Blog by Steve Laug

The next pipe on the table is one of those “accidental” pickups that happen when you do this kind of restoration work. I was in communication with a lady in another part of British Columbia about repairing a pipe she had picked up in her journeys. She wanted to know if it was repairable and what I would charge for a repair and restoration. I asked her about the brand and the condition of the pipe and what the nature of the repairs would be. She told me the pipe was a Brigham and that it was covered in nicks and chips around the bowl, rim top and shank. She said it was heavily marked. I asked her to send me some photos of the pipe so I could see what needed to be done. She had not exaggerated on the chips, it reminded me of a pipe I had worked on that someone’s dog had gotten a hold of and gnawed to its current condition. I sent her a price on the restoration of the bowl and the removal of the oxidation on the stem surface. She thought about it and decided to pass and dispose of the pipe. I had a brain storm and offered to buy it from her for what she had paid and the postage to send it to me. We struck a deal and she put it in the mail to me. I received it earlier this week.

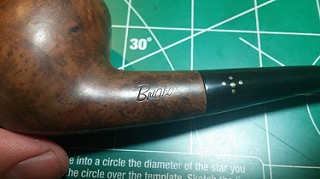

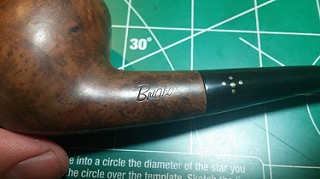

I opened the package and took the pipe out of the package. The pipe was a rusticated ¼ bent acorn with a black vulcanite stem. The stamping on the underside of the shank has the shape number 241 on the underside of the shank followed by Brigham in script. The vulcanite stem has a two brass dots inserted on the left side. Other than the gnawing on the rustication – heavier on the right side than the left and marks on the rim top it was nice looking pipe. The big surprise for me was that the pipe had not been smoked. The bowl was clean and had a light coat of stain and the tenon had a brand new Brigham Distillator Hard Maple Filter. The ¼ bent vulcanite stem works very well with the bowl. It is light weight and comfortable pipe to hold. To summarize what I saw – this Brigham Canada 241 Acorn is a well made pipe. The bowl and shank show the gnaw marks on the sides of both and the rim top. The stem was oxidized more heavily on the top than the underside and there were marks left behind by glue from price stickers. The look and feel of the pipe in the hand is great. It will be an interesting pipe to work on. I took photos of it before I started my work.

I opened the package and took the pipe out of the package. The pipe was a rusticated ¼ bent acorn with a black vulcanite stem. The stamping on the underside of the shank has the shape number 241 on the underside of the shank followed by Brigham in script. The vulcanite stem has a two brass dots inserted on the left side. Other than the gnawing on the rustication – heavier on the right side than the left and marks on the rim top it was nice looking pipe. The big surprise for me was that the pipe had not been smoked. The bowl was clean and had a light coat of stain and the tenon had a brand new Brigham Distillator Hard Maple Filter. The ¼ bent vulcanite stem works very well with the bowl. It is light weight and comfortable pipe to hold. To summarize what I saw – this Brigham Canada 241 Acorn is a well made pipe. The bowl and shank show the gnaw marks on the sides of both and the rim top. The stem was oxidized more heavily on the top than the underside and there were marks left behind by glue from price stickers. The look and feel of the pipe in the hand is great. It will be an interesting pipe to work on. I took photos of it before I started my work.

I took close up photos so that I could have a clearer picture of the condition of the bowl, rim edges and top. The rim top photos confirm my assessment above. The bowl is unsmoked and there are scratches and nicks in surface. On the left and right sides there are nicks in the outer edge. The inner edge is in excellent condition. The stem is oxidized – more heavily on the topside than the underside, which suggested that it had been sitting in the sun. There were no tooth marks or chatter on the surface. There was also some sticky substance left behind by a price tag on the underside.

I took close up photos so that I could have a clearer picture of the condition of the bowl, rim edges and top. The rim top photos confirm my assessment above. The bowl is unsmoked and there are scratches and nicks in surface. On the left and right sides there are nicks in the outer edge. The inner edge is in excellent condition. The stem is oxidized – more heavily on the topside than the underside, which suggested that it had been sitting in the sun. There were no tooth marks or chatter on the surface. There was also some sticky substance left behind by a price tag on the underside. I took photos of the stamping on the underside of the shank. On the underside of the shank it is stamped with the shape number 241. That is followed by Brigham in script. The vulcanite stem has two brass pins in the left side of the taper. The stamping is faint around the shape number and a little blurred. There is no Canada stamp under the Brigham.

