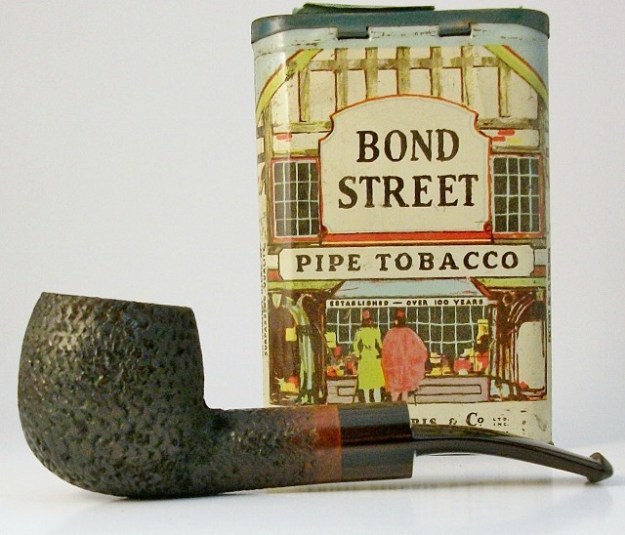

I received my third Bill Boyle Pipe in the post from Bill several weeks ago. I have two other pipes that he made for me during the past several years and I have watched the progress in Bill’s craftsmanship and work in these pipes and through watching the variety of pipes that appear on his website and through the reviews others have made. Bill and I have talked about pipes since the days that he started making modified cob pipes. He has come a long way through the years and this new pipe reflects a huge step up in his work in my opinion. The previous two pipes are amazing smoking machines but his stem work was not perfected and was a bit too thick to my liking (See the comparative pictures below). The taper of the stems on the early ones was more abrupt while this one is very smooth and flowing. His internal mechanics have always been spot on but it was the finish work on the stem that needed to be refined. This new pipe is a step up in every way. It is a beauty to be sure. The length of the pipe is 5 inches and the bowl height is 1 5/8 inches. The chamber diameter is 3/4 inches and depth is 1 3/8 inches. It weighs 40 grams or 1.4 ounces. It is carved from Italian block according to Bill’s website and sports a hand cut Cumberland stem. The pipe is a small apple shape with a ¼ bent stem that fits well in the hand.The stamping reversed B and B and is one of the last of this stamping that will be used as Bill has stepped up his production and has a new stamp for Bill Boyle Pipes.

The finish on the outside of the pipe is rusticated in a finish that is quite different from the other two rusticated pipes I have purchased from Bill. It is not a heavy deep rustication on this pipe but more of a rustication pattern that has the appearance of strands of a rope. There is a still a very tactile feel to the rustication on the bowl and shank but it does not really have the look of randomness that was in his more heavy rustication. It is a nice variation and I think that it adds to the overall appearance.

On the rim of the pipe Bill rusticated it over the curve and then almost countersunk the bowl. The rim thus forms two levels and a bit of step down from the rusticated edge to the smooth edge that is below and then drops into the bowl. The rustication where the shank and bowl meet is a bit heavier than what is on the rest of the bowl and a bit rougher but does not detract from the other rustication. It is merely a variation that makes me wonder if there is not a flaw or sandpit in this area of the pipe (indeed Bill confirmed this is so in a later email). The staining on the briar appears to be a blend of darker/medium brown/black with an oxblood over stain that is a nice contrast. In the light it appears to have a dark oxblood tinge that comes out well in contrast to the browns in the under stain. It really goes well with the Cumberland stem. Bill has matched the colour of the Cumberland stem with his choice and combination of stains. Great work on the finish Bill.

On the rim of the pipe Bill rusticated it over the curve and then almost countersunk the bowl. The rim thus forms two levels and a bit of step down from the rusticated edge to the smooth edge that is below and then drops into the bowl. The rustication where the shank and bowl meet is a bit heavier than what is on the rest of the bowl and a bit rougher but does not detract from the other rustication. It is merely a variation that makes me wonder if there is not a flaw or sandpit in this area of the pipe (indeed Bill confirmed this is so in a later email). The staining on the briar appears to be a blend of darker/medium brown/black with an oxblood over stain that is a nice contrast. In the light it appears to have a dark oxblood tinge that comes out well in contrast to the browns in the under stain. It really goes well with the Cumberland stem. Bill has matched the colour of the Cumberland stem with his choice and combination of stains. Great work on the finish Bill.

The stem itself is the best of the three stems my BB pipes. His stem work has really developed and this is by far the most well executed of the three. It is a nicely cut saddle stem. The saddle is well cut and the finish on the 90 degree angles of the saddle is smooth and polished. There are no machine or file marks. He has done a great job shaping this part of the stem. The blade of the stem is thin and has a good even tapered flow from the saddle to the button. It is matched in terms of angles on the top and the bottom and on the left and right side of the stem. The design along with the slight bend makes it fit very comfortably in the mouth. It also rests well enough that it can be clenched quite easily. The tenon is cut from the stem material and is funneled at the end for good mechanics. The button is exactly the way I like them – thinner on the edges with a gentle rise at the centre top and bottom. The edge of the button is a good sharp angle to the stem and looks sharp. It fits well behind the teeth for a comfortable feel. The draught hole/slot in the end of the button is also funneled to deliver a mouthpiece that has the same diameter from start to finish. Comfortable and well executed. A pipe cleaner passes easily through the pipe with no obstruction. I have posted photos below of my other two of Bill’s pipes so that you can see the progress and development in his stem work.

