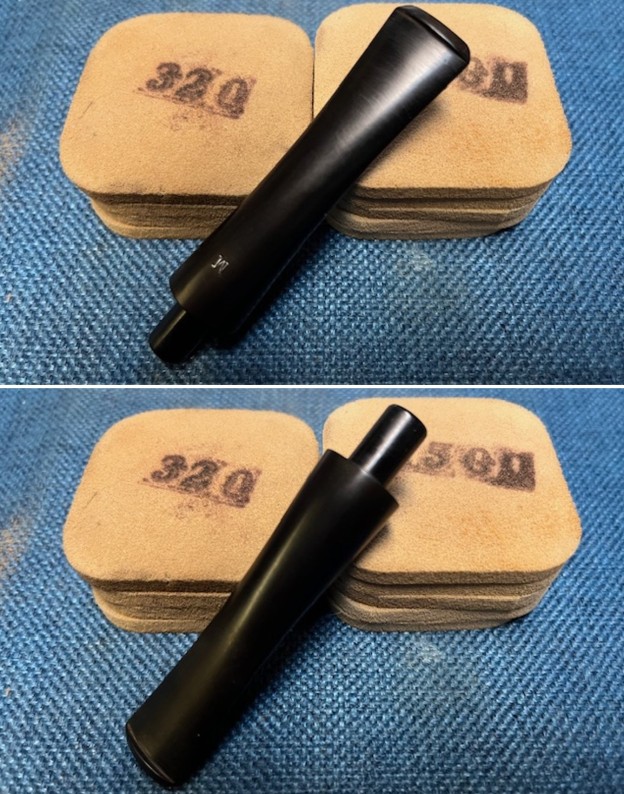

I took a close-up photo of the bowl and rim top to show its condition. The bowl had a thick cake in it and an overflow of lava on the top of the rim. The previous pipeman had left a mess for me to clean up. The stem was also is a mess. There was some tooth marks and dents on the top and underside ahead of the button. There was a thick coat of calcification and oxidation on the stem. M logo stamp on top of the stem was clear and readable. I took photos of the stamping on the right and left side of the shank. It is clear and readable as noted above. I removed the stem from the shank and took a photo of the parts. It is a beautiful pipe. The stinger apparatus is missing and the airway in the tenon is the same as the Royal Stuart that I worked on (https://rebornpipes.com/2024/06/16/cleaning-up-another-bellingham-pipe-hunt-find-a-sasieni-royal-stuart-55-billiard/).

I took photos of the stamping on the right and left side of the shank. It is clear and readable as noted above. I removed the stem from the shank and took a photo of the parts. It is a beautiful pipe. The stinger apparatus is missing and the airway in the tenon is the same as the Royal Stuart that I worked on (https://rebornpipes.com/2024/06/16/cleaning-up-another-bellingham-pipe-hunt-find-a-sasieni-royal-stuart-55-billiard/).

As is my usual practice I turned to Pipephil (http://www.pipephil.eu/logos/en/logo-sasieni2.html) to look for any information on the Mayfair line. It was not listed in the original Sasieni list but it did come up in the Sasieni Seconds list. It was listed there and I did a screen capture of the section and have included it below. The logo on the pipe stem I was working on is stamped like the third one below. The shank stamp was like the one in the third photo below.

As is my usual practice I turned to Pipephil (http://www.pipephil.eu/logos/en/logo-sasieni2.html) to look for any information on the Mayfair line. It was not listed in the original Sasieni list but it did come up in the Sasieni Seconds list. It was listed there and I did a screen capture of the section and have included it below. The logo on the pipe stem I was working on is stamped like the third one below. The shank stamp was like the one in the third photo below.  From that information I knew that I was dealing with a Family Era Sasieni with the white M logo that was used on these older ones. That placed the date before 1979 when the company was sold.

From that information I knew that I was dealing with a Family Era Sasieni with the white M logo that was used on these older ones. That placed the date before 1979 when the company was sold.

