Well I am known as the visual artist, the mad man, the cowboy with a drill bit! This story is about my custom pipes offering you some history and the reasons why I do what I do.

I enjoy pushing boundaries at times and do so due to my training in the arts up to masters’ level. I do pipe repair and still hold firm that pipes need to brought back to life as close to their original state as possible. I would never dream of doing a custom job on a Dunnie shell for instance, or a pipe that remains in a repairable state.

My “Hot Rods” are custom renditions which I keep in my own collection. These are pipes lying in ICU close to flat line. They are in a poor state, often with busted shanks or missing or broken stems. You name it, these pipes have a terminal diagnosis. From here on I have fun. I tend to push myself a little further each time with the challenge being to save the pipe at all costs. Some I have won and others lost but no matter how bad they are, I give them my best shot.

Now a bit of Pipe lore history from the dark continent, South Africa. Smokers here are few and far between. As RSA is no bigger than the state of Texas our smokers per capita will never service the demand for good pipes and tobacco. We have but a few collectors. The majority are smokers who pride themselves in workhorses such as the famous Keyser pipe smoking OTC heavily doused aro’s in them. Now, we were a British colony until the mid-1960’s so it is not uncommon to find older GBD’s, Pete’s and even antique Dunnies floating around here. As a matter of fact most British pipe makes are here in their dozens with the American and European pipe manufacturers taking a back seat.

During the apartheid years most countries in the world imposed sanction on South Africa reducing the inflow of pipes to a trickle. Being a commonwealth country we were still able to obtain Brit pipes. America and the most of Europe would have nothing to do with us. Most imported tobacco ground to a halt with South African tobacco farmers inventing the most hideous blends the world has ever seen. During the late 80’s and 90’s the South African rand lost plenty of value and after the new ANC Government took charge in 1994 we have been experiencing a slippery slope with the current exchange rate. An example of this is the pound stirling sitting at 12 to 1 and the US dollar close to 9 to 1.

The abolishment of Apartheid and the emergence of the New Democratic South Africa meant that the world re opened trade relations with South Africa. This meant that the tobacco shops locally were now again stocking Italians, Danish and American pipes. Great you may say. Think again! With the current exchange rate, expect to pay an average of $250-00 for a mid-range Savinelli which has established itself well here during the post-apartheid years. So what do we do? The solution is simple. Hunt ebay, import good tobacco and say your prayers that your orders and purchases arrive in one piece and that Mr Import Duty Officer does not sniff you out.

My journey into pipe restoration was born from a need to survive. I needed to learn the trade with speed if I was going to dabble in this pass time. It took years of experimentation and thank the Pope for the internet indeed. I found pipes in barns, begged friends and ex pipe smokers and family members for their boxed pipes to experiment on. I made headway and met some great people along the way. Mike Mitchely “Muddler”, David Peterson from the Virtual Smoking Lounge, Steve Laug, Jan Pietenpauw, Alan Philips from Sturks tobacconist in Cape town, Charl Goussard, Dean Swanepoel and the list goes on. I made friends not only locally but worldwide. We traded, gifted and swopped pipes and tobacco. My friends sent me pipes as gifts with the result being that I have to date Lee von Erck, Rad Davis, Mark Tinsky, Chris Askwith pipes in my collection to name just a few. For this I am eternally grateful.

As soon as my skills were honed I put up a website (www.binsbergenpipes.co.za) in the hope that I may meet fellow smokers and collectors around the world. I was surprised! I met people who wanted pipes cleaned, repaired, restored etc. My client base now reaches the far corner of the globe. What seems to be happening is that most of my friends locally and abroad, shop on ebay and send the pips to me for restoration. The result is that I am paid for my services with pipes, tobacco, etc. as I simply cannot accept money from friends. The regular Jo Soap down the road however, is billed for my services which to date keeps this pass time self-sufficient. I am not making any profit and I am happy with this arrangement as this life style now pays for itself.

