By Steve Laug

When I sent back his pipes, Sonny in Salmon Arm, BC contacted me and said he had four more he wanted me to work on. He put them in the mail and I received them on Monday this week. I took a photo of the box of four pipes once I unwrapped them. There were 4 interesting and very unique pipes – a Vauen Solitaire 148 Freehand Filter Pipe that is huge, an older case meerschaum with an overclocked stem, a Dunhill Wanghee Sandblast Dublin with a Bamboo shank and short saddle stem and finally an Anima wax drip sand blast Billiard carved by Brian McNulty. All needed varying degrees of restoration. I chose to work on the big Vauen Solitaire Freehand. It is stamped on the left side and reads Solitaire. On the left side it is stamped Vauen and on the underside it is stamped with the shape number 148 followed by a pair of crossed bent pipes. The finish was shiny but there was also a dullness to the amazing grain around the bowl. There were some small nicks on the bowl where it looked like it had been dropped. A moderate cake in the bowl was in the bowl and some light lava on the rim top and some darkening on the inner edge. The fancy filter saddle stem was lightly oxidized and there was tooth marks and chatter ahead of the button. The top of the saddle also bore the Vauen white dot. I took these photos before I started my work on the pipe.

I chose to work on the big Vauen Solitaire Freehand. It is stamped on the left side and reads Solitaire. On the left side it is stamped Vauen and on the underside it is stamped with the shape number 148 followed by a pair of crossed bent pipes. The finish was shiny but there was also a dullness to the amazing grain around the bowl. There were some small nicks on the bowl where it looked like it had been dropped. A moderate cake in the bowl was in the bowl and some light lava on the rim top and some darkening on the inner edge. The fancy filter saddle stem was lightly oxidized and there was tooth marks and chatter ahead of the button. The top of the saddle also bore the Vauen white dot. I took these photos before I started my work on the pipe.

I took a photo of the rim top and bowl to show the condition of both of them. There is a moderate cake in the bowl. The plateau rim top has some lava and rim darkening around the top and inner edge. The plateau on the shank end is dusty as well. The photos of the stem show the oxidation, stickiness from a price tag and some light tooth marks/chatter on both sides ahead of the button.

I took a photo of the rim top and bowl to show the condition of both of them. There is a moderate cake in the bowl. The plateau rim top has some lava and rim darkening around the top and inner edge. The plateau on the shank end is dusty as well. The photos of the stem show the oxidation, stickiness from a price tag and some light tooth marks/chatter on both sides ahead of the button. I took photos of the stamping on the sides of the shank. The stamping was clear and readable as noted above. I removed the stem from the shank and took a photo to show the beauty of the pipe.

I took photos of the stamping on the sides of the shank. The stamping was clear and readable as noted above. I removed the stem from the shank and took a photo to show the beauty of the pipe.

Once again, I am including the background on the Vauen brand that I have used before. I think it is an important part of the restoration process for me. I always read over it before I start my work on a pipe. It always personalizes and adds colour to the pipe I am working on. As usual, I turned to Pipephil’s site (http://pipephil.eu/logos/en/logo-v1.html). I did a screen capture of the information on the site. There was a great sidebar that gave some history of the brand. I include both of them below.