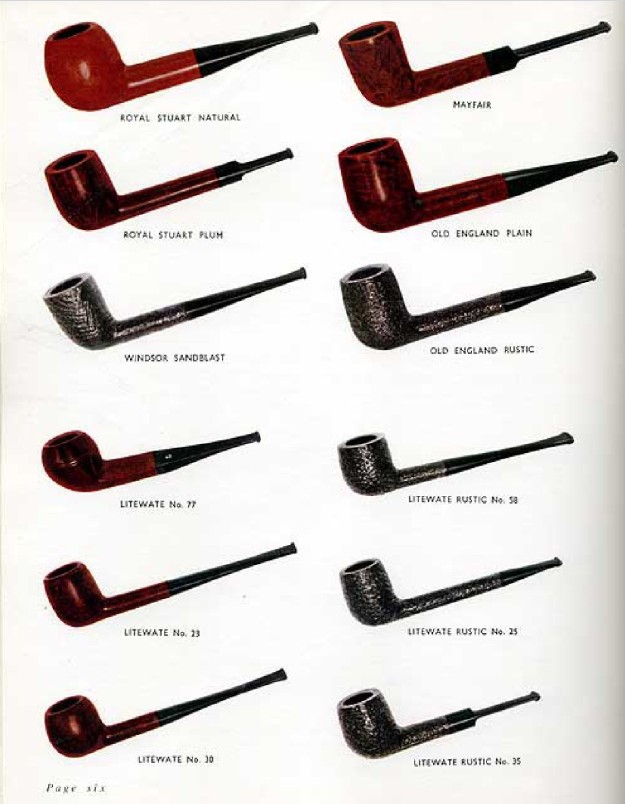

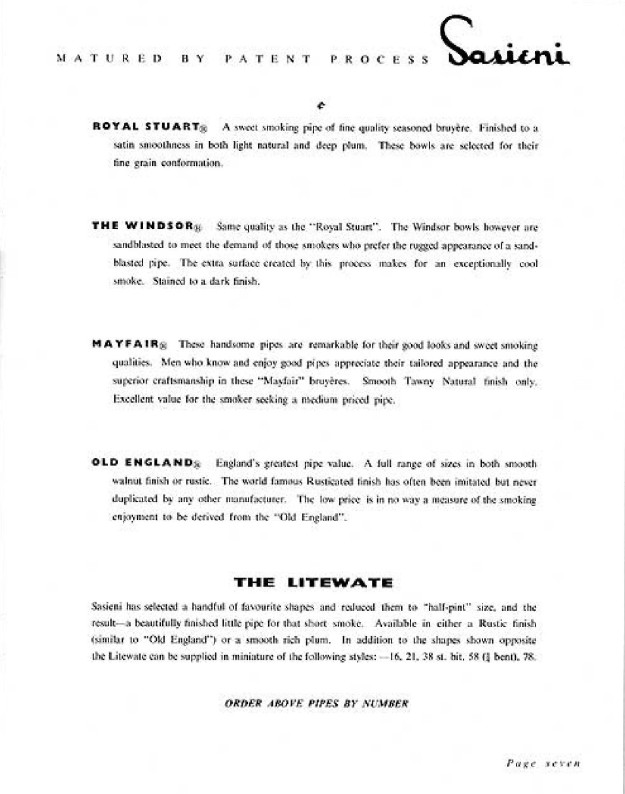

From there I turned to Pipedia and read through the history of the brand. It confirmed the date of manufacture as pre-1979. At the bottom of the Pipedia article there was a 1965 catalogue. I have included the link to the catalogue (https://pipedia.org/images/1/1b/Sasieni_1965.pdf). Page six of the catalogue had a listing of the Sasieni lines and on the top right column the Mayfair was shown.

Page seven below gives a great description of the Mayfair line. It reads: Mayfair – these handsome pipes are remarkable for their good looks and sweet smoking qualities. Men who know and enjoy good pipes appreciate their tailored appearance and the superior craftsmanship in these “Mayfair” bruyeres. Smooth Tawny Natural finish only. Excellent value for the smoker seeking a medium priced pipe.

