by Steve Laug

The next pipe on the table was a bowl sans stem that I have had in my box of bowls to be restemmed. It is stamped on the left side of the shank and reads ICE AGE and on the underside is stamped the shape number 644. On the acrylic shank extension left side it is stamped Italy and on the underside of the extension it is stamped N. From my previous work on one of these I knew that I was dealing with a Savinelli product. The pipe had been reamed and cleaned by my brother Jeff many years ago. The rusticated rim top had some darkening around the top and the inner edge but otherwise was clean. The finish had been scrubbed and there was a peeling coat of varnish around the sides and heel. The acrylic shank extension was loose and there was a threaded metal tenon that it screwed onto. I would need to align the extension and shape it to fit smoothly with the shank. I found a vulcanite taper stem in my can of stems that would work with some adjustments. It would need some shaping and tapering but the size and shape were perfect to start with. I took some photos of the bowl before I worked on it and the new stem.

I took photos of the stamping on the pipe and the acrylic shank extension. It is clear and readable as noted above. You can see from the photos that the shank extension is snug but does not line up with the round shape of the shank very well. Work will need to be done on it.

I took photos of the stamping on the pipe and the acrylic shank extension. It is clear and readable as noted above. You can see from the photos that the shank extension is snug but does not line up with the round shape of the shank very well. Work will need to be done on it. I adjusted the fit of the shank extension to the shank with 220 grit sandpaper. It took a lot of hand sanding to get the fit correct. It lines up well and the fit to the shank is snug. I glued it in place on the metal tenon in the shank so that the fit did not move.

I adjusted the fit of the shank extension to the shank with 220 grit sandpaper. It took a lot of hand sanding to get the fit correct. It lines up well and the fit to the shank is snug. I glued it in place on the metal tenon in the shank so that the fit did not move.

I wiped the bowl down with acetone on cotton pads to remove the spots of varnish on the bowl and shank. It looked much better when I was finished.

I wiped the bowl down with acetone on cotton pads to remove the spots of varnish on the bowl and shank. It looked much better when I was finished.

I cleaned the rim top with a brass bristle wire brush to remove the debris. It looked much better. I stained the rim top with a black Sharpie Pen. I went over it once again with the brush and it looked much better.

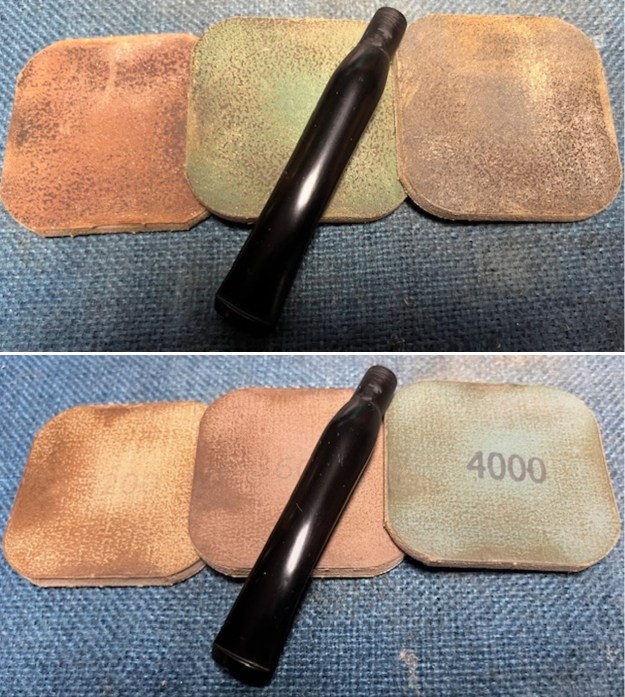

I cleaned the rim top with a brass bristle wire brush to remove the debris. It looked much better. I stained the rim top with a black Sharpie Pen. I went over it once again with the brush and it looked much better. I sanded the bowl and shank extension with 320-3500 grit 2×2 inch sanding pads. I wiped the bowl and shank down with a damp cloth after each sanding pad to remove the sanding debris. The pipe began to look much better.

I sanded the bowl and shank extension with 320-3500 grit 2×2 inch sanding pads. I wiped the bowl and shank down with a damp cloth after each sanding pad to remove the sanding debris. The pipe began to look much better.