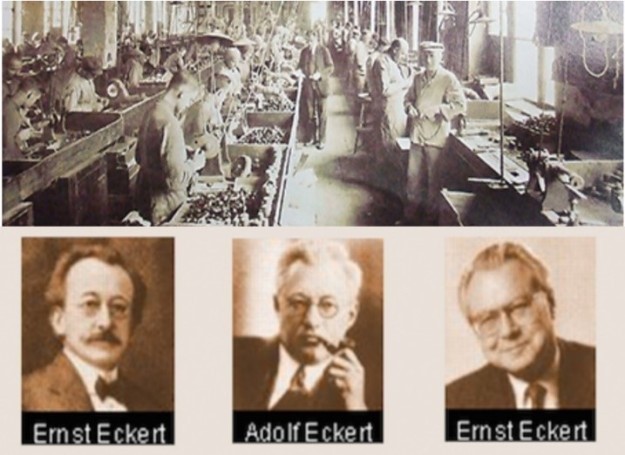

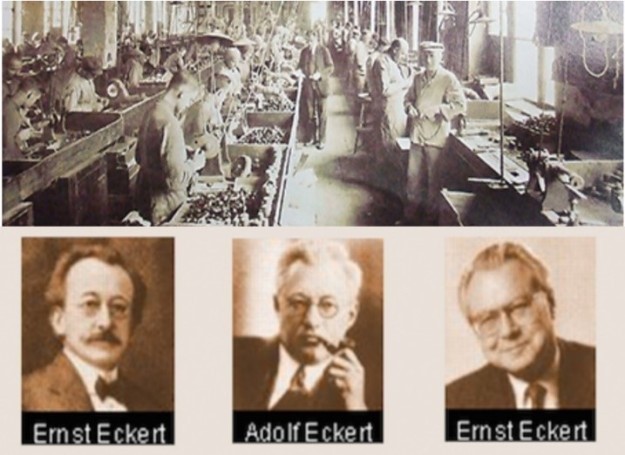

Once again, I am including the background on the Vauen brand that I have used before. I think it is an important part of the restoration process for me. I always read over it before I start my work on a pipe. It always personalizes and adds colour to the pipe I am working on. As usual, I turned to Pipephil’s site (http://pipephil.eu/logos/en/logo-v1.html). I did a screen capture of the information on the site. There was a great sidebar that gave some history of the brand. I include both of them below.  In 1848, Karl Ellenberger and his partner Carl August Ziener establish a pipe factory in Nuremberg. In 1901 they merge with Gebhard Ott an other factory in town and they create a firm named Vereinigten Pfeifenfabriken Nürnberg (abbreviated : VPFN*). Shortly after Ernst Eckert, a member of the Ott family became manager of the society. During the 20th century Adolf, Ernst (jr) and Alexander Eckert (CEO in 2012) followed one another at Vauen’s head.* VPFN : “V” is said VAU in German (pronounce faou) and “N” becomes EN. Hence VAUEN.

In 1848, Karl Ellenberger and his partner Carl August Ziener establish a pipe factory in Nuremberg. In 1901 they merge with Gebhard Ott an other factory in town and they create a firm named Vereinigten Pfeifenfabriken Nürnberg (abbreviated : VPFN*). Shortly after Ernst Eckert, a member of the Ott family became manager of the society. During the 20th century Adolf, Ernst (jr) and Alexander Eckert (CEO in 2012) followed one another at Vauen’s head.* VPFN : “V” is said VAU in German (pronounce faou) and “N” becomes EN. Hence VAUEN.

Dal Stanton (Pipesteward.com) wrote a great piece on the history of the brand on a Vauen pipe that he worked on. I reread that and quote a section from the blog below that gives a great sense of the story of this interesting German brand and some photos from the website (https://rebornpipes.com/2021/04/27/breathing-new-life-into-a-german-vauen-6294-p-lip-saddle-billiard-for-a-special-young-lady/).

… I turn to the question of the history of the VAUEN name? I look to the History section of the VAUEN website and again, I am impressed with the presentation. Whenever I work on a pipe, and especially when a pipe name is new to me, I enjoy looking at its history to appreciate the pipe more fully now on my worktable. From VAUEN’s website: Quality and a wealth of ideas have a long tradition at VAUEN. 160 years of VAUEN: that means 160 years of skilled workmanship and modern technology and 160 years of experience in fulfilling the individual wishes of today’s pipe lovers, and those of tomorrow.

Quality and a wealth of ideas have a long tradition at VAUEN. 160 years of VAUEN: that means 160 years of skilled workmanship and modern technology and 160 years of experience in fulfilling the individual wishes of today’s pipe lovers, and those of tomorrow.