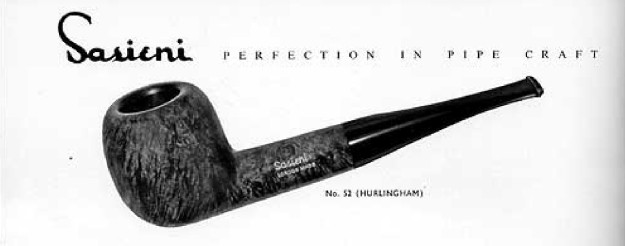

Now I knew that is was not a second at all at this point in time. It was rather a well made pipe selected for its tailored appearance and superior craftsmanship on a medium priced pipe. That also pushed the date back to at 1965. The catalogue also had a shape photo that matched the numbers on the pipe I am working on. The shape 52 was known as a Hurlingham and was used in quite a few of the Sasieni lines for that large Apple. I have included a screen capture of the shape photo in the catalogue.

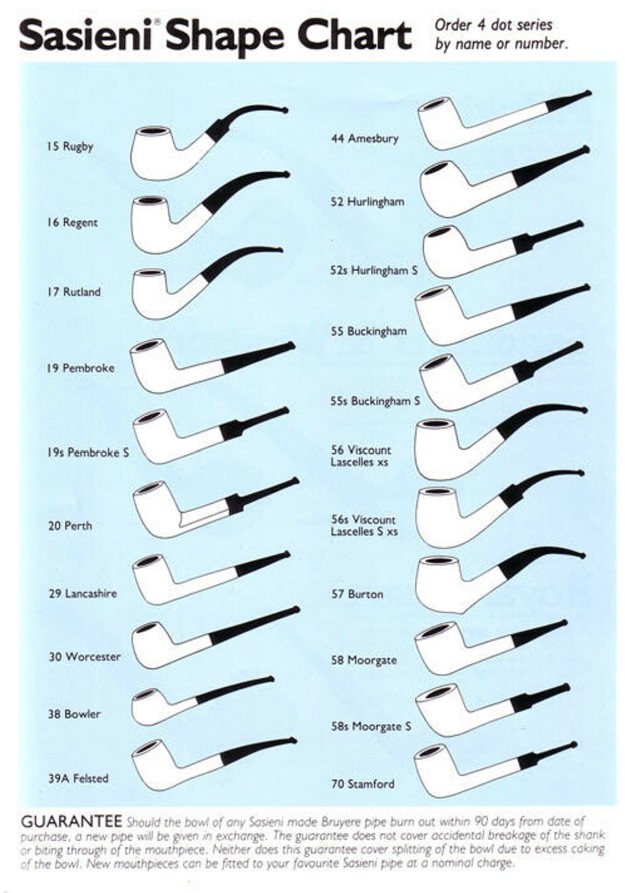

Now I knew that is was not a second at all at this point in time. It was rather a well made pipe selected for its tailored appearance and superior craftsmanship on a medium priced pipe. That also pushed the date back to at 1965. The catalogue also had a shape photo that matched the numbers on the pipe I am working on. The shape 52 was known as a Hurlingham and was used in quite a few of the Sasieni lines for that large Apple. I have included a screen capture of the shape photo in the catalogue. There was also a shape chart on Pipedia and I have saved the page that included the shape of the 52N (Hurlingham) (https://pipedia.org/wiki/File:Sasnieni_Shapes.jpg).

There was also a shape chart on Pipedia and I have saved the page that included the shape of the 52N (Hurlingham) (https://pipedia.org/wiki/File:Sasnieni_Shapes.jpg). Now I knew what I was working on. It was a pre-1965 Apple in the Hurlingham shape in an early version of the Mayfair and in Smooth Tawny Natural finish that had taken on some colour through smoking. Now it was time to start my work on it. I reamed the pipe with a PipNet pipe reamer using the second and the third cutting head to take the cake back to bare briar. I cleaned up the remnants of the cake with a Savinelli Fitsall Pipe Knife. I finished the bowl internals by sanding the bowl walls with 220 grit sandpaper wrapped around a piece of dowel. The bowl walls looked very good with no checking or cracking to the walls.

