Blog post by Fiona Adler, translation Steve Laug

I have been doing some research into BBB pipes for sometime now because of my own interest in the brand and I found an online article in French. (The original article was produced with the assistance of Fiona Adler. I want to thank Guillaume Laffly for giving me this new information on the origin of the material in French.) I have adapted the article below from a google translation that I did of the article on http://www.fumeursdepipe.net/artbbb.htm (I alone am responsible for the English translation and any errors probably are the result of my poor translation!)

Origin and history of Adolph Frankau and Co. Ltd.

Adolph Frankau arrived in London in 1847 and quickly grasped the opportunities which the enlarging tobacco market introduced. He started “Adolph Frankau and Co.” and began importing meerschaum pipes and tobacco supplies. The Company took a young 14 year-old boy, Louis Blumfeld under its wing. The Company quickly thrived and did so until the untimely death of Adolph Frankau in 1856. His widow decided to sell the company.

Thomas Carlyle (1795-1881), author of “Hero and worship of the heroes” came on the scene at this point. He recommended that the widow Frankau not sell, but rather that she should entrust the future of the company into the hands of young Louis Blumfeld, then 18 years old. Carlyle had to have had a very high opinion of the young Louis to make this recommendation, and his trust proved to be justified as Blumfield took care of the company with enthusiasm and bottomless energy. Louis quickly realized, as others had before him, the potential of the newly acknowledged pipes made of briar.

Louis Blumfeld developed important international trade relations from the beginning, and had particular success in Canada, Australia, New Zealand, India, Europe, as well as Switzerland and Denmark. The USA had never been an extraordinary market for the company, but nonetheless a subsidiary was opened in New York. His commercial strategy focused on the countries of British Empire. Just prior to 1914, Frankau & Co. was the sole agent for Ropp Cherry Wood pipes in the United Kingdom and its colonies.

While BBB is the most widely known of Frankau & Co. pipes the company also produced several other brands of pipes: Capt. Kidd, Fairway (” F ” in white; FAIRWAY / LONDON MADE / ENGLAND), Frankau’ s (London Made in England), Glokar, Major Daff, and Snap-Fit. It also seems that Ultonia and Nec Plus Ultra must be considered to be brands in full measure, in spite of the fact that they were introduced as being product lines under the label BBB. It would explain their absence in many of the BBB catalogues.

The necessity of making briar pipes in London became more urgent, that’s why, at the turn of the century, Frankau & Co. opened a warehouse and offices at 121 Queen Victoria Street, an export service at Upper Thames Street and a plant in 1898 at Homerton, High Street 112 (then 154). The Homerton plant lasted into nineteen-eighties when Cadogan regrouped its manufacturing activities to Southend-on Sea.

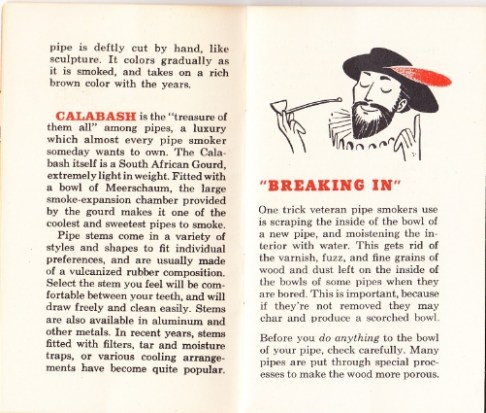

In those days, Frankau & Co. also produced calabash pipes. They used calabashes that came originally from Southern Africa. Supply of the calabashes became more difficult to maintain due to the growing demand for them. BBB set up a special department to make calabash pipes. They used meerschaum to make the bowl while some of their rivals used asbestos or plaster of Paris. The manufacture of calabash pipes survived until the war in1914/1918. The war destroyed the supply of calabashes from South Africa.

The 1920s were not an easy decade for pipe producers. Frankau & Co was purchased by “Oppenheimer and Co. Ltd1”. Also during this decade Comoy’ s of London, Dr. Plumb and Loewe & Co. came under the control of Oppenheimer. The purchase of all of these various brands pushed the company to create “Cadogan Investments Ltd.2” at Cadogan Square, London, in the 1930s, to manufacture and sell its pipes. The plant at Homerton passed under the control of “Marechal Ruchon & Co.” (In 1970s, the plant took the name of “Fairfax Traders”), and continued producing BBB pipes in a traditional way. They finished pipes with a silver ring and stampings. However, BBB continued, as an independent company within the Cadogan Group. BBB concentrated on making a certain number of system pipes and on new finishing processes.

Richard Esserman thinks that Dunhill subcontracted the manufacture of stummels to BBB for the Bent Magnums until 1923. In fact, when the companies within the Cadogan group argued with one another, a new plant was established in Stratford, Carpenters Road. They also bought machines from Zuckerman as they were more efficient. The finishing workshops were closed, and pipes were finished in Aldershot and sometimes also in Shoeburyness.

