by Steve Laug

We received the next pipe from our source in Copenhagen, Denmark on 11/21/2023. It is another fitting New Year’s Day restoration. It is a Peterson’s 301 Bent Pot. It is stamped on the underside of the shank and reads Peterson’s [arched over] System [over] Standard next that is stamped Made in the Republic of Ireland (in three lines) [over] the shape number 301. The nickel ferrule on the shank is stamped K&P [over] Petersons. The pipe is dirty, obviously another favourite smoker. There is grime ground into the finish. There is a thick cake in the bowl and a light overflow of lava on the inner edge and the sandblast rim top. The nickel ferrule is lightly tarnished. The stem is dirty, but is shiny and well cared for. Jeff took photos of it before he started his clean up work. I have included those below.  Jeff took photos of the rim top and stem to show the general condition of the pipe. The bowl is heavily caked and there was some darkening and a lava overflow on the sandblast rim top and the inner edge. The stem looks amazingly good for a pipe of this age.

Jeff took photos of the rim top and stem to show the general condition of the pipe. The bowl is heavily caked and there was some darkening and a lava overflow on the sandblast rim top and the inner edge. The stem looks amazingly good for a pipe of this age.

Jeff took photos of the bowl sides and heel to show the look of the sandblast that was around this bowl. The blast really highlights the grain underneath and is quite beautiful around the sides of the bowl and shank. It is another nice looking pipe.

Jeff took photos of the bowl sides and heel to show the look of the sandblast that was around this bowl. The blast really highlights the grain underneath and is quite beautiful around the sides of the bowl and shank. It is another nice looking pipe.

He took photos of underside of the shank to show the stamping. The stamping is clear and readable in the photos below and is as noted above. The stamping on the nickel ferrule is clear and readable as noted above.

He took photos of underside of the shank to show the stamping. The stamping is clear and readable in the photos below and is as noted above. The stamping on the nickel ferrule is clear and readable as noted above.

I am including the link to the Pipedia’s article on Peterson pipes. It is a great read in terms of the history of the brand (https://pipedia.org/wiki/Peterson).

I am including the link to the Pipedia’s article on Peterson pipes. It is a great read in terms of the history of the brand (https://pipedia.org/wiki/Peterson).

I turned to “The Peterson Pipe” by Mark Irwin and Gary Malmberg to get some background on the Peterson’s System Line. On page 314 it had the following information.

Peterson’s over System – Pipes stamped Peterson’s System have been documented as early as 1920. A ’20 brochure is the earliest printed reference to the Peterson System. The pipe came in three quality grades (no mark, 2, or 3) until 1959, thereafter as De Luxe (no mark), Premier (the old 2) and Standard (the old 3).

Peterson’s over System over Standard (c1945-)

I learned previously that the shape 301 was not introduced until 1975. Considering the Republic stamp, this one would likely date between 1975 and 2000. My guess is that the pipe was made somewhere between 1975 and mid-80s. Now it was time to work on the pipe.

With that information at hand I turned to work on the pipe itself. Jeff had thoroughly cleaned up the pipe. He reamed the pipe with a PipNet Pipe Reamer and cleaned up the remnants with a Savinelli Fitsall Pipe Knife. He scrubbed the bowl with undiluted Murphy’s Oil Soap with a tooth brush. He rinsed it under running warm water to remove the soap and grime. He cleaned out the inside of the shank and the airway in the stem with alcohol, cotton swabs and pipe cleaners. He scrubbed the exterior of the stem with Soft Scrub to remove as much of the oxidation and calcification as possible. He soaked the stem in Before & After Deoxidizer and rinsed it off with warm water. I took photos of the pipe before I started to work on it.

I took close up photos of the bowl and the stem. You can see the reamed bowl and the clean rim top and edges. It looks good. The stem surface was clean but there are light tooth marks and chatter on both sides on and ahead of the button.

