When I saw this old pipe on eBay something about it caught my eye. I could see that it was structurally sound. There were no cracks or significant problems with the bowl or shank. The rim was dirty and the bowl very caked but there did not appear to be any damage to the surface of the rim. The outer edge had been tapped out a few times and showed some minor denting around the bowl. There were some gouges/scratches on the left side of the bowl. It looked as if a sharp instrument had scored the briar. There were some dark stains on the briar that easily could have been burn marks but did not appear to be so from the photos. These stains were on the underside of the shank near the junction of the shank and stem on the left side, on the lower right side of the right side and on the lower left side of the front of the bowl. It looked like stains in the grain rather than burns in the photos so I took a chance on it. The stem looked like it was grey/silver Lucite in the photos and that also intrigued me. The tobacco juices had stained the airway dark. Other than that the stem appeared to be undamaged and would be a pretty easy clean up.

The stamping on the shank was the mystery to me. I had never heard of Harlequin pipes and this one was clearly stamped Harlequin in block letters over Made in England. I wanted to see what I could find out about the brand so I went to my usual sources of information. I checked in “Who made that Pipe” by Wilczak and Colwell and “Pipes Artisans and Trademarks by Lopes to see if either of them identified the maker. Both books had nothing listed for the brand. I went on the British Trademark site and read through many of the listings for Harlequin and found that the name was used by many companies for things from wallpaper to graphics design. There were lines of greeting cards, children’s toys and clothing all bearing that name. I found nothing listed that hinted that the pipes were a registered name. I posted on several online forums that I frequent to see if anyone had any ideas. Several folks on the forums recalled that Gallaher’s Tobacco Limited in Ireland had made a tobacco for years called Harlequin. I did some research to see if they had made pipes.

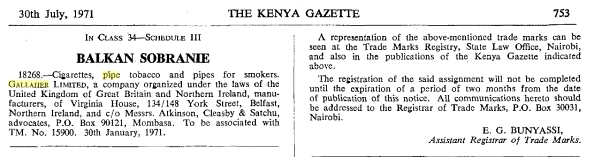

As I dug through various sites on the hunt for information I received some responses on the forums. One person responded that several English tobacco brands also sold pipes – St. Bruno for one did that. Another respondent on Smokers Forums, Chris (flatticus) posted a couple of links to Gallaher’s that confirmed that they had not only made tobacco products but had made pipes or had them made. He included this information:

Ok, so Gallaher’s made at least some pipes into the early 70’s. And according to this link: http://books.google.com/books?id=LAO…20pipe&f=false

They made a Balkan Sobranie pipe. Or at least intended to enough to register the trademark, and along with the trademark for the tobacco itself. Certainly adds a bit of credence to the idea of a tobacco and pipe sharing the same brand name and stamp.

I have included the information cited above from the link to Google books – the Kenya Gazette and have posted it below. In correspondence from E.G. Bunyassi, Assistant Registrar of Trade Marks he clearly states under the heading of Balkan Sobranie that Gallaher’s Limited, a company organized under the laws of the UK of Great Britain and Northern Ireland had made cigarettes, pipe tobacco and pipes.

I asked on the forum whether anyone knew whether the company made pipes. Chris (flatticus) responded again with the following information:

Interesting question, I don’t honestly know, but Gallaher’s used that trademark for like 70 years, and they were a big, big company. Actually from Northern Ireland, and had the biggest tobacco factory in the world in 1896 in Belfast, didn’t completely disappear until they were bought out by Japan Tobacco in 2007, but before that had a distribution conglomerate with RJ Reynolds for their cigarettes and were pretty gigantic. But they didn’t let the Harlequin mark until at least after 1963, when they last registered it. If I had to guess, they probably let it die after 1969 when American Brands, who I think owns Lucky Strike and similar brands, bought them out. They let the mark expire in 1980, but I see no record of anyone else buying it, and apparently it’s still available.

So, blindly guessing, I’d be surprised if anyone had the guts to use the same mark in a same or similar industry other than Gallaher’s. At least not in Ireland or the Commonwealth. But, that said, I can’t find a record or advertisement suggesting they ever made a pipe. However, I did find this thread, containing a quote from Gallaher himself talking about making pipes as a possible future avenue to address the “aging” nature of pipe smokers. http://christianpipesmokers.net/modu…wtopic&t=24081

Perhaps this was part of the “pipe renaissance” project he was talking about, made to get new pipe smokers interested. I checked harlequin ads, there a few vintage ones out there in images, but none of them referenced a pipe, just the tobacco. But the idea of a free pipe with tobacco, or at least a cheap or, as he put it, “disposable” pipe does seem to fit nicely with his intention there. Any way you slice it, though, it’s a nice bit of mystery to ponder. One of my favorite things about estate pipes, hands down.