In this era, it was a current practice in trade to give surplus stummels to other companies at agreed upon prices. Cadogan sold Rank I stummels to Dunhill, and bought Rank II, III and IV stummels from Dunhill. But they did not finish pipes for other companies: to sell Rank I stummels to Dunhill was more beneficial than making them into pipes!

The BBB Logo

The initials BBB in a rhombus were quickly used as a symbol for the company, and that trademark was the first to be recorded when “Trade and Marks Act” took effect in 1876. Rather strangely, BBB registered under two numbers, numbers 39 and 40. In number 39, the acronym BBB in the rhombus (dates from deposit: January 1st, 1876; published on May 3rd, 1876 in page 21 of the Trade Mark Journal) for the class 341 (Tobacco, raw or fabricated and cigarettes), in number 40, a simple B for which no picture is available (the same references of store and publication) for the class 50 (fabricated Property from ivory, in bone, wooden, substantially plant or animal, pipes with tobacco, cigars and cigarettes (cigar and cigarette tubes). Note that Oppenheimer registered BBB again (number 39) for a new logo under the number 2288663 (December 20th, 2001; published on February 13th, 2002 in page 2634 of the Trade Mark Journal) for classes 14 (cases with cigar and cigarettes, soft packages of cigars and cigarettes, doors-cigars and cigarettes, all in precious metals) and 34 (Tobacco and products of tobacco, articles for smokers, pipes, tobacco pouches, door – pipes, lighters, equipment of cleaning for pipes, doors-cigars and cigarettes, cases with cigars and cigarettes, humidors). At the European level, Oppenheimer registered BBB under the number 002100907 (February 22nd, 2001, date of recording: October 7th, 2002), for classes 14 and 34 and under the number 0863111 for the class 34 (October 20th, 2005).

BBB Production

Some think that the first BBB pipes were imported, and that initials were intended to stand for Blumfeld’s Best Briars. Later these initials came to be understood as standing for Britain’s Best Briars.

At first, BBB produced two qualities of pipes. The one, BBB Own Make, became BBB Best Make, other pipes simply being stamped BBB. There are reasons to think that the Own Make was produced in fact in London (Reject pipes were stamped R). While simple BBBs were imported until the beginning of the 20th century. It is probable that the regular line of BBB pipes were imported from Saint-Claude, France.

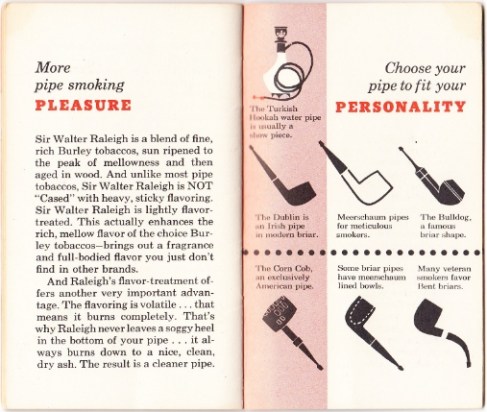

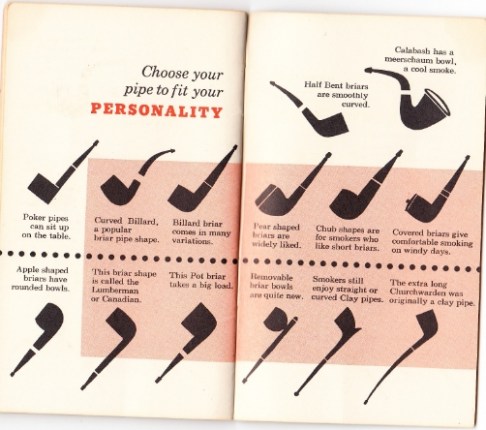

The BBB collection followed along similar lines as other pipe producing companies during the second half of the 19th century. Shapes were similar to the popular models in vogue during that time with a predominance of bent pipes. Some of them had a silver ring. At the same time, BBB continued to deliver meerschaum pipes.

BBB was probably the first to offer pipes made to accommodate a paper filter. The Mackenzie, which was available in two qualities (Mackenzie, second brand of BBB, could have been produced in Republic of Ireland. Pipe stems were made of vulcanite). This technique dates from around 1900 as is stated in a letter dated from August 27th, 1891 from Mr. Morrel Mackenzie (1837-1892) in which he suggest that they make models with a longer stem. The Mackenzie brand survived into the 1960s.