A big pipe enthusiasm injection for South Africa came with the inception of the Brotherhood of International Pipe Smokers forum in December 2010. In conversation with a fellow pipe smoker from Cape Town, Dean Swanepoel who is a web designer, we bounced around the idea of the first South African based Pipe Forum. The first question was who would join this forum? After all we are up against the big guns, Pipe Chat, Tamp and Puff, Brothers of Briar, Smokers Forum and many more. We took the leap of faith and soon friends made on other forums came to the BIPS campfire. It was decided to keep BIPS a closed forum holding membership low in order to keep a sound brotherhood medium. Members are recruited on an “invite in” basis only, not that we are snobs but in order to keep a tight nit community of brothers who care for one another. It has become a cyber-home for all the members, a place to kick up feet and enjoy the pleasures of wood and leaf.

In returning to my “hot Rod” pipes, it was important to offer the background history in order for the reader to understand the viewpoint of a South African repairman. Now, where do I find the pipes? Well, I scout antique markets over weekends and public holidays. South African’s seem to be patriotic buggers at heart and such markets are well attended with buyers seeking out Afrikana memorabilia of years past. This is where I find the gems at give-away prices. Make no mistake, they are near dead and price says it all. I pay on average for the pipes you will see here a mere average of R 30-00 ($ 5.00 to $8.00). It was here I noticed the inflow of many Brit pipes, especially GBD’s. These are entry level pipes from the 50’s and 60’s, nothing special at all. GBD Populars and New Standards seem to be in overflow. Also Sasieni seconds destined for international markets stick their heads out once in a while. I have found some big scores too, a 1959 Dunnie Shell in mint condition in its box with booklet and sock, some Peterson’s, BBB’s and Comoy’s either carrying the original names or their second lines. Either way, this makes little difference as we are after old wood which become reborn.

What you are about to see are the finished pipes. Some have made their way into my smoking rotation; others are yet to get there. Either way, welcome a part of my crazy world. In conclusion, most of the pipes were found at markets, others come from friends as far north as Michigan and down south in Mexico City. Unfortunately I do not have before pictures but you may get the idea.

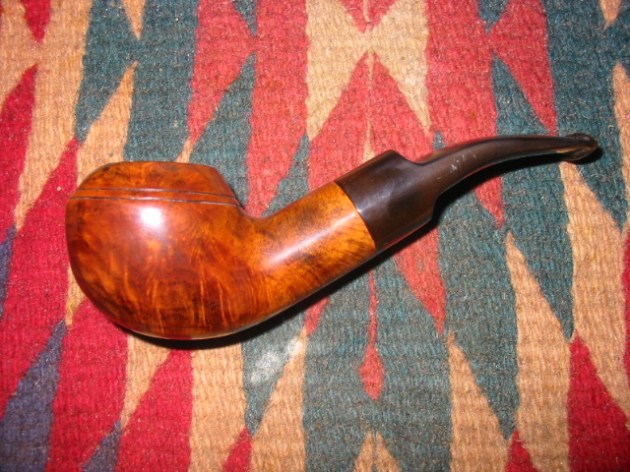

Most of the pipes come to me looking like this, and trust me, this is a good one with a solid heart beat!

The Green Mamba

Pipe: GBD Canadian (Cadogan era, 1980’s) Shape 262

Location: Mexico City

Price: Gift from Eric Hyland (Mr. E)

Diagnosis: Broken Clear Lucite Stem

Sandblasted the stummel. Stained the pipe green. Fabricated a green Lucite stem.

The Fire Starter (Blitzkrieg)

Pipe: GBD Popular, Shape 3781

Location: Cape Town, South Africa

Price: Gift from Alan Philips (Sturks Tobacconist)

Dignosis: Ugly chubby Lovat, a perfect candidate

Sandblasted the stummel as it was full of putty fills. Replaced the stem adding an olive wood shank ring. Sanded the shank and shaded the stem to go from yellow through red to black using leather dye hence the name fire starter. The process is time consuming as the stains go on and sanded with 1200 grit paper, restained and so on in order to obtain the shading in colour.

The Hippo

Pipe: Carey Magic inch Pipe

Location: Michigan, USA

Price: Gift from Chuck Rewalt (Velveteagle)

Diagnosis: Smooth bowl full of fills and dents. Chewed mouth piece. Heavily smoked and caked.