In Nuremberg in 1848, Karl Ellenberger and his partner Carl August Ziener turned an idea into reality: Germany’s first pipe manufacturer produced tobacco pipes for connoisseurs around the world using a selection of the best wood. In an amalgamation with the Gebhard Ott pipe factory, which was founded in 1866 in Nuremberg, the Vereinigten Pfeifenfabriken Nuremberg (United Pipe Factories Nuremberg, or VPFN) was born in 1901. Under the management of Ernst Eckert, a descendent of the founding Ott family, a company was born whose products and services would shape the tobacco and smoking culture in Europe and overseas for the next 160 years and counting.

The question about the name, VAUEN, not being a name of a person and why it is capitalized throughout is explained:

In his search for a name that would be easily remembered by all pipe lovers, Ernst Eckert’s son, Adolf Eckert, coined a new name for the company in 1909: VAUEN – a composition of the first letters V (pronounced vow) of Vereinigte Pfeifenfabriken and N (pronounced en) of Nuremberg. A brand for the future was born.

Reminded once again of the colours of the brand, I turned my attention to the pipe itself. I wiped the bowl down with some acetone on cotton pads to remove the shiny coat on the bowl and the plateau on the rim top and shank end. It came out looking better.

I reamed the bowl with a PipNet reamer using the second and third cutting head to remove the cake. I cleaned up what remained of the cake with a Savinelli Fitsall Pipe Knife. I sanded the walls of the bowl to remove any remnants with 220 grit sandpaper wrapped around a piece of dowel. Once finished the inside of the bowl was smooth and the briar was bare.

I reamed the bowl with a PipNet reamer using the second and third cutting head to remove the cake. I cleaned up what remained of the cake with a Savinelli Fitsall Pipe Knife. I sanded the walls of the bowl to remove any remnants with 220 grit sandpaper wrapped around a piece of dowel. Once finished the inside of the bowl was smooth and the briar was bare.

Once the pipe was reamed and the rim top cleaned I worked on the internals – the mortise and airway in the shank and airway in the stem. It appeared that this pipe has been smoked with the filter so the inside of the shank was not as bad as I expected. The stem was more of the same. I cleaned them both with pipe cleaners, cotton swabs and alcohol and the results are very good.

Once the pipe was reamed and the rim top cleaned I worked on the internals – the mortise and airway in the shank and airway in the stem. It appeared that this pipe has been smoked with the filter so the inside of the shank was not as bad as I expected. The stem was more of the same. I cleaned them both with pipe cleaners, cotton swabs and alcohol and the results are very good. I scrubbed the externals of the bowl with undiluted Murphy’s Oil Soap and a tooth brush. I worked over the plateau portions on the rim top and shank end with the soap and brush. I rinsed off the grime and grit from the cleaning with warm water and dried it with a soft cloth. It looked much better without the grime.

I scrubbed the externals of the bowl with undiluted Murphy’s Oil Soap and a tooth brush. I worked over the plateau portions on the rim top and shank end with the soap and brush. I rinsed off the grime and grit from the cleaning with warm water and dried it with a soft cloth. It looked much better without the grime.

I polished the briar by dry sanding with 1500-12000 grit micromesh sanding pads. I wiped the briar down with a damp cloth after each sanding pad. By the last three pads the briar really took on a rich shine.

I polished the briar by dry sanding with 1500-12000 grit micromesh sanding pads. I wiped the briar down with a damp cloth after each sanding pad. By the last three pads the briar really took on a rich shine.

When I get the bowl to this point in the process I use Before & After Restoration Balm. It is a paste/balm that works to deep clean the finish, enliven and protect the briar. I work it into the briar with my finger tips to make sure that it covers every square inch of the pipe. I used a shoe brush on the plateau to get the product into the grooves. I set it aside for 10 minutes to let it do its work. Once the time has passed I wiped it off with a soft cloth then buffed it with a cotton cloth. The briar really began to have a deep shine. The photos I took of the bowl at this point mark the progress in the restoration.