I polished the bowl ands shank extension with micromesh sanding pads – wet sanding with 1500-12000 grit pads. I wiped the briar down after each pad with a damp cloth. The bowl is starting to look very good.

I polished the bowl ands shank extension with micromesh sanding pads – wet sanding with 1500-12000 grit pads. I wiped the briar down after each pad with a damp cloth. The bowl is starting to look very good.

I worked some Before & After Restoration Balm into the surface of the briar with my fingertips and into the plateau rim top and shank end with a horsehair shoe brush to clean, enliven and protect it. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

I worked some Before & After Restoration Balm into the surface of the briar with my fingertips and into the plateau rim top and shank end with a horsehair shoe brush to clean, enliven and protect it. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

I turned to the new stem. I went through my can of stems and found a taper stem that would work for the pipe. I gave the stem a smooth angle from the tenon up to the stem. I used a Dremel and sanding drum to give it a new shape.

I turned to the new stem. I went through my can of stems and found a taper stem that would work for the pipe. I gave the stem a smooth angle from the tenon up to the stem. I used a Dremel and sanding drum to give it a new shape. I heated the stem with the flame of a Bic lighter until it softened. I gave it a slight bend so that it followed the flow of the pipe. I sanded the stem with a folded piece of 220 grit sandpaper.

I heated the stem with the flame of a Bic lighter until it softened. I gave it a slight bend so that it followed the flow of the pipe. I sanded the stem with a folded piece of 220 grit sandpaper.

I sanded the stem with 320-3500 grit 2×2 inch sanding pads. I wiped the briar down after each pad with a damp cloth to remove the sanding dust and debris. I wiped it down with an Obsidian Oil cloth. It began to look very good.

I sanded the stem with 320-3500 grit 2×2 inch sanding pads. I wiped the briar down after each pad with a damp cloth to remove the sanding dust and debris. I wiped it down with an Obsidian Oil cloth. It began to look very good. I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with some Obsidian Oil. I finished polishing it with Before & After Pipe Stem Polish – both Fine and Extra Fine and buffed it off with a cotton cloth. I wiped it down with Obsidian Oil to protect the stem and slow down the oxidation.

I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with some Obsidian Oil. I finished polishing it with Before & After Pipe Stem Polish – both Fine and Extra Fine and buffed it off with a cotton cloth. I wiped it down with Obsidian Oil to protect the stem and slow down the oxidation.

This restemmed, smooth Savinelli Made Ice Age 644 Volcano Italy is a beautiful looking pipe that combines a smooth finish with a unique shaped acrylic shank extension. The brown stains on the bowl work well to highlight the finish. I put the newly finished stem on the bowl and buffed it with Blue Diamond on the buffing wheel being careful to not buff the stamping. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing it with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished pipe is quite nice and feels great in the hand. Give the finished pipe a look in the photos below. I can only tell you that like the other pipes I am working that it is much prettier in person than the photos capture. The dimensions of the pipe are Length: 6 inches, Height: 2 inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 54grams/1.90ounces. I will soon be adding it to the Italian Pipe Makers Section of the rebornpipes store. Thanks for walking through the restoration with me as I worked over another beautiful pipe. Remember we are not pipe owners; we are pipemen and women who hold our pipes in trust until they pass on into the trust of the next generation.

This restemmed, smooth Savinelli Made Ice Age 644 Volcano Italy is a beautiful looking pipe that combines a smooth finish with a unique shaped acrylic shank extension. The brown stains on the bowl work well to highlight the finish. I put the newly finished stem on the bowl and buffed it with Blue Diamond on the buffing wheel being careful to not buff the stamping. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing it with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished pipe is quite nice and feels great in the hand. Give the finished pipe a look in the photos below. I can only tell you that like the other pipes I am working that it is much prettier in person than the photos capture. The dimensions of the pipe are Length: 6 inches, Height: 2 inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 54grams/1.90ounces. I will soon be adding it to the Italian Pipe Makers Section of the rebornpipes store. Thanks for walking through the restoration with me as I worked over another beautiful pipe. Remember we are not pipe owners; we are pipemen and women who hold our pipes in trust until they pass on into the trust of the next generation.