by Steve Laug

While I was travelling in the US I received an email from Dave regarding restoring a meerschaum pipe that he had. I quote from the initial email below:

Hello, I have a meerschaum pipe that needs some TLC. I was wondering if you do restorations for pipes that you send back to the owner. I’m sure it somewhat depends on the condition. I’d be happy to send you some pictures if you do that kind of work and would be willing to give me a ballpark estimate. Thank you! Dave

I wrote back to Dave and asked him to send photos of the pipe. Once I received them I looked them over and answered Dave’s questions in the initial email. I gave him my malling address and last evening I received his pipe. I have included the photos of the pipe that he sent me below.

This morning I started working on Dave’s pipe. I brought the Baki to the work table. It came in its own hard-shell case that is covered with a red leather and with a soft gold velour like fabric on the inside of the case. There are no logos or marks in the case itself. Dave had taped a paper label on the case that reads FBK – C071. Next to the clasp on the front edge it reads Made in Turkey.

This morning I started working on Dave’s pipe. I brought the Baki to the work table. It came in its own hard-shell case that is covered with a red leather and with a soft gold velour like fabric on the inside of the case. There are no logos or marks in the case itself. Dave had taped a paper label on the case that reads FBK – C071. Next to the clasp on the front edge it reads Made in Turkey.

The pipe is dirty on the smooth finish with grime on the bowl sides. It does have a great looking developing patina that is darker on the shank than the bowl but the bowl is getting darker. The rim top has a coat of lava on the top and edges. The bowl has a thick cake on the walls overflowing onto the rim top. The original Cumberland saddle stem is dirty and oxidized. It bore the F. Baki stamp on the left side of the saddle. The threaded mortise was loose in the shank and came out when I turned the stem loose. The push tenon was quite clean and the fit was fairly snug in the threaded mortise. I took photos of the pipe when I removed it from the case to show what it looked like before I started working on it.

The pipe is dirty on the smooth finish with grime on the bowl sides. It does have a great looking developing patina that is darker on the shank than the bowl but the bowl is getting darker. The rim top has a coat of lava on the top and edges. The bowl has a thick cake on the walls overflowing onto the rim top. The original Cumberland saddle stem is dirty and oxidized. It bore the F. Baki stamp on the left side of the saddle. The threaded mortise was loose in the shank and came out when I turned the stem loose. The push tenon was quite clean and the fit was fairly snug in the threaded mortise. I took photos of the pipe when I removed it from the case to show what it looked like before I started working on it.

I took photos of the bowl and rim top to show the thickness of the cake and the lava coat on the rim top. There was some tobacco debris in the bottom of the bowl. The stem photos show the condition of the saddle stem ahead of the button.

I took photos of the bowl and rim top to show the thickness of the cake and the lava coat on the rim top. There was some tobacco debris in the bottom of the bowl. The stem photos show the condition of the saddle stem ahead of the button.  The stamping on the side of the saddle stem is clear and readable as noted above. I took a photo of the pipe with the stem removed to give a sense of the proportions of the pipe. It is a real beauty.

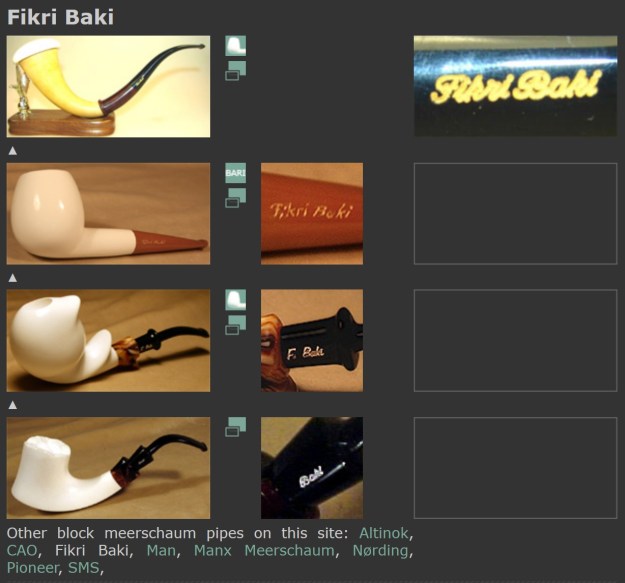

The stamping on the side of the saddle stem is clear and readable as noted above. I took a photo of the pipe with the stem removed to give a sense of the proportions of the pipe. It is a real beauty. Before I started working on the pipe I did a bit of research on the brand to learn as much as I could about it (http://www.pipephil.eu/logos/en/logo-f2.html#fikribaki). I did a screenshot of the pertinent information and have included it below.

