by Steve Laug

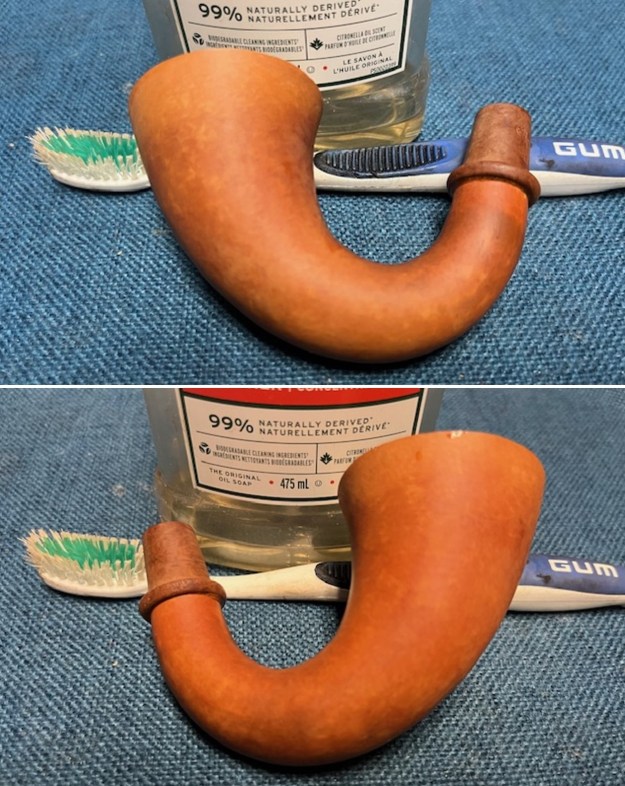

The next pipe came to us from an antique store in Vancouver, Washington, USA on 10/20/2022. It is mixed finish Freehand pipe that feels great in the hand. Even though it was dirty it had some charm showing through the grit and grime of the years. The grain on the smooth top half of the bowl and panel on the shank is quite nice. The sandblast is deep and revealing around the lower part of the bowl and shank. On the underside of the shank it was stamped Bjarne [over] Hand-Carved [over] Made in Denmark. The finish is filthy with dust and grit ground into the briar of the bowl and shank sides. The bowl had a thick cake and heavy overflow of lava on the plateau rim top and inner edge. The variegated brown acrylic stem dirty and had tooth marks and chatter on both sides ahead of the button. The interior of the stem and shank were quite dirty with tars and oils. Jeff took some photos of the pipe to show its overall condition before he started his cleanup work.

He took photos of the rim top and bowl to give a clear picture of the good the pipe bowl looked inside. The rim and the inner edge were heavily coated with thick lava. It still appeared to be in good condition under the lava coat. The photos show the contrast of the bowl’s general condition with the overall condition of the fancy acrylic saddle stem surface.

He took photos of the rim top and bowl to give a clear picture of the good the pipe bowl looked inside. The rim and the inner edge were heavily coated with thick lava. It still appeared to be in good condition under the lava coat. The photos show the contrast of the bowl’s general condition with the overall condition of the fancy acrylic saddle stem surface.

Jeff took photos of the sides and heel of the bowl and shank to give a picture of what the mixed finish of sandblast and smooth looked like on the bowl. The grit and grime on the finish is very obvious in the photos below.

Jeff took photos of the sides and heel of the bowl and shank to give a picture of what the mixed finish of sandblast and smooth looked like on the bowl. The grit and grime on the finish is very obvious in the photos below.

Jeff took photos of the sides and heel of the bowl and shank to give a picture of what the mixed finish of sandblast and smooth looked like on the bowl. The grit and grime on the finish is very obvious in the photos below.

Jeff took photos of the sides and heel of the bowl and shank to give a picture of what the mixed finish of sandblast and smooth looked like on the bowl. The grit and grime on the finish is very obvious in the photos below. I turned to my favourite go to sites on the background of brands. The first is Pipephil’s site (http://www.pipephil.eu/logos/en/logo-b5.html). There I looked up the Bjarne brand. I have copied the pertinent information below.

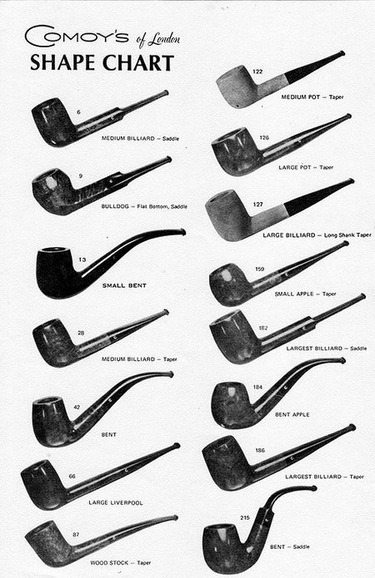

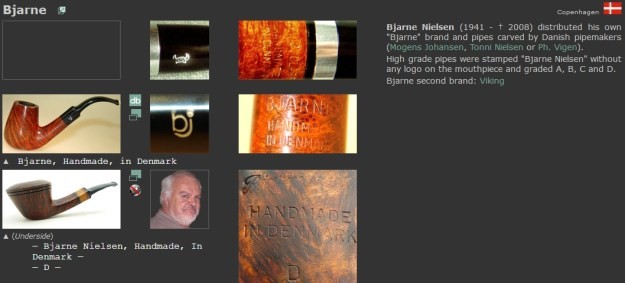

I turned to my favourite go to sites on the background of brands. The first is Pipephil’s site (http://www.pipephil.eu/logos/en/logo-b5.html). There I looked up the Bjarne brand. I have copied the pertinent information below.

