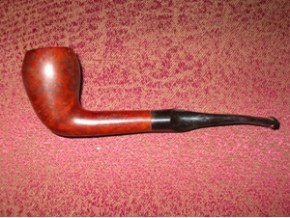

I had this old Danish shaped pipe in my box for refurbishing for some time. I had never heard of the brand but I liked the shape of this particular pipe. It is delicate looking and yet feels comfortable in the hand and mouth. The grain is not remarkable but it is good. It is stamped made in Denmark and I would call it an acorn shape. I always like to do a bit of detective work on the brands I come across and have done a fair bit of research on the web to find out any information. Nothing was found on the web. The stem is a modified saddle bit, pinched at the sides from the top and bottom views but generally tapered to the saddle. It is a slightly bent stem. The bowl was dirty and caked with what smelled like an aromatic tobacco – very vanilla smelling. The stem had a coating of some kind of sticky substance – like scotch tape that had been applied with a price tag. The finish was dirty and the grain appeared smudged beneath the finish. The rim was tarred but not scorched. This was going to be an easy clean up.

I reamed and cleaned the bowl to remove the thick cake. I also filled the bowl with cotton bolls and isopropyl alcohol and let it sit over night to leach out the tars and oils. In the morning I wiped down the outside with alcohol to remove a bit of the darkened finish and grime. I then buffed it and polished it with White Diamond to bring back the shine. I cleaned the stem with isopropyl alcohol to remove the sticky residue on it and then cleaned the inside of the stem with pipe cleaners and alcohol. I buffed away the slight oxidation. I then took the pipe to my buffer and gave it a final buff with White Diamond and then multiple coats of carnauba wax.

Any help on identifying the maker of this pipe would be appreciated. You can post responses here. Thanks ahead of time for your help.