Before I started working on the pipe I did a bit of research on the brand to learn as much as I could about it (http://www.pipephil.eu/logos/en/logo-f2.html#fikribaki). I did a screenshot of the pertinent information and have included it below. I turned next to Pipedia (https://pipedia.org/wiki/Fikri_Baki) and found a short quote from Pipes, Artisans and Trademarks, by Jose Manuel Lopés’

I turned next to Pipedia (https://pipedia.org/wiki/Fikri_Baki) and found a short quote from Pipes, Artisans and Trademarks, by Jose Manuel Lopés’

Fikri Baki is a young Turkish meerschaum pipe maker, who trained in Europe with a well-known artisan. He produces models inspired by contemporary Danish aesthetics, with handmade stems. For many years, Baki’s pipes were distributed exclusively by Deniz Ural. As of 2019, he is distributed by the Chinese-based TuWun Meerschaum store which is sold through AliExpress.

His stamp is his signature done on the side of the stem and is either F. Baki or on some newer pipes, Fikri Baki.

I turned also to the Meerschaum Market site (https://www.meerschaummarket.com/master-carvers/f-baki/) where I found a little more information on the maker. I quote: F. Baki

Fikri Baki Cetekinkaya is a well-known meerschaum pipe carver who lives in Eskisehir, Turkey. He was born in to meerschaum, he is from Sepetci, new name Beyazaltin village. Village’s new name means “White Gold” in English.

He started carving meerschaum pipes in 1969 as an apprentice. He had been trained by the top master carvers in 1970s. He worked on figural pipes for many years as all meerschaum pipe carvers. European pipe carvers inspired him and he moved away from sculpture carving to classic shapes, his own styles and freehands. His passion to meerschaum pipe carving took him to the most preferred carvers. He is the first master carver who worked with bamboo in Eskisehir. F. Baki is already retired…

I turned to work on the pipe itself. I reamed the bowl with a PipNet pipe reamer using the cutting heads 2 and 3. I finished the reaming with a Savinelli Fitsall Pipe Knife. I sanded the walls of the bowl with 220 grit sandpaper wrapped around a piece of dowel.

I cleaned out the inside of the shank and the airway in the stem with alcohol, cotton swabs and both bristle and regular pipe cleaners.

I cleaned out the inside of the shank and the airway in the stem with alcohol, cotton swabs and both bristle and regular pipe cleaners. I scrubbed the bowl and shank with a tooth brush and some undiluted Murphy’s Oil Soap. I rinsed it off with warm water to remove the dust and soap from the finish. I dried it off with a soft cloth and it looked much better.

I scrubbed the bowl and shank with a tooth brush and some undiluted Murphy’s Oil Soap. I rinsed it off with warm water to remove the dust and soap from the finish. I dried it off with a soft cloth and it looked much better.

I examined the bowl after it was clean and found a small crack on the underside of the shank. It was a small hairline crack that explained why Dave had noted in his email to me that the stem was loose. It also explained why the nylon threaded mortise in the shank was also loose. I gave it a think line of all-purpose glue and then coated the inside of the thin brass band with the glue as well. I pressed it on the shank end and wiped off the excess glue.

I examined the bowl after it was clean and found a small crack on the underside of the shank. It was a small hairline crack that explained why Dave had noted in his email to me that the stem was loose. It also explained why the nylon threaded mortise in the shank was also loose. I gave it a think line of all-purpose glue and then coated the inside of the thin brass band with the glue as well. I pressed it on the shank end and wiped off the excess glue.

