by Steve Laug

The next pipe I chose to work on was one that we purchased on 10/20/2022 from and Antique Store in Vancouver, Washington, USA. This one is stamped Bjarne [over] Handmade [over] In Denmark. I have worked on quite a few Bjarne pipes over the years and found them to be well made pipes following the grain on the smooth and unique sandblast on the others. So, when I saw this one I was excited to work on it. The pipe is kind of a shape I would call a combination of a Freehand and a Panel Brandy. The briar bowl and shank were smooth and well grained. The rim top had a plateau finish. The exterior of the pipe is dirty from use with oils and grime on the bowl sides. It has a thick cake in the bowl and an overflow of lava on the plateau rim top and inner edge of the bowl. The stem is a oval taper stem that is comfortable. It is oxidized but free of tooth marks and chatter on the surface.

Jeff took photos of the rim top and stem to show the general condition of the pipe. The bowl is thickly caked and seems to have a thick dottle in the bottom of the bowl. There was some thick lava on the rim top and inner edge. I am hoping that once the lava is removed the edge will be okay. The stem looked surprisingly good under the dirt and grime. There was oxidation, calcification on the surface of the vulcanite. It looked like it had a rubber Softee Bit on the stem. There did not appear to be any tooth marks or chatter. It should cleanup very well.

Jeff took photos of the rim top and stem to show the general condition of the pipe. The bowl is thickly caked and seems to have a thick dottle in the bottom of the bowl. There was some thick lava on the rim top and inner edge. I am hoping that once the lava is removed the edge will be okay. The stem looked surprisingly good under the dirt and grime. There was oxidation, calcification on the surface of the vulcanite. It looked like it had a rubber Softee Bit on the stem. There did not appear to be any tooth marks or chatter. It should cleanup very well.

Jeff took photos of the bowl sides and heel to show the beautiful grain that was around this bowl event though it was lost in the grime the finish. The pipe had obviously been well loved and enjoyed by the previous pipeman.

Jeff took photos of the bowl sides and heel to show the beautiful grain that was around this bowl event though it was lost in the grime the finish. The pipe had obviously been well loved and enjoyed by the previous pipeman.

He took a photo of the underside of the shank to show the stamping. The stamping is clear and readable in the photos below as noted above. The stem had a faint Bjarne logo on the topside.

He took a photo of the underside of the shank to show the stamping. The stamping is clear and readable in the photos below as noted above. The stem had a faint Bjarne logo on the topside.

In a previous blog I had researched the brand quite a bit. I have included it in full below for information on this pipe (https://rebornpipes.com/2020/03/07/another-pipe-from-the-eastern-canada-lot-a-hand-carved-bjarne-freehand/). I quote:

In a previous blog I had researched the brand quite a bit. I have included it in full below for information on this pipe (https://rebornpipes.com/2020/03/07/another-pipe-from-the-eastern-canada-lot-a-hand-carved-bjarne-freehand/). I quote:

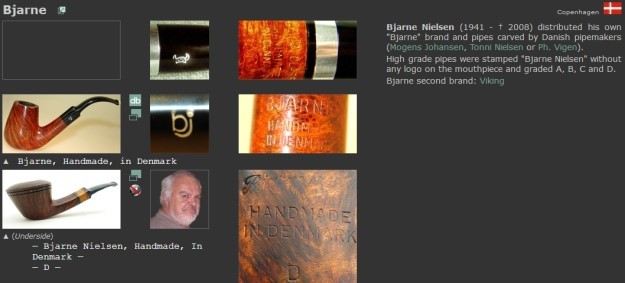

I turned my favourite go to sites on background of brands. The first is Pipephil’s site (http://www.pipephil.eu/logos/en/logo-b5.html). There I looked up the Bjarne brand. I have copied the pertinent information below.

Bjarne Nielsen (1941 – † 2008) distributed his own “Bjarne” brand and pipes carved by Danish pipemakers (Mogens Johansen, Tonni Nielsen or Ph. Vigen). High grade pipes were stamped “Bjarne Nielsen” without any logo on the mouthpiece and graded A, B, C and D. Bjarne second brand: Viking.

I have included a screen capture of the section on the brand below. I turned to Pipedia and looked up the brand for a bit more information on the pipes that were stamped like the one that I am working on (https://pipedia.org/wiki/Bjarne). Toward the end of the article I found what I was looking for. I quote:

I turned to Pipedia and looked up the brand for a bit more information on the pipes that were stamped like the one that I am working on (https://pipedia.org/wiki/Bjarne). Toward the end of the article I found what I was looking for. I quote:

Among the pipemakers that worked for Bjarne were Johs (for the lower priced high volume pieces), and makers like Ph. Vigen, Ole Bandholm and Tonni Nielsen for high grade pieces. The cheaper line was stamped “Bjarne” while the highest grades were stamped “Bjarne Nielsen” (never with the pipemakers’ name) and graded, from highest to lowest, by the letters: AX, A, B, C, D, E, F, G, H, I, and J.

Now I knew that I was dealing with the cheaper line of pipe made by the company. It was stamped Bjarne while the higher grade pipes were stamped Bjarne Nielsen with a grade stamp.