Bjarne Nielsen (1941 – † 2008) distributed his own “Bjarne” brand and pipes carved by Danish pipemakers (Mogens Johansen, Tonni Nielsen or Ph. Vigen). High grade pipes were stamped “Bjarne Nielsen” without any logo on the mouthpiece and graded A, B, C and D. Bjarne second brand: Viking.

I have included a screen capture of the section on the brand below.  I turned to Pipedia and looked up the brand for a bit more information on the pipes that were stamped like the one that I am working on (https://pipedia.org/wiki/Bjarne). It is a great history of the brand and a good read. Toward the end of the article I found what I was looking for. I quote:

I turned to Pipedia and looked up the brand for a bit more information on the pipes that were stamped like the one that I am working on (https://pipedia.org/wiki/Bjarne). It is a great history of the brand and a good read. Toward the end of the article I found what I was looking for. I quote:

Among the pipemakers that worked for Bjarne were Johs (for the lower priced high volume pieces), and makers like Ph. Vigen, Ole Bandholm and Tonni Nielsen for high grade pieces. The cheaper line was stamped “Bjarne” while the highest grades were stamped “Bjarne Nielsen” (never with the pipemakers’ name) and graded, from highest to lowest, by the letters: AX, A, B, C, D, E, F, G, H, I, and J.

Now I knew that I was dealing with the cheaper line of pipe made by the company. It was stamped Bjarne while the higher grade pipes were stamped Bjarne Nielsen with a grade stamp. Now it was time to work on the pipe.

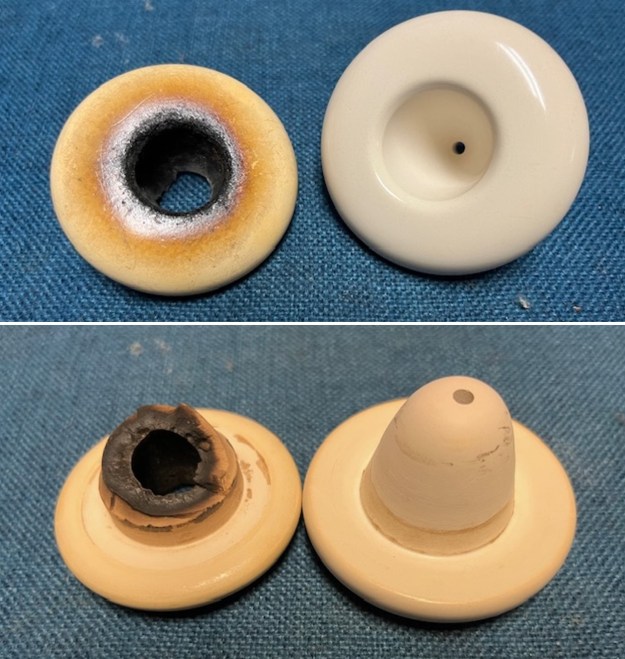

Jeff had cleaned up the pipe with his usual penchant for thoroughness. He reamed the pipe with a PipNet Pipe Reamer and cleaned up the remnants with a Savinelli Fitsall Pipe Knife. He scrubbed the bowl with undiluted Murphy’s Oil Soap with a tooth brush. He worked over the debris on the plateau rim top and was able to remove it. He rinsed it under running warm water to remove the soap and grime. He cleaned out the inside of the shank and the airway with alcohol, cotton swabs and pipe cleaners. I took photos of the pipe bowl once I received it. It really looked good.

The bowl looked very good though there was some darkening and damage on the plateau rim top. The inner and outer edges of the rim looked to be in good condition. The stem looks really quite good. There were some tooth marks and chatter on both sides near the button.

The bowl looked very good though there was some darkening and damage on the plateau rim top. The inner and outer edges of the rim looked to be in good condition. The stem looks really quite good. There were some tooth marks and chatter on both sides near the button. I took a photo of the stamping on the underside of the shank. It was clear and read as noted above. I took the stem off the shank and took a picture of the pipe to give a sense of its overall look. It is going to be a great looking pipe once the restoration is finished.

I took a photo of the stamping on the underside of the shank. It was clear and read as noted above. I took the stem off the shank and took a picture of the pipe to give a sense of its overall look. It is going to be a great looking pipe once the restoration is finished. I decided to begin my work on the pipe by dealing with the darkening and damage to the plateau rim top. I worked it over with a brass bristle wire brush to knock off the grit in the grooves of the plateau and the dark coat on the high spots. When I was finished it looked a lot better than when I started.

