by Steve Laug

The next pipe on the work table came to us from a seller in Bristol, Tennessee, USA on 12/13/2024. The pipe is beautifully grained tall and short Stack shaped pipe with what looks like a mix of medium brown stains. The pipe is stamped on the left side of the shank and reads Sunrise [over] Natural. On the right side of the shank it reads Made in England in a circle followed by the shape number 188 near the bowl shank junction. The pipe was very dirty with a lot of grime ground into the bowl with grain peeking through in spots. The bowl was heavily caked with a lava coat flowing onto the rim top and inner around the bowl. The stem was did not fit well in the shank. It was oxidized, calcified and dirty with light tooth chatter and marks on the top and underside near the button. The stem had deep gouges around the shank end and appeared to have been damaged by someone trying to turn it with pliers. It was a mess. The pipe definitely had promise but it was very dirty. Jeff took some photos of the pipe before he started his cleanup work.

He took photos of the rim top and bowl to give a clear picture of the thickness of the cake and well as the lava and darkening on the rim top and inner edge. He also took photos of the top and underside of the stem to show the oxidation and the chatter and tooth marks. The first stem photo shows some of the damage on the vulcanite surface at the shank end.

He took photos of the rim top and bowl to give a clear picture of the thickness of the cake and well as the lava and darkening on the rim top and inner edge. He also took photos of the top and underside of the stem to show the oxidation and the chatter and tooth marks. The first stem photo shows some of the damage on the vulcanite surface at the shank end.

Jeff took a photo the sides and heel of the bowl to give a picture of the condition of the bowl and shank. You can see in the photos the damage and roughness to the outer edge of the bowl all the way around. It really is a mess.

Jeff took a photo the sides and heel of the bowl to give a picture of the condition of the bowl and shank. You can see in the photos the damage and roughness to the outer edge of the bowl all the way around. It really is a mess.

The stamping on the sides of the shank is readable and reads as noted above.

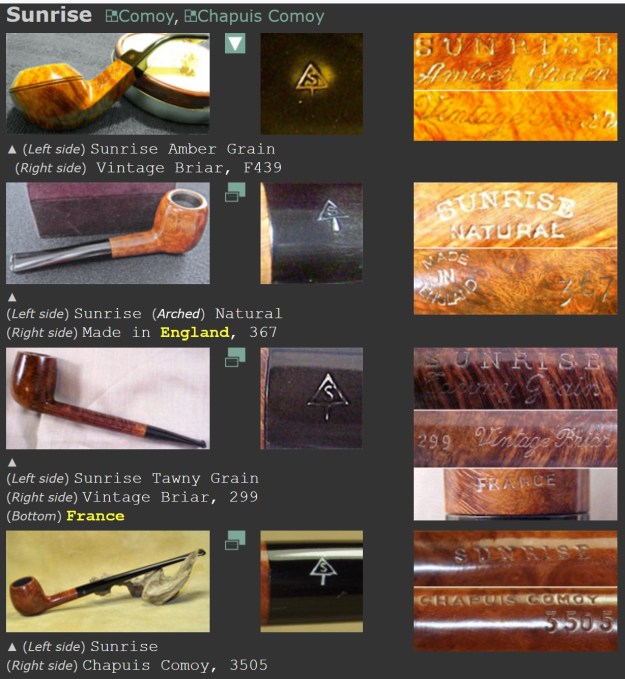

The stamping on the sides of the shank is readable and reads as noted above.  If my memory served me correctly this pipe was Comoy’s made pipe and the France stamp on the shank pointed me to the connection between London and St. Claude. I turned to Pipephil’s site (http://www.pipephil.eu/logos/en/logo-s13.html) to get some background information on this beauty. I have included a screen capture of the pertinent section.

If my memory served me correctly this pipe was Comoy’s made pipe and the France stamp on the shank pointed me to the connection between London and St. Claude. I turned to Pipephil’s site (http://www.pipephil.eu/logos/en/logo-s13.html) to get some background information on this beauty. I have included a screen capture of the pertinent section.  The side bar includes this interesting piece of information. I quote:

The side bar includes this interesting piece of information. I quote:

The Sunrise brand perfectly illustrates the split pipe production of a same label between Saint Claude (FR) and London (GB) during the period Chapuis Comoy and Comoy closely collaborated (prior to early 1970s).

I turned to Pipedia and looked under the French makers and the brand was not listed. Under the English makers it was listed as a Comoy’s Sub-brand or second. I turned to the Comoy’s listing and at the bottom of the article was a list of these pipes (https://pipedia.org/wiki/Comoy%27s). I have included the list in its entirety and highlighted the Sunrise in red.

Seconds made by Comoy’s

Ace of spades, Ancestor, Astor, Ayres, Britannia, Carlyle, Charles Cross, Claridge, Coronet?, Cromwell, Dorchester, Dunbar, Drury Lane, Emerson, Everyman, Festival of Britain, Golden Arrow, Grand Master, Gresham, Guildhall, Hamilton (according to Who Made That Pipe), Kingsway, Lion’s Head, Lord Clive, Lumberman, Hyde Park, Lloyds, Mc Gahey, Moorgate, Newcastle, Oxford, O’Gorman, Rosebery Extra, Royal Falcon, Royal Guard, Royal Lane, Scotland Yard, St James, Sunrise, Super Sports, Sussex, The Academy Award, The Golden Arrow, The Mansion House, The Exmoor Pipe, Throgmorton, Tinder Box Royal Coachman, Townhall, Trident, Trocadero, Westminster, Wilshire

Now it was time to turn my attentions to the pipe itself. Jeff had cleaned up the pipe with his usual penchant for thoroughness. He reamed the pipe with a PipNet pipe reamer and removed the rest of it with a Savinelli Fitsall Pipe Knife. He scrubbed the bowl with undiluted Murphy’s Oil Soap with a tooth brush. He rinsed it under running warm water to remove the soap and grime. He cleaned out the inside of the shank and the airway in the stem with alcohol, cotton swabs and pipe cleaners. He soaked the stem in Before & After Deoxidizer and rinsed it off with warm water. I took photos of the pipe once I received it.

