by Steve Laug

The next pipe on the table is one that we picked up in the lot from a good friend in Barrington, Rhode Island, USA on 08/22/2024. The smooth finish on this Italian made pipe and the Radice stamping are what caught our eye. It is stamped on the left side of the shank and reads Radice. On the right side it is stamped Hand Made [over] In Italy with the shape number 31 next to it. It has a classic Walnut Brown stain on the smooth finish that is a stark contrast to the short, stubby acrylic stem. It combines a tall stack shape bowl with a long, round Liverpool style shank and a taper stem. The bowl was clean and appears to have been recently reamed. It was a lightly smoked and well cared for pipe. The inner edge and the top look good though there is some darkening and some light lava on the top. The stem looks very good and has two small tooth marks and light chatter on the top and underside ahead of the button. The Radice inset Briar two spot logo is on the topside of the stem and looks to be in good condition. Jeff took some photos of the pipe to show the general condition of the pipe before he started his clean up.

He took some photos of the rim top and bowl from various angles to give me a clear picture of the condition of the rim top and bowl. It is quite clean and the inside of the bowl is very clean and shows that the pipe has been lightly smoked. He included photos that show the top and underside of the stem. It is as described above.

He took some photos of the rim top and bowl from various angles to give me a clear picture of the condition of the rim top and bowl. It is quite clean and the inside of the bowl is very clean and shows that the pipe has been lightly smoked. He included photos that show the top and underside of the stem. It is as described above.

Jeff took some photos of the sides and heel of the bowl to show the condition of the finish on the pipe. The photos showed some great grain around the bowl and shank even with the grime in the finish. It is a great looking piece of briar.

Jeff took some photos of the sides and heel of the bowl to show the condition of the finish on the pipe. The photos showed some great grain around the bowl and shank even with the grime in the finish. It is a great looking piece of briar.

He took photos of the stamping on the sides of the shank. It was clear and readable as noted above.

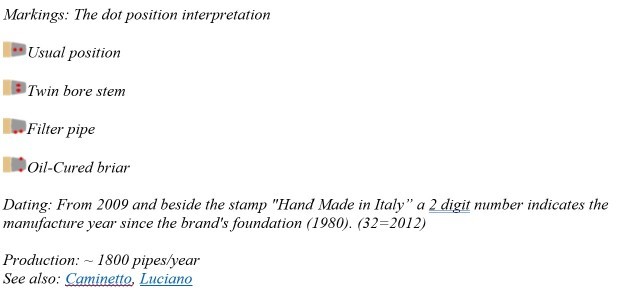

He took photos of the stamping on the sides of the shank. It was clear and readable as noted above. I started my search on the brand by looking on Pipephil’s site to see if there was any information on the Radice Handmade brand (http://www.pipephil.eu/logos/en/logo-r1.html). The line was not included there but there was some information in the side bar on the dot position on the stem and how to interpret them. It also gives some helpful information on the number stamp on the right side of the shank. I have included that portion below.

I started my search on the brand by looking on Pipephil’s site to see if there was any information on the Radice Handmade brand (http://www.pipephil.eu/logos/en/logo-r1.html). The line was not included there but there was some information in the side bar on the dot position on the stem and how to interpret them. It also gives some helpful information on the number stamp on the right side of the shank. I have included that portion below. From the information above I learned that the dot position is the usual position for the brand. That matched the stem well. The number on the shank side – 31 – actually turns out to not be a shape number at all. Rather it is a date number. Using the formula above – 1980+31 = 2011. The pipe in hand was made in 2011.

From the information above I learned that the dot position is the usual position for the brand. That matched the stem well. The number on the shank side – 31 – actually turns out to not be a shape number at all. Rather it is a date number. Using the formula above – 1980+31 = 2011. The pipe in hand was made in 2011.

I turned to Pipedia to the article on Radice pipes and the birth and development of the brand (https://pipedia.org/wiki/Radice). I have included the information that I found there below.

Luigi Radice, born 1939, took a piece of briar in his hands for the first time in 1961, when he was employed at Carlo Scotti’s Castello in nearby Cantu.