When I get the bowl to this point in the process I use Before & After Restoration Balm. It is a paste/balm that works to deep clean the finish, enliven and protect the briar. I work it into the briar with my finger tips to make sure that it covers every square inch of the pipe. I used a shoe brush on the plateau to get the product into the grooves. I set it aside for 10 minutes to let it do its work. Once the time has passed I wiped it off with a soft cloth then buffed it with a cotton cloth. The briar really began to have a deep shine. The photos I took of the bowl at this point mark the progress in the restoration.

I set the bowl aside and turned my attention to the stem. I scrubbed the oxidized surface with cotton pads and Soft Scrub and was able to remove the majority of the oxidation on the vulcanite.

I set the bowl aside and turned my attention to the stem. I scrubbed the oxidized surface with cotton pads and Soft Scrub and was able to remove the majority of the oxidation on the vulcanite. I sanded the stem with 320-3500 grit sanding pads to break up the remaining oxidation. I wiped it down after each sanding pad with an Obsidian Oil impregnated cloth. It began to look good.

I sanded the stem with 320-3500 grit sanding pads to break up the remaining oxidation. I wiped it down after each sanding pad with an Obsidian Oil impregnated cloth. It began to look good. I took out my box of Vauen 9mm filters and put a new filter in the tenon of the stem. It fit perfectly and sat in the stem and shank as expected. I also found a new adapter that converts the tenon from a 9mm to a regular non-filter pipe.

I took out my box of Vauen 9mm filters and put a new filter in the tenon of the stem. It fit perfectly and sat in the stem and shank as expected. I also found a new adapter that converts the tenon from a 9mm to a regular non-filter pipe. I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the stem down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine. Once I had finished the polishing I gave it final coat of Obsidian Oil and set it aside to dry.

I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the stem down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine. Once I had finished the polishing I gave it final coat of Obsidian Oil and set it aside to dry.

As usual at this point in the restoration process I am excited to be on the homestretch. I look forward to the final look when I put a pipe back together, polished and waxed. I polished the bowl and stem on the Vauen Solitaire 148 Freehand with Blue Diamond to polish out the scratches in the briar and the vulcanite. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The grain really pops with the wax and polish. The shiny black vulcanite stem is a beautiful contrast to the browns of the bowl and shank. This Vauen Solitair 148 Saddle Stem Freehand was another fun pipe to work on. The pipe is comfortable pipe to hold in the hand. The finished pipe is shown in the photos below. The dimensions of the pipe are Length: 7 inches, Height: 3 inches, Outside diameter of the bowl: 1 3/4 inches x 1 1/4 inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 3.46 ounces/98 grams. Four more of Sonny’s pipes to work on before I send them all back to him. Thanks for reading this blog and my reflections on the pipe while I working on it. As always, I encourage your questions and comments as you read the blog. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipemen and women who hold our pipes in trust until they pass on into the trust of those who follow us.

As usual at this point in the restoration process I am excited to be on the homestretch. I look forward to the final look when I put a pipe back together, polished and waxed. I polished the bowl and stem on the Vauen Solitaire 148 Freehand with Blue Diamond to polish out the scratches in the briar and the vulcanite. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The grain really pops with the wax and polish. The shiny black vulcanite stem is a beautiful contrast to the browns of the bowl and shank. This Vauen Solitair 148 Saddle Stem Freehand was another fun pipe to work on. The pipe is comfortable pipe to hold in the hand. The finished pipe is shown in the photos below. The dimensions of the pipe are Length: 7 inches, Height: 3 inches, Outside diameter of the bowl: 1 3/4 inches x 1 1/4 inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 3.46 ounces/98 grams. Four more of Sonny’s pipes to work on before I send them all back to him. Thanks for reading this blog and my reflections on the pipe while I working on it. As always, I encourage your questions and comments as you read the blog. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipemen and women who hold our pipes in trust until they pass on into the trust of those who follow us.