by Steve Laug

The next pipe I chose to work on was one that we purchased on 12/28/2024 from as part of an estate that belonged to a pipeman and carver, Byron Harwood from Missoula, Montana, USA. This one is stamped Rad Davis [over] Hand Made [over] USA. I have a few of Rad’s pipes in my own collection and all are amazing smokers and well laid out pipes following the grain on the smooth and unique sandblast on the others. So, when I saw this one in the lot I was excited to work on it. The pipe is kind of a shape I would call a combination of a Freehand Apple or maybe even a Prince. The briar bowl and shank were smooth and well grained. There are a couple of flaws – one on the underside of the shank at the spot it joins the bowl and the second one on the backside of the bowl. The rim top was smooth and there was a plateau finish on the shank end. The exterior of the pipe is dirty from use with oils and grime on the bowl sides. It has a thick cake in the bowl and an overflow of lava on the rim top and inner edge of the bowl. The stem is a fancy saddle stem that is often used on Freehand pipes. It is oxidized but free of tooth marks and chatter on the surface.

Jeff took photos of the rim top and stem to show the general condition of the pipe. The bowl is thickly caked with some lava on the rim top and inner edge. I am hoping that once the lava is removed the edge will be okay. The stem looked surprisingly good under the dirt and grime and light oxidation on the surface of the vulcanite. It should cleanup very well.

Jeff took photos of the rim top and stem to show the general condition of the pipe. The bowl is thickly caked with some lava on the rim top and inner edge. I am hoping that once the lava is removed the edge will be okay. The stem looked surprisingly good under the dirt and grime and light oxidation on the surface of the vulcanite. It should cleanup very well.

Jeff took photos of the bowl sides and heel to show the beautiful grain that was around this bowl. There was some light grime in the finish but otherwise it was quite clean.

Jeff took photos of the bowl sides and heel to show the beautiful grain that was around this bowl. There was some light grime in the finish but otherwise it was quite clean.

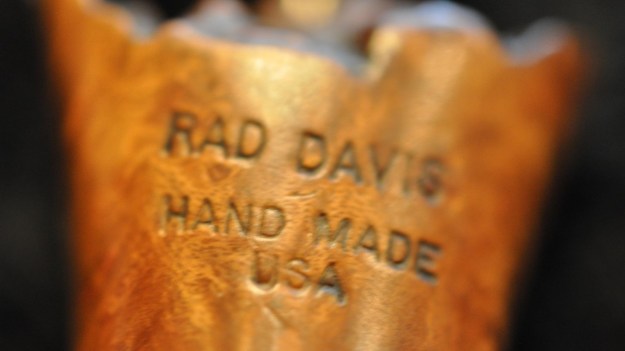

He took a photo of the underside of the shank to show the stamping. The stamping is clear and readable in the photos below as noted above. The stem did not have any stamping or logo on it.

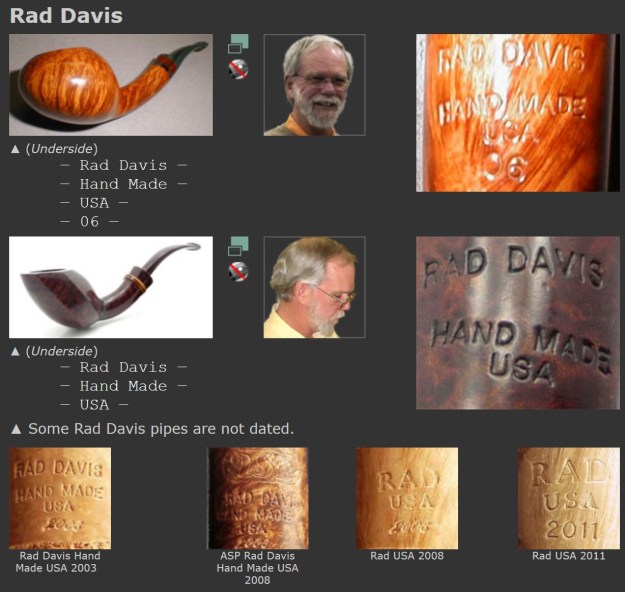

He took a photo of the underside of the shank to show the stamping. The stamping is clear and readable in the photos below as noted above. The stem did not have any stamping or logo on it. I turned to Pipephil to get a quick overview of the brand. I have done a screen capture of the section on the site that was pertinent (http://www.pipephil.eu/logos/en/logo-r1.html#raddavis). I also included the sidebar notes on the page.

I turned to Pipephil to get a quick overview of the brand. I have done a screen capture of the section on the site that was pertinent (http://www.pipephil.eu/logos/en/logo-r1.html#raddavis). I also included the sidebar notes on the page.  Artisan: Robert (Rad) Davis began making and selling freehand pipes in 2003.

Artisan: Robert (Rad) Davis began making and selling freehand pipes in 2003.

I turned to Pipedia where Rad had written the entry about himself and his pipemaking work (https://pipedia.org/wiki/Davis,_Rad). It a great read and I have included it in its entirety.

I have been smoking (off and on) and collecting (continuously) pipes since the early 1970’s. They have always fascinated me. My very first pipe was a Pioneer Calabash that I bought in a department store in the early 70’s while I was in college in Sacramento, California. My second pipe during that same period was a Nording free hand that I got for $20.00 plus a coupon from the back of an Amphora Pipe Tobacco package. The coupon was introducing this new young Danish pipe maker to the U.S. market. I still have both pipes.