I decided to begin my work on the pipe by dealing with the darkening and damage to the plateau rim top. I worked it over with a brass bristle wire brush to knock off the grit in the grooves of the plateau and the dark coat on the high spots. When I was finished it looked a lot better than when I started.  I rubbed the bowl down with Before & After Restoration Balm. I worked it into the smooth surface of the bowl sides and shank with my fingertips and into the plateau rim top, shank end and the sandblast finish with a shoe brush. The product works to clean, enliven and protect the briar. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine.

I rubbed the bowl down with Before & After Restoration Balm. I worked it into the smooth surface of the bowl sides and shank with my fingertips and into the plateau rim top, shank end and the sandblast finish with a shoe brush. The product works to clean, enliven and protect the briar. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine.

I set the bowl aside and turned my attention to the issues with the stem. I filled in the deep tooth marks on the top and underside ahead of the button with clear CA glue. I set it aside to cure. Once it cured, I flattened the repairs with two small files\. I smoothed out the repairs with 220 grit sandpaper to further blend them into the surface of the stem. It was looking very good.

I set the bowl aside and turned my attention to the issues with the stem. I filled in the deep tooth marks on the top and underside ahead of the button with clear CA glue. I set it aside to cure. Once it cured, I flattened the repairs with two small files\. I smoothed out the repairs with 220 grit sandpaper to further blend them into the surface of the stem. It was looking very good.

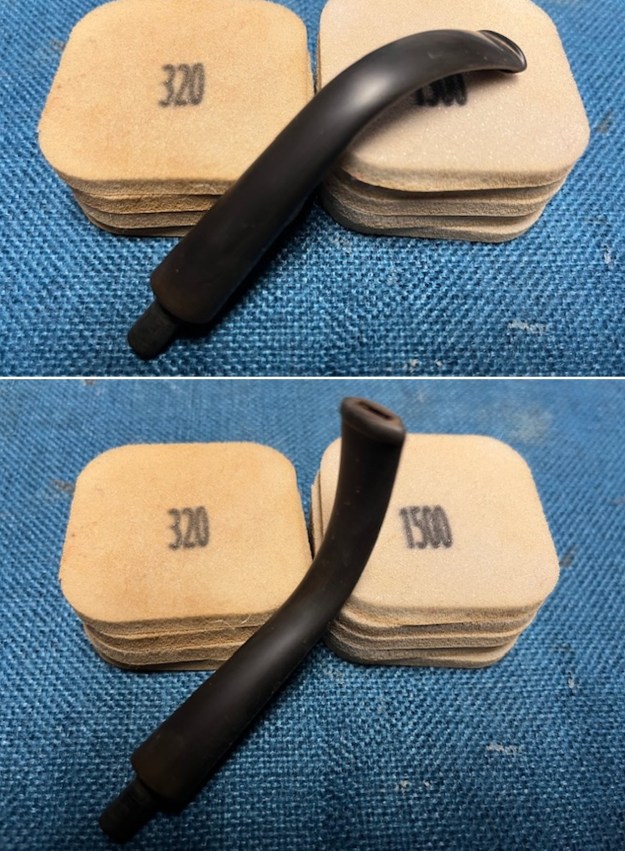

I sanded the stem surface further with 320-3500 grit sanding pads to smooth out the repairs and blend them into the stem surface. I wiped it down after each sanding pad with a damp cloth to remove the sanding debris and dust. It began to look very good.

I sanded the stem surface further with 320-3500 grit sanding pads to smooth out the repairs and blend them into the stem surface. I wiped it down after each sanding pad with a damp cloth to remove the sanding debris and dust. It began to look very good. The stamping on the left side of the saddle stem was faint but I touched up what remained with white acrylic fingernail polish. I used a tooth pick to work it into the stamp. I sanded it with a worn 1500 grit sanding pad and buffed it with a soft cloth.

The stamping on the left side of the saddle stem was faint but I touched up what remained with white acrylic fingernail polish. I used a tooth pick to work it into the stamp. I sanded it with a worn 1500 grit sanding pad and buffed it with a soft cloth. I polished the scratches out of the stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with a damp cloth after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

I polished the scratches out of the stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with a damp cloth after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

This smooth finished Bjarne Hand-Carved Mixed Finish Freehand is a great looking pipe. It is a pipe made in Denmark. The fancy, saddle brown variegated acrylic stem works well and goes nicely with the browns of briar. I put the stem back on the bowl and buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Bjarne Plateau Rim top Freehand fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 inches, Height: 2 inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 49 grams/1.73 ounces. I will be adding it to the rebornpipes store shortly in the Danish Pipe Makers Section. Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!

This smooth finished Bjarne Hand-Carved Mixed Finish Freehand is a great looking pipe. It is a pipe made in Denmark. The fancy, saddle brown variegated acrylic stem works well and goes nicely with the browns of briar. I put the stem back on the bowl and buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Bjarne Plateau Rim top Freehand fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 inches, Height: 2 inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 49 grams/1.73 ounces. I will be adding it to the rebornpipes store shortly in the Danish Pipe Makers Section. Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!