Blog by Steve Laug

Last week I received a call from a fellow who was referred to me by our local pipe shop. He had a churchwarden that was stamped Capri [over]Warlock [over] Made in Italy on the underside of the shank. He had broken off the tenon and was not sure how to proceed. We talked about replacing the tenon on the stem and he breathed a sigh of relief. We discussed how to get it to me to work on. He decided he would mail it to me. On Monday this week that package arrived with his pipe. It was a nice looking pipe in many ways. The shank was clear of the broken tenon and the bowl was quite clean. The shank and stem were filthy inside and it is quite clear that he had not cleaned it often. The stem had an acrylic adornment ring on the end that was glued in place. The tenon had broken off just ahead of this ring. It was sharply broken and the airway in the previous tenon had not been centered in the tenon. It was significantly thinner on one side than the other which I think probably was part of the reason for a break. The stem had some light tooth chatter on both sides near the button. I took some photos of the parts of the pipe before I started my work on it.

I took a photo of the stamping on the underside of the shank. It was clear and read as noted above.

I took a photo of the stamping on the underside of the shank. It was clear and read as noted above. I took a photo of the bowl and rim top to show the condition of the bowl when it arrived. I also took a photo of the broken tenon end on the stem.

I took a photo of the bowl and rim top to show the condition of the bowl when it arrived. I also took a photo of the broken tenon end on the stem. The pipe smelled really strong even though the bowl was clean and had no cake. It was filthy in the shank and the airway in the stem. I cleaned both out with 99% isopropyl alcohol, cotton swabs and pipe cleaners. It took some work but it is finally clean and smells fresh.

The pipe smelled really strong even though the bowl was clean and had no cake. It was filthy in the shank and the airway in the stem. I cleaned both out with 99% isopropyl alcohol, cotton swabs and pipe cleaners. It took some work but it is finally clean and smells fresh. I used my Dremel and sanding drum to flatten out the end of the shank and remove the remainder of the broken tenon in preparation for the new tenon. I chose a new tenon from my assortment of them. It was a little large both in terms of the mortise and the shank end but it would work.

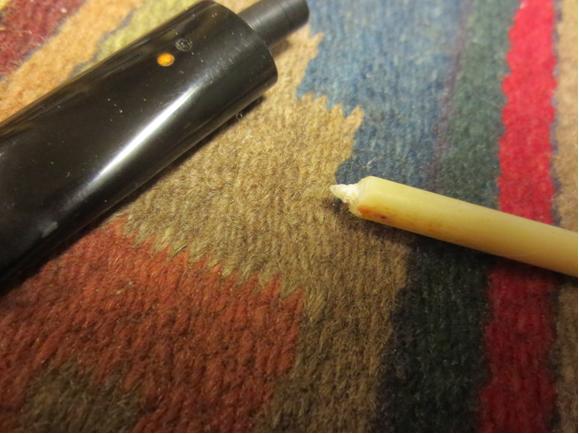

I used my Dremel and sanding drum to flatten out the end of the shank and remove the remainder of the broken tenon in preparation for the new tenon. I chose a new tenon from my assortment of them. It was a little large both in terms of the mortise and the shank end but it would work. I drilled out the airway in the stem with a bit on my cordless drill. Before I drilled it I used a sharp knife to center the airway in the stem and remove the off-center nature. I was able to center it then drilled. I started small and worked my way up to the maximum size the airway would take without weakening the walls of the stem. I used my Dremel and sanding drum to reduce the diameter of both ends of the tenon replacement. I checked it frequently for fit in both the stem and the shank. It took a bit of work but it finally was the right size.

I drilled out the airway in the stem with a bit on my cordless drill. Before I drilled it I used a sharp knife to center the airway in the stem and remove the off-center nature. I was able to center it then drilled. I started small and worked my way up to the maximum size the airway would take without weakening the walls of the stem. I used my Dremel and sanding drum to reduce the diameter of both ends of the tenon replacement. I checked it frequently for fit in both the stem and the shank. It took a bit of work but it finally was the right size. I checked the fit in the stem one final time then glued it in place in the airway with black CA glue. I set it aside over night to let the glue cure.

I checked the fit in the stem one final time then glued it in place in the airway with black CA glue. I set it aside over night to let the glue cure. I polished the stem with micromesh sanding pads to remove the tooth chatter and slight damage that had happened to the ring and the stem when the tenon broke. I dry sanded with 1500-12000 grit pads and wiped the stem down after each sanding pad with Obsidian Oil to protect and preserve the vulcanite.

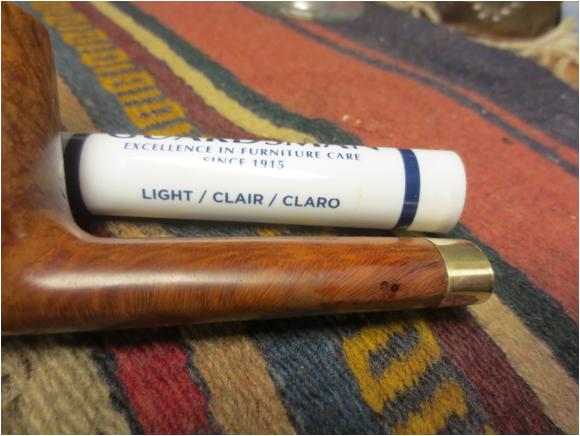

I polished the stem with micromesh sanding pads to remove the tooth chatter and slight damage that had happened to the ring and the stem when the tenon broke. I dry sanded with 1500-12000 grit pads and wiped the stem down after each sanding pad with Obsidian Oil to protect and preserve the vulcanite. I put the pipe back together – the bowl with its repaired stem. This restemmed and restored Capri Warlock (Churchwarden) is a real beauty and I think that the fit of the new tenon works very well. The grain on the bowl came alive with the buffing. I used Blue Diamond on the buffing wheel on both the bowl and stem. I gave both multiple coats of carnauba wax on the wheel then buffed it with a clean buffing pad to raise the shine. I hand buffed it with a microfibre cloth to deepen the shine. The Capri Warlock feels great in the hand. It is lightweight and the contrast in the blacks of the briar, the brown swirled acrylic ring and the polished vulcanite stem looks quite nice. The dimensions of the pipe are Length: 10 inches, Height: 1 ¾ inches, Outer diameter of the bowl: 1 ½ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 2.50 ounces/71 grams. It really is a beauty. I will be packing it up this evening and mailing it out to the fellow soon. I think he will be excited to get it back.Thanks for walking through the replacement of the new tenon and the restoration with me. Cheers.

I put the pipe back together – the bowl with its repaired stem. This restemmed and restored Capri Warlock (Churchwarden) is a real beauty and I think that the fit of the new tenon works very well. The grain on the bowl came alive with the buffing. I used Blue Diamond on the buffing wheel on both the bowl and stem. I gave both multiple coats of carnauba wax on the wheel then buffed it with a clean buffing pad to raise the shine. I hand buffed it with a microfibre cloth to deepen the shine. The Capri Warlock feels great in the hand. It is lightweight and the contrast in the blacks of the briar, the brown swirled acrylic ring and the polished vulcanite stem looks quite nice. The dimensions of the pipe are Length: 10 inches, Height: 1 ¾ inches, Outer diameter of the bowl: 1 ½ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 2.50 ounces/71 grams. It really is a beauty. I will be packing it up this evening and mailing it out to the fellow soon. I think he will be excited to get it back.Thanks for walking through the replacement of the new tenon and the restoration with me. Cheers.