I met Mark Tinsky several years ago in the internet when I was in need of a pipe repair, and from his site I found that he was a fly fisherman. I am a fly fishing guide in Montana and a commercial fly tier, and we ended up trading some flies for pipe repair. Last spring, I was in need of a pipe repair again, and when I found Mark’s site, I saw that he had a new address in Helena, Montana, where I live and guide during the summer! We got together after I arrived for the season and did some fishing together, and he showed me his shop, and even made me a nice bent Rhodesian pipe while I watched. It’s become one of my favorite pipes, dedicated to Mac Baren Navy Flake.

When I expressed an interest in trying to make a pipe, Mark was much more than helpful. He gave me a couple of pipe kits that he couldn’t sell for one reason or another, cut the basic shape out on the band saw, and let me go to work making free hand pipes. My first few pipes left a lot to be desired, but I was starting to see what I was doing wrong and concentrated more on getting the proportions and flow of the shape right until I was turning out some decent work. I also learned to cut and drill pipes and turn tenons on stems during this time. I discussed with Mark the possibility of my actually selling my pipes, and he said that he thought there was a definite need for quality hand made pipes at reasonable prices.

And here is the result. All my pipes are free hands, made from the same high quality Grecian Briar used by Mark. There are no fills in my pipes. Some may have small flaws, but they are not hidden, and they are priced accordingly.[1]

I sent Rad Davis a message on Facebook regarding the pipe to see if I could learn about when he made it. Rad kindly answered me. Here is his answer:

Hi Steve, I can’t remember that one in particular, but I can tell you that it was early on in my pipe making career, back when I was making freehands with premade stems.

This confirmed my thinking that it was an early pipe. It was also good to know that the stem was original and not a replacement. Now it was time to work on the pipe itself.

Jeff had done a great job cleaning up the pipe as usual. He reamed the pipe with a PipNet reamer and cut back the cake back to the bare briar. He cleaned up the walls with a Savinelli Fitsall Pipe Knife. Surprisingly the walls looked unscathed from the heavy cake. He scrubbed the interior of the bowl and shank with pipe cleaners, cotton swabs and alcohol to remove the tars and oils. He scrubbed the exterior of the pipe with Murphy’s Oil Soap and a tooth brush to remove the grime from the finish. He scrubbed the inside of the stem with alcohol, cotton swabs and pipe cleaners. He scrubbed the exterior of the stem with Soft Scrub and then soaked it in Briarville’s Deoxidizer. He washed it off with warm water to remove the Deoxidizer. When I examined the stem, it looked very good. The pipe looked far better when it arrived.

I took some close up photos of the rim top and edges to show how well it had cleaned up and the edges around the bowl. I also took close up photos of the stem to show the light tooth chatter on the surface ahead of the button on both sides.

I took some close up photos of the rim top and edges to show how well it had cleaned up and the edges around the bowl. I also took close up photos of the stem to show the light tooth chatter on the surface ahead of the button on both sides. I took a photo of the stamping on the underside of the shank. It is clear and readable as noted above. I removed the stem and took a photo of the pipe to have a look at the parts and overall look.

I took a photo of the stamping on the underside of the shank. It is clear and readable as noted above. I removed the stem and took a photo of the pipe to have a look at the parts and overall look. I started my work on the pipe by cleaning up the darkening on the inner edge of the bowl and the spots on the rim top. I used a folded piece of 220 grit sandpaper to smooth and shape them. It looked much better.

I started my work on the pipe by cleaning up the darkening on the inner edge of the bowl and the spots on the rim top. I used a folded piece of 220 grit sandpaper to smooth and shape them. It looked much better. I sanded the bowl with 320-3500 grit sanding pads. I wiped the bowl down with a damp cloth after each sanding pad to remove the sanding debris. It began to really take on a shine.

I sanded the bowl with 320-3500 grit sanding pads. I wiped the bowl down with a damp cloth after each sanding pad to remove the sanding debris. It began to really take on a shine.

I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped the bowl down with a damp cloth after each sanding pad. The grain really began to sing.

I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped the bowl down with a damp cloth after each sanding pad. The grain really began to sing.

I worked some Before & After Restoration Balm into the surface of the briar with my fingertips to clean, enliven and protect the briar. II worked it in to the plateau shank end with a shoe brush. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

I worked some Before & After Restoration Balm into the surface of the briar with my fingertips to clean, enliven and protect the briar. II worked it in to the plateau shank end with a shoe brush. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

I set the bowl aside and turned my attention to the stem. I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine. I gave it another coat of Obsidian Oil.

I set the bowl aside and turned my attention to the stem. I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine. I gave it another coat of Obsidian Oil.

I am excited to finish this early Rad Davis Hand Made Freehand Apple. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I hand buffed the pipe with a clean buffing pad to raise the shine. It is fun to see what the polished bowl looks like with beautiful mixed grain all around it, looks great with the polished black vulcanite stem. This smooth Rad Davis Freehand Apple is great looking and the pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 6 inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 54 grams/1.90 ounces. It turned out to be a beautiful pipe. I will be putting on the rebornpipes store in the American (US) Pipe Makers Section. Let me know if you are interested in adding it to your collection. Thanks for your time as I walked through the restoration.

I am excited to finish this early Rad Davis Hand Made Freehand Apple. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I hand buffed the pipe with a clean buffing pad to raise the shine. It is fun to see what the polished bowl looks like with beautiful mixed grain all around it, looks great with the polished black vulcanite stem. This smooth Rad Davis Freehand Apple is great looking and the pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 6 inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 54 grams/1.90 ounces. It turned out to be a beautiful pipe. I will be putting on the rebornpipes store in the American (US) Pipe Makers Section. Let me know if you are interested in adding it to your collection. Thanks for your time as I walked through the restoration.