This one is another mystery to me. Because I am always picking up these old timers I have a habit of researching out as much information as I can once they have arrived and I can see the stamping and hallmarks up close. This one bears the hallmarking of the Anchor which tells me it is made or assayed in Birmingham, the Lion which tells me it is Sterling silver and the date letter that though worn looks to be a capital E which would date it as an 1850 pipe. That is as close as I can tell to the date and time frame for this old timer. There is also a Makers Mark in the silver stamped BW and the briar of the pipe is also stamped BW. I cannot find any information on that maker in all of my searching so that is where it stands. If anyone reading this can shed light on the initials and what they may refer to I would deeply appreciate it. Until then I have a nice old bulldog from 1850 that smokes exceptionally well and it is a mystery regarding its maker.

When the pipe arrived it was in rough shape. The silver was very tarnished and dull looking. It was also scratched and much worn in places. The bowl had a very spotty finish with just the remnants of the original stain. The rim was tarred and the bowl heavily tarred and caked. The stem is made of some amberoid substance or may be Bakelite. It seems to be a softer material than the hard Bakelite. It has a bone tenon that was over turned so the stem was off to the side. The button also has an orific hole in the button instead of the newer slotted button.

I reamed the bowl and cleaned it with Isopropyl alcohol and many pipe cleaners and cotton swabs. I sanded the bowl to remove a bit more of the cake and take it back to the wood. I then put the bowl in an alcohol soak to remove the remnants of finish and the grime that was worked into the surface of the pipe. Once I removed it from the alcohol bath I re-stained it with Cherry stain. The stem was crackled a bit – lots of tiny spidering all over the surface so I did not want to chance using alcohol on it as it can cause more spidering and cracking. So I cleaned it with Gojo an all purpose hand cleaner with grit suspended in liquid soap. I ran it through the stem repeatedly to remove the tars and grime inside the airway. When it was clean I rinsed it with warm water to remove any residual soap. I sanded the tooth chatter and used my needle files to recut the button as it was pretty worn. I sanded and polished the stem with micromesh pads 1500-6000 grit as is my usual practice. I also heated the bone tenon with hot water and readjusted the fit to the shank. Upon completion of the refurbishing above the pipe and stem were given a final buff with carnauba wax. I also gave the black leather pipe case a cleaning with leather renewer and a coat of wax as well.

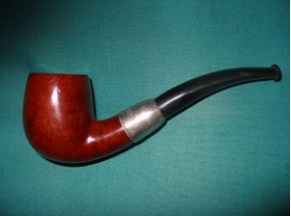

Here is what it looked like when I got it from EBay

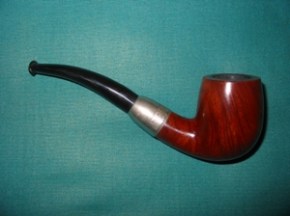

Here is what the pipe looks like today