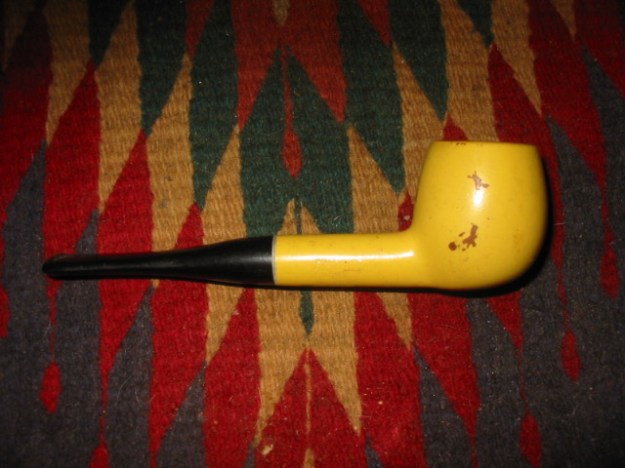

My first one is the Christmas pipe I had him make for me. The rustication is great and the shape is well done. Note the thickness of the stem from the saddle to the button and also the thick button on the end of the stem. I reworked this stem when I received it. I thinned it down, flattened it out and thinned the button as well. I worked it until it was comfortable for me.

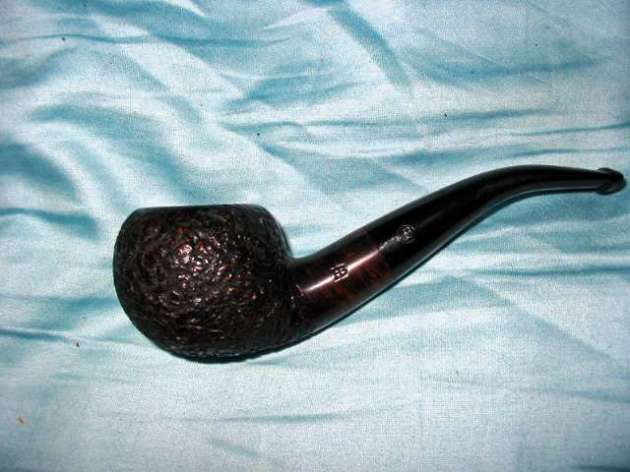

The second is an apple that caught my eye on one of his email updates. It was made later than the first one. The stem work is definitely improved. Note that the stem is thinner than the one above but there is a definite crown on the stem. It is almost oval in shape from an end view with thin edges and a rise/crown toward the middle of the stem. There is also an abrupt drop from the stem to the button area. The angle is quite sharp. He has also thinned down the button and made it more comfortable. The stem work is getting better and the feel in the mouth is better but it is still not quite there.

The next photo shows the same view of the newest (the third) Boyle pipe that is in my rack. Here the improvement on the stem is marked. Note the thinness of the stem from the saddle back to the button, the flatness of the stem from side to side and the improved shape of the button. To me the development and improvement can be traced in these three photos. All three pipes smoke exceptionally well. Each one is well made. But each one represents a step in Bill’s development as a pipemaker and particular in the way he fashions his stems.

The mechanics of this new pipe are well done. The bowl chamber came without a bowl coating and the wood was sanded very smooth. There were no pits or checking in the bowl. The countersunk inner edge of the rim gave a distinctive look to the pipe that I was not sure about at first. Since I have been smoking it the briar is darkening (not char or tar) just the natural darkening of heat and oils and it looks great.The draught hole is centered at the bottom of the bowl and seems to have a slight slope from the bottom to the top of the airhole. There is a very easy and open draw to the pipe. The fit of the stem to the shank is very good. Smooth and tight. The tenon sits deep in the mortise – if not exactly the same length then impressively close! The fit of the tenon is also smooth. The drilling of the draught in the shank is slightly high in the end of the mortise. It is not in the middle of the mortise. The tenon on the stem is drilled to match it and there is no misalignment to the two. The air pulls clearly through the pipe with no whistling at all. Using a light to shine through the various airways reveals smoothly executed airways on the inside. Very nice work on the drilling Bill. Your matching the airway in the mortise to the tenon end was well executed.

I have been smoking it since I received it and am very happy with it. I have smoked Virginia flake and broken flake tobaccos in it and it packs easily and stays lit. And I have to say that like all three of Bill’s pipes that I have the draught on the pipe is superb. Smoking it is a pleasure and is uncomplicated and effortless. I found that without exception Bill’s pipes smoke smooth from the get go with none of the new pipe break in woes. Thanks Bill for a well-made pipe that smokes as good as it looks! If you are interested in Bill’s work check out his website and look at the gallery – he does commissioned pipes as well. Here is the link: http://www.billboylepipes.com/