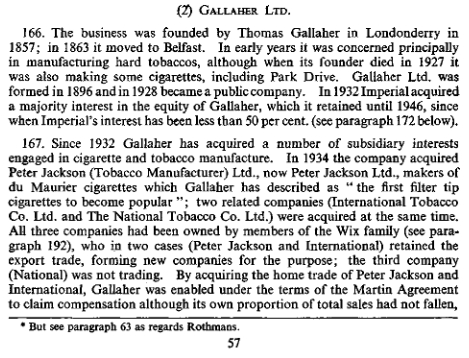

In another link there was information on the Gallaher Company. I copied that information and have posted it below. It makes an interesting read in terms of history of this old brand. I have one chunk of Gallaher’s Irish Roll Cake here that is a good strong smoke. I also have some of their other tobaccos in my cellar but sadly it is no more. I think the likelihood is that the Harlequin pipe was made by them and matched the Harlequin Tobacco blend they sold.

Once the pipe arrived I unpacked it and took it to the work table to begin the clean up. I was surprised that the stem was not grey but in real life almost a light green with heavy black tars in the airway. There were also some tooth marks on the top and bottom of the stem that would need to be repaired. The fit of the stem to the shank was snug and smooth. The bowl was badly caked and the rim covered with thick tar. The bowl had some deep gouges that had appeared in the photos on eBay but they were not as deep as I expected. The grain was far better than I expected. Underneath the dark marks, which appear to be ink stains rather than burn marks was some beautiful cross grain and birdseye as well as mixed grain. It would look beautiful when it was cleaned up and refinished. There were several spots on the briar that had large sticky spots of a glue-like substance.

I reamed the bowl with a PipNet reamer to remove the cake. It was surprisingly soft and crumbly. I took it back to a very thin cake to form the base for a new cake.

I set up a topping board with 220 grit sandpaper to clean off the build up on the rim. It was hard and no matter how hard I scrubbed it, it would not come off. The outer edges of the rim were also damaged from knocking out the bowl after smoking. The light topping would smooth out the edge damage and minimize the effect without changing the look of the bowl.

I scrubbed the exterior of the bowl down with acetone on cotton pads to remove the ink and sticky build up on the finish. I also decided to remove the finish so I scrubbed it until the majority of the finish was gone.

I cleaned the stem with cotton swabs and pipe cleaners and isopropyl alcohol. I was able to scrub out the airway and the slot in the button removing the stains. I also scrubbed the end of the tenon to clean out the staining there. I scrubbed the mortise with alcohol and cotton swabs as well until they came out clean. The internals were cleaned and smelled fresh rather than smelling like old aromatic tobacco.

Once it was clean, I tried to steam out the gouges in the bowl but they would not lift. I could have sanded them out but that would have changed the profile of the bowl so I opted on repairing them with super glue and briar dust.

I sanded the repairs with 220 grit sandpaper and then followed that by sanding with medium and fine grit sanding sponges to blend the surface of the fill with the rest of the surrounding bowl. After sanding the fills I sanded the entire bowl with the medium and fine grit sanding sponge to remove the rest of the finish on the bowl. I carefully worked around the stamping so as not to damage it.

I used clear superglue to repair the deep tooth marks on the top and bottom sides of the stem near the button. The bottom repair can be seen in the photo below. I later sanded it with 220 grit sandpaper and the sanding sponges to blend it into the stem surface.

I decided to use the contrast stain process I have been working on to highlight the grain on this beautiful pipe. I gave it an under coat of black aniline stain. I used a Delrin tenon for a handle in the shank to be able to turn the bowl while I was staining. I applied the stain, flamed it, applied it and flamed it again until the coverage was even.

When the stain had dried I sanded it with a medium grit sanding sponge to remove the surface stain while leaving the grain highlighted with the black. I wiped it down repeatedly with isopropyl alcohol on cotton pads to check and see what the grain was looking like after sanding. This process took far longer than the staining and initial preparation. I sanded and washed, sanded and washed the bowl and shank until the grain stood out against the briar.

I sanded the bowl with micromesh sanding pads – wet sanding with 1500-2400 grit to further remove the black stain that was stubbornly sticking in the angles of the bowl and shank. I then gave the bowl a top coat of oxblood stain. My thinking was that the contrast between the black in the grain and the red in the other portions of the briar would make the grain stand out.

When the oxblood stain dried I dry sanded the bowl with micromesh sanding pads to remove some more of the dark stain and make the grain stand out even more. I rubbed the bowl down with olive oil and used it as a medium for the sanding. It worked well to remove the darker areas of the bowl near the shank and along the top edge and rim.

After sanding I took the pipe to the buffer and buffed the bowl and stem with White Diamond to polish the briar and the Lucite stem. I had previously sanded the stem repairs with the sanding sponges to remove the bump of the glue and blend it into the surface. I followed that with sanding the stem with all grits of micromesh from 1500-12000. I wiped the stem down with Obsidian Oil and then gave the bowl and stem multiple coats of carnauba wax to protect and polish it. I finished by buffing the pipe with a clean soft flannel buffing pad. The finished pipe is shown in the photos below. It is cleaned, stained and ready to smoke. I am really pleased with the finished look of the pipe. The yellow mother of pearl looking stem works well with the contrast stain on the bowl.