I worked over the rim top lava build up and the scratches on the walls of the bowl and shank with 320-3500 grit 2×2 inch sanding pads. I wiped the bowl down with a damp cloth after each sanding pad. The crowned smooth rim top looks good.

I worked over the rim top lava build up and the scratches on the walls of the bowl and shank with 320-3500 grit 2×2 inch sanding pads. I wiped the bowl down with a damp cloth after each sanding pad. The crowned smooth rim top looks good.

I polished the meerschaum with 1500-12000 grit sanding pads. I wiped the bowl down after each sanding pad with a damp cloth to remove the sanding debris. By the time I finished the bowl took on a rich and clean shine.

I polished the meerschaum with 1500-12000 grit sanding pads. I wiped the bowl down after each sanding pad with a damp cloth to remove the sanding debris. By the time I finished the bowl took on a rich and clean shine.

I rubbed the meerschaum down with some Clapham’s Beeswax/Carnauba Wax. I let it sit for a short time then hand buffed it with a soft cloth to raise the shine on the meer.

I rubbed the meerschaum down with some Clapham’s Beeswax/Carnauba Wax. I let it sit for a short time then hand buffed it with a soft cloth to raise the shine on the meer.

I used a folded piece of 220 grit sandpaper to sand out the tooth marks and chatter on both sides ahead of the button. It did not take too long to work out the tooth marks and chatter in the surface of the Cumberland.

I used a folded piece of 220 grit sandpaper to sand out the tooth marks and chatter on both sides ahead of the button. It did not take too long to work out the tooth marks and chatter in the surface of the Cumberland. I touched up the stamping on the left side of the saddle stem with white acrylic fingernail polish. I worked it into the stamping with a tooth pick. I set it aside to dry and then I sanded it off with a worn 1500 grit micromesh sanding pad.

I touched up the stamping on the left side of the saddle stem with white acrylic fingernail polish. I worked it into the stamping with a tooth pick. I set it aside to dry and then I sanded it off with a worn 1500 grit micromesh sanding pad. I set the bowl aside and turned my attention to the stem. I sanded the stem with 320-3500 grit 2×2 inch pads. I wiped the stem down with an Obsidian Oil cloth after each sanding pad. The rich look of the Cumberland began to take on a shine.

I set the bowl aside and turned my attention to the stem. I sanded the stem with 320-3500 grit 2×2 inch pads. I wiped the stem down with an Obsidian Oil cloth after each sanding pad. The rich look of the Cumberland began to take on a shine. I polished the vulcanite with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

I polished the vulcanite with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

I the polished stem and the Meerschaum Bent Egg bowl with Blue Diamond to polish out the remaining small scratches and raise the shine. I gave the Cumberland stem several coats of carnauba wax and the bowl several coats of Clapham’s Beeswax/Canuaba Wax then buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. This turned out to be a beautiful Fikri Baki Meerschaum Danish Egg. The finished pipe is shown in the photos below. The dimensions are Length: 6 inches, Height: 2 ¼ inches, Outside diameter of the bowl: 1 ½ inches long by 1 ¼ inches wide, Chamber diameter: 7/8 of an inch. The weight of the pipe is 1.94 ounces/53 grams. Thanks for walking through the restoration with me as I worked this beautiful F. Baki Meerschaum Danish Egg. I will be sending it back very soon to the pipeman who asked me to restore it. Thanks for looking.

I the polished stem and the Meerschaum Bent Egg bowl with Blue Diamond to polish out the remaining small scratches and raise the shine. I gave the Cumberland stem several coats of carnauba wax and the bowl several coats of Clapham’s Beeswax/Canuaba Wax then buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. This turned out to be a beautiful Fikri Baki Meerschaum Danish Egg. The finished pipe is shown in the photos below. The dimensions are Length: 6 inches, Height: 2 ¼ inches, Outside diameter of the bowl: 1 ½ inches long by 1 ¼ inches wide, Chamber diameter: 7/8 of an inch. The weight of the pipe is 1.94 ounces/53 grams. Thanks for walking through the restoration with me as I worked this beautiful F. Baki Meerschaum Danish Egg. I will be sending it back very soon to the pipeman who asked me to restore it. Thanks for looking.