Now I knew what I was working on. It was a pre-1965 Apple in the Hurlingham shape in an early version of the Mayfair and in Smooth Tawny Natural finish that had taken on some colour through smoking. Now it was time to start my work on it. I reamed the pipe with a PipNet pipe reamer using the second and the third cutting head to take the cake back to bare briar. I cleaned up the remnants of the cake with a Savinelli Fitsall Pipe Knife. I finished the bowl internals by sanding the bowl walls with 220 grit sandpaper wrapped around a piece of dowel. The bowl walls looked very good with no checking or cracking to the walls.

I scraped the heavy lava on the rim top with the edge of the Savinelli Fitsall Pipe Knife. I was able to remove the majority of the build up. The rest would come up after I scrubbed the bowl.

I scraped the heavy lava on the rim top with the edge of the Savinelli Fitsall Pipe Knife. I was able to remove the majority of the build up. The rest would come up after I scrubbed the bowl. I decided to scrub the bowl with Mark Hoover’s Before & After Briar Cleaner. He had sent me a sample to try out so this was the first pipe to try it out on. I shook the jar to make sure it was well mixed. I applied it to the surface of the briar bowl and the filthy rim top with my finger tips. I scrubbed it with a tooth brush and wiped it off with a cotton pad to remove the grime and the residual product left on the briar. It looked much better once I had cleaned it. I rinsed it off with warm water and dried the briar with a cotton cloth.

I decided to scrub the bowl with Mark Hoover’s Before & After Briar Cleaner. He had sent me a sample to try out so this was the first pipe to try it out on. I shook the jar to make sure it was well mixed. I applied it to the surface of the briar bowl and the filthy rim top with my finger tips. I scrubbed it with a tooth brush and wiped it off with a cotton pad to remove the grime and the residual product left on the briar. It looked much better once I had cleaned it. I rinsed it off with warm water and dried the briar with a cotton cloth.

There were still some flecks of paint and debris on the briar and the rim top still had some lava that I needed to remove. I wiped the bowl with a cotton pad and acetone and cleaned off the remainder of the debris and the briar looked very good.

There were still some flecks of paint and debris on the briar and the rim top still had some lava that I needed to remove. I wiped the bowl with a cotton pad and acetone and cleaned off the remainder of the debris and the briar looked very good.

With the externals cleaned it was now time to work on the internals of the mortise, shank and airway in the stem. I scraped the walls of the shank with a dental spatula and took a lot of tars and oils out with the spatula. From there I cleaned up the debris with pipe cleaners, cotton swabs and isopropyl alcohol until it was clean and the smell was gone. I cleaned the airway in the stem with alcohol, cotton swabs and pipe cleaners. I used both bristle and fluffy pipe cleaners to clean out the oils and tars. I scoured out the open tenon with a cotton swab. It came out looking much better.

With the externals cleaned it was now time to work on the internals of the mortise, shank and airway in the stem. I scraped the walls of the shank with a dental spatula and took a lot of tars and oils out with the spatula. From there I cleaned up the debris with pipe cleaners, cotton swabs and isopropyl alcohol until it was clean and the smell was gone. I cleaned the airway in the stem with alcohol, cotton swabs and pipe cleaners. I used both bristle and fluffy pipe cleaners to clean out the oils and tars. I scoured out the open tenon with a cotton swab. It came out looking much better.

I set the stem aside and went back to working on the bowl. I sanded the briar with 320-3500 grit sanding pads. I wiped the briar down after each sanding pad with a damp cloth to remove the debris that was left behind. By the time I finished the last pad the briar was very smooth and clean to the touch.

I set the stem aside and went back to working on the bowl. I sanded the briar with 320-3500 grit sanding pads. I wiped the briar down after each sanding pad with a damp cloth to remove the debris that was left behind. By the time I finished the last pad the briar was very smooth and clean to the touch.