I took photos of the stamping on the underside of the shank. On the underside of the shank it is stamped with the shape number 241. That is followed by Brigham in script. The vulcanite stem has two brass pins in the left side of the taper. The stamping is faint around the shape number and a little blurred. There is no Canada stamp under the Brigham. I am also including the information from Pipedia’s article on Brigham pipes. It is a great read in terms of the history of the brand (https://pipedia.org/wiki/Brigham_Pipes). Charles Lemon (Dadspipes) is currently working on a book on the history of the brand. Even though the book is written I still use this material for a quick overview.

I am also including the information from Pipedia’s article on Brigham pipes. It is a great read in terms of the history of the brand (https://pipedia.org/wiki/Brigham_Pipes). Charles Lemon (Dadspipes) is currently working on a book on the history of the brand. Even though the book is written I still use this material for a quick overview.

Roy Brigham, after serving an apprenticeship under an Austrian pipesmith, started his own pipe repair shop in Toronto, in 1906. By 1918 the business had grown to include five other craftsmen and had developed a reputation across Canada for the high quality of workmanship. After repairing many different brands of pipes over the years, Roy noted certain recurring complaints by pipe smokers, the most common referred to as “tongue bite”. Tongue bite is a burning sensation on the smoker’s tongue, previously thought to be due to the heat of the smoke (i.e. a “hot smoking pipe”).

He soon began manufacturing his own pipes, which were lightweight, yet featured a more rugged construction, strengthening the weak points observed in other pipes. The problem of tongue bite intrigued him, and he decided to make overcoming it a future goal.

About 1938, Roy’s son Herb joined him to assist in the business. The business barely survived the great depression because pipes were considered to be a luxury, not a necessity, and selling pipes was difficult indeed. In approximately 1937 [1], after some experimentation, Roy and Herb discovered that tongue bite was in fact a form of mild chemical burn to the tongue, caused by tars and acids in the smoke. They found that by filtering the smoke, it was possible to retain the flavour of the tobacco and yet remove these impurities and thereby stop the tongue bite.

Just as Thomas Edison had searched far and wide for the perfect material from which to make the first electric light bulb filaments, Roy & Herb began experimenting with many materials, both common and exotic, in the quest for the perfect pipe filter. Results varied wildly. Most of the materials didn’t work at all and some actually imparted their own flavour into the smoke. They eventually found just two materials that were satisfactory in pipes: bamboo and rock maple. As bamboo was obviously not as readily available, rock maple then became the logical choice.

They were able to manufacture a replaceable hollow wooden tube made from rock maple dowelling, which when inserted into a specially made pipe, caused absolutely no restriction to the draw of the pipe, yet extracted many of the impurities which had caused tongue bite. The result was indeed a truly better smoking pipe…

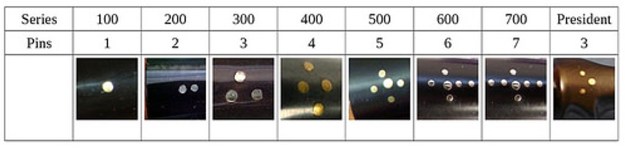

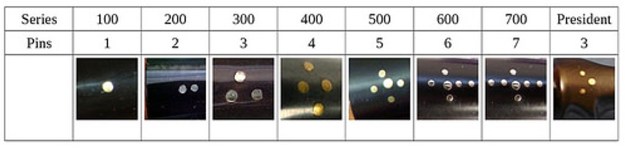

I then turned to a second article by Charles Lemon called, “A Closer Look at the Dots, Dates, and Markings of Brigham Pipes” to be able to pin down the time frame that the pipe was made in and to help interpret the stampings and shape number on the pipe. Here is the link to his article (https://pipedia.org/wiki/Brigham_Pipes_%E2%80%93_A_Closer_Look_at_Dots,_Dates_and_Markings).

I have dubbed the decades between 1980 and 2000 the Late Canadian Era, a period that saw several changes at Brigham that are of note to the collector. First, the traditional 8-grade pinning system (the famous Brigham “Dots” which denoted the quality of the pipe) was changed to a 7-grade system to simplify pinning (more on this below), and the Norsemen and Valhalla series were merged to form the President Series, which represented the very finest pipes coming out of the Toronto factory. Early pipes from this era (left, below) are stamped with a shape number and “Brigham” over “Canada”; later pipes (late 1980s+, on right below) are stamped simply with a shape number and the Brigham logo.