Sandblasted the stummel. Stained it black. As this is a “magic inch” pipe the stem needed to be salvaged. I sanded the teeth marks out and reshaped the bit. This was difficult as the stems are plastic castings. I added a hippo bone shank ring stained green that I got from the pipe maker Jan Pietenpauw.

The Black Beauty

Pipe: GBD Popular, shape unknown

Location: Johannesburg, South Africa (antique market)

Price: R 20-00 (ZAR)

Diagnosis: Snapped stem, heavily smoked, Burn mark on bowl from leaving the pipe in an ashtray next to a burning ember or cigarette. This was a major eyesore.

Replaced the stem. Did not opt for any shank adornments here. Sanded the bowl and stained it black to hide the burn mark in the wood.

The Red Head

Pipe: GBD Popular, shape 3781

Location: Pretoria, South Africa (antique market)

Price: R20-00 (ZAR)

Diagnosis: Broken stem. Heavily smoked, dings on rim from knocking pipe on hard surface.

Under all the dirt, grime and dents the wood on this one was good. I lost 0.5 mm on the rim to remove dents. Sanded the bowl and restained it. Replaced the stem adding an olive wood flush shank ring and contrasting it with a blue raised Lucite ring.

The Reject

Pipe: GBD, Cadogen era Billiard, shape unknown, stamped RJ (I take it that GBD stamped the pipe reject as it carries no marking on the stummel but has GBD printed on the stem)

Location: Pretoria, South Africa (antique market)

Price: R 50.00 (ZAR)

Diagnosis: Cracked shank. Stem was intact but it was a yellow Lucite saddle with restricted draw.

Heavily smoked. Dings on bowl.

A tough call. Repaired cracked shank by spinning brass sleeve to fit flush on the shank. Added olive raised shank ring. Sanded and restained the bowl.

The Half & Half Virgin

Pipe: GBD Virgin, Shape Unknown

Location: Ghana, Africa.

Price: Gift, Duncan Nebbe (Rhodesian). Scored in a lot of GBD pipes on Ebay. Most were cleaned, this one flat lined.

Diagnosis: The lot of pipes were in a barn or some place exposed to the elements for many years (we suspect). Fine cracks appeared on the outside of the bowl. Stem broken. In a shocking state. It lay around the in the trash box for some weeks before it called to me.

We all know GBD Virgin are not blasted pipes due to the quality of the wood. This one needed to be blasted to remove the surface cracks in the wood. I masked the shank in order to retain some faint nomenclature and the word ‘Virgin’. Bowl restained and a new stem fitted. Tambotie shank ring added.

The MOERSE Billiard

Pipe: Byford/Orlik, shape unknown

Location: Pretoria, South Africa (Hospice charity shop)

Price: R15.00 (ZAR)

Diagnosis: Heavily smoked. Dings on rim from knocking pipe on hard surface. Dings and fills on the bowl. Stem clogged and chewed.

The Byford was a system pipe in its heyday. The stem consisted of 3 tubes running back and forth in the stem in order to cool and purify the smoke. If it is not cleaned regularly the system gets clogged and there is nothing one can do to save it. I replaced the stem. The alu butt on the shank comes standard with the pipe. It was cleaned and polished. Buckeye Burl shank ring added. Bowl sanded and stained.

LOJ se Vlieg Masjien (Lord Oom Jan’s Flying Machine)

Pipe: Keyser Hygienic patent, shape Unknown.

Location: Pretoria, South Africa (Antique market)

Price: R10-00 (ZAR)

Diagnosis: Cracked shank. Broken Stem. Heavily smoked.

For those of you who are familiar with the Keyser pipe, this looks nothing like it. I may get shot for tampering with tradition South African pipe lore but this is how it came out. Named after the South African carver Jan Pietenpauw (LOJ) as parts for the pipe were salvaged from his reject box in order to fix the pipe. Brass shank ring added to repair the crack in the shank. Buckeye burl extension added to seat the shank extension. Stem was replaced by spinning down a pre mould to create a military mount fit.