The rim top cleaned up really well. The rim top and outer edge of the bowl are clean but clearly show the damaged top and outer edge. The stem photos show the damage on the shank end surface of the stem surface from pliers and also tooth marks on the stem on both sides that will need to be repaired.

The rim top cleaned up really well. The rim top and outer edge of the bowl are clean but clearly show the damaged top and outer edge. The stem photos show the damage on the shank end surface of the stem surface from pliers and also tooth marks on the stem on both sides that will need to be repaired.  The stamping on the left and right sides of the shank is faint and readable and reads as noted above. There was also a stamp on the left side of the stem that is the triangle S with a stem logo of the Sunrise pipes. I removed the stem and took a photo of the pipe to give a sense of the whole. The bowl looked very good and once I cleaned up the stem the pipe would look very good.

The stamping on the left and right sides of the shank is faint and readable and reads as noted above. There was also a stamp on the left side of the stem that is the triangle S with a stem logo of the Sunrise pipes. I removed the stem and took a photo of the pipe to give a sense of the whole. The bowl looked very good and once I cleaned up the stem the pipe would look very good.

I sanded the briar bowl with 320-3500 grit 2×2 inch sanding pads. I worked over the rim top and edges of the bowl at the same time. I used some 220 to trouble shoot small portions of the outer edges that were damaged. I wiped the bowl down after each sanding pad with a damp cloth to remove the sanding debris and dust from the clean up.

I sanded the briar bowl with 320-3500 grit 2×2 inch sanding pads. I worked over the rim top and edges of the bowl at the same time. I used some 220 to trouble shoot small portions of the outer edges that were damaged. I wiped the bowl down after each sanding pad with a damp cloth to remove the sanding debris and dust from the clean up.

I polished the briar with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with a damp cloth after each sanding pad. The grain really began to stand out by the final pads.

I polished the briar with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with a damp cloth after each sanding pad. The grain really began to stand out by the final pads.

I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips to clean, enliven and protect the briar. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine.

I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips to clean, enliven and protect the briar. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine.

I set the bowl aside and turned my attention to the stem. I filled in the deep gouges in the stem surface with black rubberized CA glue. The from the previous owners use of pliers to remove the stem had left these deep marks. Once the repairs cured I used folded 220 grit sandpaper to blend them into the surface. It was a lot of sanding but well worth the effort.

I set the bowl aside and turned my attention to the stem. I filled in the deep gouges in the stem surface with black rubberized CA glue. The from the previous owners use of pliers to remove the stem had left these deep marks. Once the repairs cured I used folded 220 grit sandpaper to blend them into the surface. It was a lot of sanding but well worth the effort.

I followed that by sanding it with 320-3500 grit sanding pads to further blend repaired areas. I wiped the stem down between pads with an Obsidian Oil cloth to remove the sanding debris from the stem.

I followed that by sanding it with 320-3500 grit sanding pads to further blend repaired areas. I wiped the stem down between pads with an Obsidian Oil cloth to remove the sanding debris from the stem. I touched up the stamp on the left side of the stem with white acrylic nail polish and removed the excess with the sanding pads above. It is faint in spots but it is very readable with the white acrylic.

I touched up the stamp on the left side of the stem with white acrylic nail polish and removed the excess with the sanding pads above. It is faint in spots but it is very readable with the white acrylic.  The stem looked much better at this point so I polished it with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem. I gave it another coat of Obsidian Oil to end the polishing at this point.

The stem looked much better at this point so I polished it with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem. I gave it another coat of Obsidian Oil to end the polishing at this point.

This Comoy’s Made Sunrise Natural 188 Stack is a great looking pipe now that it has been restored. The smooth brown stained finish around the bowl is quite beautiful and highlights the grain. The finish works well with the polished vulcanite taper stem. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Sunrise Natural 188 Stack sits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 2 ¼ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ inch. The weight of the pipe is 1.66 ounces/47 grams. I will be putting it on the rebornpipes store in the British Pipemakers Section shortly. If you are interested in adding this pipe to your collection send me a message or an email. Thanks for reading this blog and my reflections on the pipe while I worked on it.

This Comoy’s Made Sunrise Natural 188 Stack is a great looking pipe now that it has been restored. The smooth brown stained finish around the bowl is quite beautiful and highlights the grain. The finish works well with the polished vulcanite taper stem. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Sunrise Natural 188 Stack sits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 2 ¼ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ inch. The weight of the pipe is 1.66 ounces/47 grams. I will be putting it on the rebornpipes store in the British Pipemakers Section shortly. If you are interested in adding this pipe to your collection send me a message or an email. Thanks for reading this blog and my reflections on the pipe while I worked on it.