I have dubbed the decades between 1980 and 2000 the Late Canadian Era, a period that saw several changes at Brigham that are of note to the collector. First, the traditional 8-grade pinning system (the famous Brigham “Dots” which denoted the quality of the pipe) was changed to a 7-grade system to simplify pinning (more on this below), and the Norsemen and Valhalla series were merged to form the President Series, which represented the very finest pipes coming out of the Toronto factory. Early pipes from this era (left, below) are stamped with a shape number and “Brigham” over “Canada”; later pipes (late 1980s+, on right below) are stamped simply with a shape number and the Brigham logo.

I read further in the article to the section entitled Revised Dot System 1980. I quote from that below.

Brigham changed the Dot system in 1980, adding a 7 Dot at the top of the line, dropping the names of each series and eliminating the confusing vertical and horizontal 3 Dot configurations. The Norsemen and Valhalla series were combined to form the President series of freehand pipes, which adopted a 3 Dot pattern with a larger dot on the right as shown below. The 7- grade pinning system stayed in place from 1980 to 2001.  With the information from article and the chart above I knew what I was dealing with in terms of the stamping and the age of this pipe. I learned that this Late Canadian Era was made between 1980-2000. The pipe is a Brigham (2-Dot) 241 Acorn. The stamping pins it down to 1990 and following. Now it was time to work on the pipe.

With the information from article and the chart above I knew what I was dealing with in terms of the stamping and the age of this pipe. I learned that this Late Canadian Era was made between 1980-2000. The pipe is a Brigham (2-Dot) 241 Acorn. The stamping pins it down to 1990 and following. Now it was time to work on the pipe.

I took of the photo of the most damaged portion of the bowl side – the right side. You can see the deep nicks and gouges on surface of the bowl. These would be the first things that I would address. I stained the spots on the bowl with a Mahogany stain pen to blend them into the surrounding rustication around the bowl. Once stained it looked much better.

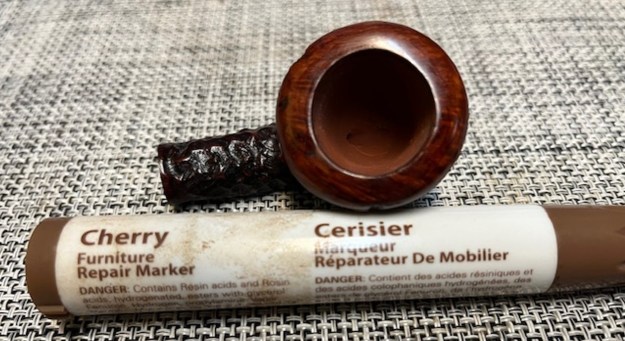

Next turned to deal with the rim top. I wiped it down with a cotton pad and alcohol to remove the fragments of the finish and clean out the debris in the gouges along the outer edge of the bowl. I sanded the rim top with the 500-1500 grit sanding pads to smooth it out. I polished it with micromesh sanding pads – dry sanding it with 1200-15000 grit pads. I wiped the bowl down with a damp cloth after each sanding pad. The grain really started to rise to the surface as I polished it.

Next turned to deal with the rim top. I wiped it down with a cotton pad and alcohol to remove the fragments of the finish and clean out the debris in the gouges along the outer edge of the bowl. I sanded the rim top with the 500-1500 grit sanding pads to smooth it out. I polished it with micromesh sanding pads – dry sanding it with 1200-15000 grit pads. I wiped the bowl down with a damp cloth after each sanding pad. The grain really started to rise to the surface as I polished it.

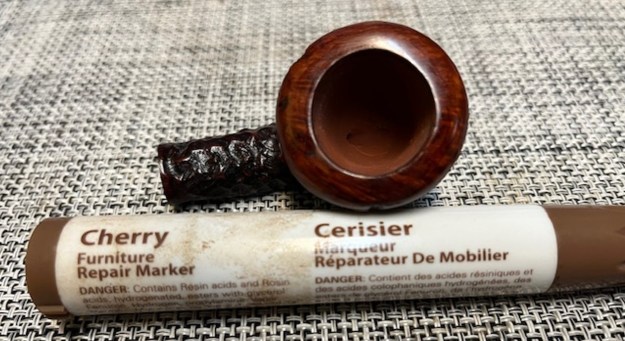

I used a Cherry Stain Pen to touch up the rim top and blend it into the surrounding stain around the bowl rustication. It looked amazingly good.