It is thought that BBB was one of the first to call the pipes they had conceived with a long shank for a cooler smoke a “Lovat”. However, “Friedlands” could have adopted this name at the same time. Lovats appeared long before 1914 and were offered for sale by BBB in four different sizes, of which a series were stamped Highland. Colonel Henry Francis Fraser (1872-1949), Lord of Lovat, must have enjoyed the advertising of this shape made in his honour. It is still a popular shape at present. While BBB briar pipe shapes were similar to those of other brands, their models developed a very sought-after distinct character by the collectors. BBB earned the gold medal at the French-British Exposition in London in 1908 (Frank Bowcher, on 1864-1938) and at the World Fair and International in Brussels in 1910, the Medal of Godefroid Devreese (1861-1941). You can find pictures of these medals, notably on the advertising brochures of the 1950s and 1960s.

In this era the common practice was to set a pipe’s value by the material the stem was made of: ebonite, horn, amber, ambrolith etc. Also, price varied according to the size of the pipe. For instance, in 1914, the wholesale price of a simple billiard varied between 15 shillings and 22 shillings and 6 pence because of the size of the pipe and flock (no screw or tenon). Though this generally was true it seems that there were exceptions; for instance a Liverpool of five inches long with a stem in genuine amber had a wholesale cost of 12 shillings in larger quantities; the same pipe with a stem of ambrolith cost 19 shillings. BBB made different special series of pipes such as Chubby, Golfer, Dreadnought (probably named after different warships), Bellerophon (sic) and Cutty (small models). BBB offered some 20 lines of pipes that had different clever combinations of stems, finishing and decoration. Some of them had a silver ring. Around 1910, BBB Own Make pipes sold for 2£ 10 shillings while pipes only stamped BBB were sold for 5-6 shillings.

In the 1930s, the top pipe of the line was “BBB Best Make” with variants such as “Great Dam” and “Ultonia Thule”. The BBB Carlton, sold retail in 1938, was endowed with a complicated stinger system; the same system was also used on the BBB London Dry. The Blue Peter was not stamped BBB but BBB Ultonia, and BBB Two Star (**) was the stamping on lesser quality pipes. The calabash pipe was removed from the catalogues at this time, but some pipes with cases and some meerschaum pipes were still produced. Shapes of BBB pipe were typical of other companies pipes made in this era: half were billiards, some princes and bullcaps, bulldogs and some bents. It is also in this period that the inlaid metal BBB was put on more upscale pipes, while series of lesser quality had only the stamped BBB on the stem.

During the middle of 1950s and 1960s, BBB lines were comparatively stable. The top pipes of the line were stamped Own Make “Rare Grain”, followed by Own Make “Virgin”, Own Make “Walnut” and finally Own Make “Thorneycroft”.

Today, Cadogan uses Spanish briar for most of its pipes, and reserves the Moroccan briar for the production of high quality pipes. Before being sent to them for manufacture into pipes, the briar has been dried and cured for a time period of between 6 and 12 months.

To avoid any confusion about the ranking systems of their pipes in the Cadogan Group brands the company adopted a system of eight common ranks for all of its brands. Rank A is briar with nice grain, without any visible imperfections. Rank B has nice grain, but with some small black points and maximum of three sand pits which will be filled. Rank “Best Make” also has nice grain, with maximum of five small sand pits. The stummels with grain of variable quality and maximum six sand pits are ranked MB. The second rank pipes are of briar of mediocre grain but without defects or of nice grain but with up to eight fills or two big sand pits. The third, fourth and fifth ranks are given to pipes whose quality decreases proportionately.

1Adolph Oppenheimer started an import/export company in 1860, and his brother, Charles, joined the company later that year. Adolph retired in 1870 and moved to Germany, where he became British Consul then Consul general, letting Charles take the control of business. Louis Adler, who was the brother-in-law of Oppenheimer, became a colleague when Adolph left the company. Both brothers did not have heirs, so the ownership of the company passed to the family Adler. By 1870, the company imported GBD pipes into Great Britain from Paris. The association of Oppenheimer with GBD was such a success that in 1897, Oppenheimer became the sole agent of the French company. Five years later, the French owners of GBD, Marechal Ruchon and Co., merged with A. Oppenheimer.

2Cadogan’s slogan, “Pipemakers Since 1825” refers back to the first clay pipe which Francois Comoy fabricated in 1825. Cadogan’s pipes were fabricated in numerous places disseminated around London and to Saint-Claude, but with the purchase of Orlik Pipe Co. In 1980, Cadogan regrouped the entirety of its manufacture in the new plant of Southend-on-Sea, plant especially constructed for pipe making industry. Cadogan continues to fabricate GBD, Comoy’s of London, BBB, Dr. Plumb, Loewe and Orlik pipes (since 1980). They also make Kaywoodie pipes for the British market and have recently agreed to make Sasieni pipes for James B. Russell.

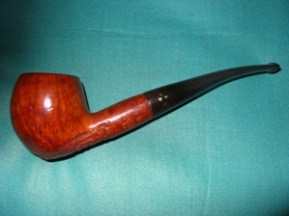

I have attached a few pictures of some of my BBB’s. I love these old pipes and have quite a few.