I took close up photos of the bowl and the stem. You can see the reamed bowl and the clean rim top and edges. It looks good. The stem surface was clean but there are light tooth marks and chatter on both sides on and ahead of the button. I took a photo of the stamping on the underside of the shank. It is faint in spots but readable as noted above. I removed the stem from the shank and took a photo to give a sense of the proportions of the pipe. It is really quite nice looking.

I took a photo of the stamping on the underside of the shank. It is faint in spots but readable as noted above. I removed the stem from the shank and took a photo to give a sense of the proportions of the pipe. It is really quite nice looking. The briar was in such good condition that I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips and a shoebrush to clean, enliven and protect the briar. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine.

The briar was in such good condition that I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips and a shoebrush to clean, enliven and protect the briar. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine.

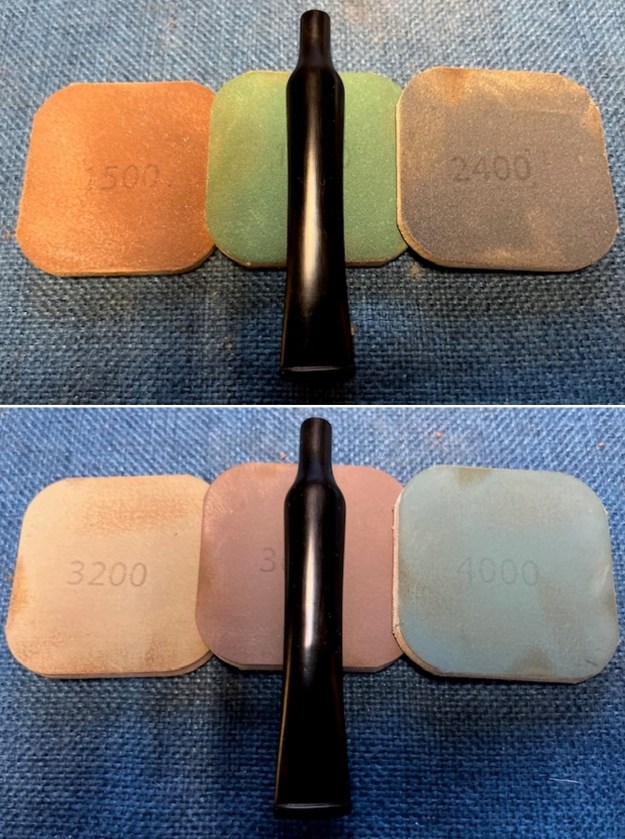

I sanded the stem with 320-3500 grit sanding pads and wiped it down with a cloth and Obsidian Oil to remove the debris. It began to take on a rich shine.

I sanded the stem with 320-3500 grit sanding pads and wiped it down with a cloth and Obsidian Oil to remove the debris. It began to take on a rich shine. I polished the vulcanite stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with a damp cloth after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

I polished the vulcanite stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with a damp cloth after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

This nice looking Peterson’s System Standard 301 Sandblast Bent Pot with a classic Peterson’s P-lip vulcanite stem looks much better now that it has been restored. The rim top and edges cleaned up very well. The dark brown stains on the bowl came alive with the polishing and waxing. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Peterson’s System Standard is a beauty and fits nicely in the hand and looks very good. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ½ inch, Chamber diameter: ¾ of an inch. The weight of the pipe is 45 grams/1.62 ounces. I will be putting it in the rebornpipes store in the Irish Pipemakers Section soon. If you are interested in adding this pipe to your collection send me a message or an email. Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!

This nice looking Peterson’s System Standard 301 Sandblast Bent Pot with a classic Peterson’s P-lip vulcanite stem looks much better now that it has been restored. The rim top and edges cleaned up very well. The dark brown stains on the bowl came alive with the polishing and waxing. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Peterson’s System Standard is a beauty and fits nicely in the hand and looks very good. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ½ inch, Chamber diameter: ¾ of an inch. The weight of the pipe is 45 grams/1.62 ounces. I will be putting it in the rebornpipes store in the Irish Pipemakers Section soon. If you are interested in adding this pipe to your collection send me a message or an email. Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!