I used a Cherry Stain Pen to touch up the rim top and blend it into the surrounding stain around the bowl rustication. It looked amazingly good. I rubbed the bowl and shank down with Before & After Restoration Balm to deep clean the finish on the bowl and shank. The product works to clean, enliven and protect the briar. I worked it in with my fingers to get it into the briar. I used a horsehair shoe brush to work it into the sand blast. I let it sit for 10 minutes then I wiped it off and buffed it with a soft cloth. The briar really began to have a rich shine. I took some photos of the bowl at this point to mark the progress in the restoration. It is a beautiful bowl.

I rubbed the bowl and shank down with Before & After Restoration Balm to deep clean the finish on the bowl and shank. The product works to clean, enliven and protect the briar. I worked it in with my fingers to get it into the briar. I used a horsehair shoe brush to work it into the sand blast. I let it sit for 10 minutes then I wiped it off and buffed it with a soft cloth. The briar really began to have a rich shine. I took some photos of the bowl at this point to mark the progress in the restoration. It is a beautiful bowl.

I set the bowl aside and turned my attention to the stem. I sanded the surface of the vulcanite with the 2 inch sanding pads – 320-3500 grit pads. I dry sanded the surface until I have removed all of the oxidation and the stem started to really shine.

I set the bowl aside and turned my attention to the stem. I sanded the surface of the vulcanite with the 2 inch sanding pads – 320-3500 grit pads. I dry sanded the surface until I have removed all of the oxidation and the stem started to really shine. I refit the aluminum tenon with the Brigham Hard Rock Maple Filter Distillator. It is a unique and cool smoking experience.

I refit the aluminum tenon with the Brigham Hard Rock Maple Filter Distillator. It is a unique and cool smoking experience. I polished light tooth marks and chatter out of the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the stem down after each sanding pad with Obsidian Oil.

I polished light tooth marks and chatter out of the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the stem down after each sanding pad with Obsidian Oil.

I polished the stem with Before & After Pipe Stem Polish – both Fine and Extra Fine. I gave it a coat of Obsidian Pipe Stem Oil. It works to protect the stem from oxidizing. I set it aside to dry.

I polished the stem with Before & After Pipe Stem Polish – both Fine and Extra Fine. I gave it a coat of Obsidian Pipe Stem Oil. It works to protect the stem from oxidizing. I set it aside to dry.  The final steps in my process involve using the buffer. I buffed the bowl and stem with Blue Diamond to polish out the light scratches in the briar and the vulcanite. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax. I have found that I can get a deeper shine if I follow up the wax buff with a buff with a clean buffing pad. It works to raise the shine and then I hand buff with a microfiber cloth to deepen the shine. It is always fun for me to see what the polished bowl looks like with the polished stem. It really is a nice pipe. The rusticated finish around the bowl sides and shank looks great with the vulcanite stem. The Brigham Canada Acorn 241 feels great in my hand. It is a well balanced pipe. Have a look at it with the photos below. The dimensions are Length: 5 ¾ inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 3/8 inches, Chamber diameter: 7/8 of an inch. The weight of the pipe is 1.20 ounces/34 grams. It is a beautiful pipe that I will soon be adding to the rebornpipes store in the Canadian Pipemakers Section. If you would like to add it to your collection let me know. It should be a great smoking pipe.

The final steps in my process involve using the buffer. I buffed the bowl and stem with Blue Diamond to polish out the light scratches in the briar and the vulcanite. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax. I have found that I can get a deeper shine if I follow up the wax buff with a buff with a clean buffing pad. It works to raise the shine and then I hand buff with a microfiber cloth to deepen the shine. It is always fun for me to see what the polished bowl looks like with the polished stem. It really is a nice pipe. The rusticated finish around the bowl sides and shank looks great with the vulcanite stem. The Brigham Canada Acorn 241 feels great in my hand. It is a well balanced pipe. Have a look at it with the photos below. The dimensions are Length: 5 ¾ inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 3/8 inches, Chamber diameter: 7/8 of an inch. The weight of the pipe is 1.20 ounces/34 grams. It is a beautiful pipe that I will soon be adding to the rebornpipes store in the Canadian Pipemakers Section. If you would like to add it to your collection let me know. It should be a great smoking pipe.

As always, I encourage your questions and comments as you read the blog. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipe men and women who hold our pipes in trust until they pass on into the trust of those who follow us.