Jeff did a great job cleaning off the debris and grime on this old. He reamed it with a PipNet reamer and smoothed the walls of the bowl with a Savinelli Fitsall pipe knife. He scrubbed out the mortise and the airway in the shank and the stem with alcohol, cotton swabs and pipe cleaners. He scrubbed the exterior of the bowl, rim and shank with a tooth brush and Murphy’s Oil Soap to the oils and tars on the bowl, rim and shank. He rinsed it under running water. He dried it off with a soft cloth. Once the grime was removed the finish underneath was in stellar condition. The rich patina of the older briar was a variegated finish of smooth and sandblast looked great. He scrubbed the exterior of the stem with Soft Scrub then soaked it in a bath of Briarville’s Pipe Stem Deoxidizer. He rinsed off the deoxidizer with warm water and wiped the bowl and stem down with a light coat of olive oil to rehydrate both. The pipe really was quite stunning. I took photos of the pipe to show its condition before I started my work on it.

I took a close up photo of the rim top and edges to show how well it had cleaned up and the edges around the bowl. I also took close up photos of the stem to show the light tooth chatter on the surface ahead of the button on both sides.

I took a close up photo of the rim top and edges to show how well it had cleaned up and the edges around the bowl. I also took close up photos of the stem to show the light tooth chatter on the surface ahead of the button on both sides. I took a photo of the stamping on the underside of the shank. It is faint but readable as noted above. I removed the stem and took a photo of the faint stamping on the top of the stem – BJ. There is not enough depth in the stamp to recolour it.

I took a photo of the stamping on the underside of the shank. It is faint but readable as noted above. I removed the stem and took a photo of the faint stamping on the top of the stem – BJ. There is not enough depth in the stamp to recolour it. I started my work on the pipe by going over the rim top with a wire brush to remove the remnants of debris and lava on the plateau of the rim top.

I started my work on the pipe by going over the rim top with a wire brush to remove the remnants of debris and lava on the plateau of the rim top.  I sanded the bowl with 320-3500 grit sanding pads to remove the scratches and marks on the sides of the bowl and heel. I wiped the bowl down with a damp cloth after each sanding pad to remove the sanding debris. It began to really take on a shine.

I sanded the bowl with 320-3500 grit sanding pads to remove the scratches and marks on the sides of the bowl and heel. I wiped the bowl down with a damp cloth after each sanding pad to remove the sanding debris. It began to really take on a shine.

I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped the bowl down with a damp cloth after each sanding pad. The grain really began to sing.

I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped the bowl down with a damp cloth after each sanding pad. The grain really began to sing.

I worked some Before & After Restoration Balm into the surface of the briar with my fingertips to clean, enliven and protect the briar. I used a shoe brush to work the balm into the plateau on the rim top. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

I worked some Before & After Restoration Balm into the surface of the briar with my fingertips to clean, enliven and protect the briar. I used a shoe brush to work the balm into the plateau on the rim top. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

I set the bowl aside and turned my attention to the stem. I sanded out the tooth marks and dents in the vulcanite with 220 grit sandpaper until it was smooth.

I set the bowl aside and turned my attention to the stem. I sanded out the tooth marks and dents in the vulcanite with 220 grit sandpaper until it was smooth.  I sanded the stem with 320-3500 grit sanding pads to remove the remnants of oxidation and the sanding marks in the vulcanite. I wiped the stem down after each sanding pad with a damp cloth to remove the sanding debris.

I sanded the stem with 320-3500 grit sanding pads to remove the remnants of oxidation and the sanding marks in the vulcanite. I wiped the stem down after each sanding pad with a damp cloth to remove the sanding debris. I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine. I gave it another coat of Obsidian Oil.

I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine. I gave it another coat of Obsidian Oil.

I am really happy with the way that this Bjarne Hand Made Freehand Brandy Panel turned out. It really is a beautiful looking pipe with a unique shape and smooth and plateau finishes. The vulcanite oval taper stem is really nice. The briar really came alive with the buffing. The rich brown and black stains of the finish gave the pipe a sense of depth with the polishing and waxing. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Bjarne Brandy Panel Freehand really is a beauty and feels great in the hand and looks very good. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 2 inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 50 grams/1.66 ounces. The pipe will be going on the rebornpipes store in the Danish Pipe Makers Section if you would like to add it to your collection. Thanks for reading this blog and my reflections on the pipe while I worked on it. It was a fun one to work on!

I am really happy with the way that this Bjarne Hand Made Freehand Brandy Panel turned out. It really is a beautiful looking pipe with a unique shape and smooth and plateau finishes. The vulcanite oval taper stem is really nice. The briar really came alive with the buffing. The rich brown and black stains of the finish gave the pipe a sense of depth with the polishing and waxing. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Bjarne Brandy Panel Freehand really is a beauty and feels great in the hand and looks very good. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 2 inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 50 grams/1.66 ounces. The pipe will be going on the rebornpipes store in the Danish Pipe Makers Section if you would like to add it to your collection. Thanks for reading this blog and my reflections on the pipe while I worked on it. It was a fun one to work on!