I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped it down with a damp cloth after each sanding pad. The bowl began to really shine with the polishing.

I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped it down with a damp cloth after each sanding pad. The bowl began to really shine with the polishing.

I worked some Before & After Restoration Balm into the finish of the briar with my finger tips. The product works well to clean, enliven and protect the briar and really brings it back to life. I have been using it for quite a few years now and really like the way it makes the briar come alive and makes the grain pop.

I worked some Before & After Restoration Balm into the finish of the briar with my finger tips. The product works well to clean, enliven and protect the briar and really brings it back to life. I have been using it for quite a few years now and really like the way it makes the briar come alive and makes the grain pop.

I set aside the bowl and turned my attention to the stem. I “painted” the tooth marks on the surface of the stem and was able to lift them all. I blended the remaining marks into the surface with a folded piece of 220 grit sandpaper.

I set aside the bowl and turned my attention to the stem. I “painted” the tooth marks on the surface of the stem and was able to lift them all. I blended the remaining marks into the surface with a folded piece of 220 grit sandpaper.

I worked on the oxidation on the stem with Soft Scrub and cotton pads. I find that the product really cut through the deep oxidation and removes it well. I worked on both side of the stem and was pleased that it did no harm the “M” stamp on the topside of the stem.

I worked on the oxidation on the stem with Soft Scrub and cotton pads. I find that the product really cut through the deep oxidation and removes it well. I worked on both side of the stem and was pleased that it did no harm the “M” stamp on the topside of the stem. I sanded the stem with 320-3500 grit sanding pads to blend in the scratch marks from the 220 grit sandpaper and to remove the residual oxidation that still remained. I wiped it down after each sanding pad with a damp cloth. By the final 3500 grit sanding pad the stem had a more normal shine and the oxidation, tooth marks and chatter were gone.

I sanded the stem with 320-3500 grit sanding pads to blend in the scratch marks from the 220 grit sandpaper and to remove the residual oxidation that still remained. I wiped it down after each sanding pad with a damp cloth. By the final 3500 grit sanding pad the stem had a more normal shine and the oxidation, tooth marks and chatter were gone. I decided to touch up the M stamp on the top of the stem at this point. I used an acrylic white fingernail polish and it dries hard and matches very well. I applied it with the brush in the cap and worked it into the stamp with a tooth pick. Once it was cured I lightly sanded it off with a 1500 grit micromesh sanding pad.

I decided to touch up the M stamp on the top of the stem at this point. I used an acrylic white fingernail polish and it dries hard and matches very well. I applied it with the brush in the cap and worked it into the stamp with a tooth pick. Once it was cured I lightly sanded it off with a 1500 grit micromesh sanding pad. I polished the vulcanite with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

I polished the vulcanite with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

This Sasieni Mayfair 52N Apple with a vulcanite taper stem has a beautiful, unique Natural Sasieni finish that has some great grain standing out. The polished vulcanite taper stem adds to the mix. I put the stem back on the bowl and buffed the pipe with Blue Diamond on the buffing wheel being careful to not buff the stamping. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing it with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Made in England Sasieni Mayfair 52N Apple is quite nice and feels great in the hand. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.76 ounces/50 grams. Thanks for walking through the restoration with me as I worked over another beautiful pipe. This one will be going on the rebornpipes store in the English Pipe Makers Section. Thanks for your time.

This Sasieni Mayfair 52N Apple with a vulcanite taper stem has a beautiful, unique Natural Sasieni finish that has some great grain standing out. The polished vulcanite taper stem adds to the mix. I put the stem back on the bowl and buffed the pipe with Blue Diamond on the buffing wheel being careful to not buff the stamping. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing it with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Made in England Sasieni Mayfair 52N Apple is quite nice and feels great in the hand. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.76 ounces/50 grams. Thanks for walking through the restoration with me as I worked over another beautiful pipe. This one will be going on the rebornpipes store in the English Pipe Makers Section. Thanks for your time.