After lengthy experience, he founded, together with Peppino Ascorti, the famous “Pipa del Baffo”, the “Caminetto” which through 1974 and 1975 made wealth with the precious cooperation of Gianni Davoli, Milanese distributor.

In 1980 Luigi undertook a new adventure, founding his own brand: the Pipa Radice. From the beginning his son, Gianluca, joined the workshop, together with Luigi’s father, Paolo Radice, who helped in some basic steps of production.

Only later my brother and I started working together with our father, trying to learn the secrets and the mastery to be able to create a pipe which could join artisanal estrus(?) to functionality.

We have always trusted the professionalism of Italian briar cutters to obtain the raw material. We season the briar in our workshop for at least three years. We believe that it is enough to produce a perfect pipe.

Our shaping is pretty diversified. A distinguishing feature is the use of various options, like the faux-bamboo shank or silver band or save-rim, hand engraved by Luigi.

About pipes for completely dedicated collectors, we would like to mention the several variations of pieces made using buffalo, moufflon, deer or roe horn.

The creative idea and the study of the technical side, lead us to invent pipes with a twin bore mouthpiece, coupled with a special production of oil cured pipes, taking inspiration from old English skills.

We have recently introduced the use of ebonite(vulcanite) mouthpieces, to satisfy the requests of our fellow pipesmokers.

Radice is a pipe which is continually evolving, keeping alive the treasured experience of 50 years of pipemaking of our father Luigi.

Now it was time to work on the pipe.

Armed with that information I turned to work on the pipe itself. Jeff had done a great job cleaning up the pipe as usual. He cleaned up the inside of the bowl with a Savinelli Fitsall Pipe Knife. The rim top and the inner edge of the bowl are in excellent condition. The bowl walls looked very good. He scrubbed the interior of the bowl and shank with shank brushes, pipe cleaners, cotton swabs and alcohol to remove the tars and oils. He scrubbed the exterior of the pipe with Murphy’s Oil Soap and a tooth brush to remove the grime from the finish. He scrubbed the inside of the stem with alcohol and pipe cleaners. He scrubbed the exterior with Soft Scrub and then soaked it in Briarville’s Pipe Stem Deoxidizer. He washed it off with warm water to remove the deoxidizer. The stem looked very good. I took photos of the pipe before I started working on it.

I took close up photos of the bowl, rim top and stem to show how clean the pipe was. The bowl was clean and the rim top and the inner edge look beautiful. The stem was clean and the tooth marks on the topside are visible. The chatter is light and hardly visible.

I took close up photos of the bowl, rim top and stem to show how clean the pipe was. The bowl was clean and the rim top and the inner edge look beautiful. The stem was clean and the tooth marks on the topside are visible. The chatter is light and hardly visible. I took photos of the stamping on the sides of the shank. It is very clear and readable and read as noted above. I also removed the stem from the shank and took photos of the pipe to show the look of the parts.

I took photos of the stamping on the sides of the shank. It is very clear and readable and read as noted above. I also removed the stem from the shank and took photos of the pipe to show the look of the parts.

I polished the bowl and shank with 1500-12000 grit micromesh sanding pad – dry sanding it with the pads. I wiped the bowl down with a damp cloth after each pad. It began to take on a deep shine.

I polished the bowl and shank with 1500-12000 grit micromesh sanding pad – dry sanding it with the pads. I wiped the bowl down with a damp cloth after each pad. It began to take on a deep shine.

The exterior of the bowl look better after sanding. I worked some Before & After Restoration Balm into the briar with my finger tips. I let it sit on the bowl for 10 minutes and then buffed it off with a paper towel and soft cloth. The product is a great addition to the restoration work. It enlivens, enriches and protects the briar while giving it a deep glow. It is a product I use on every pipe I restore.

The exterior of the bowl look better after sanding. I worked some Before & After Restoration Balm into the briar with my finger tips. I let it sit on the bowl for 10 minutes and then buffed it off with a paper towel and soft cloth. The product is a great addition to the restoration work. It enlivens, enriches and protects the briar while giving it a deep glow. It is a product I use on every pipe I restore.

It was ready for the next step. I used a folded piece of 220 grit sandpaper to sand out the tooth marks and chatter on both sides of the stem. It did not take too much sanding and they were gone.

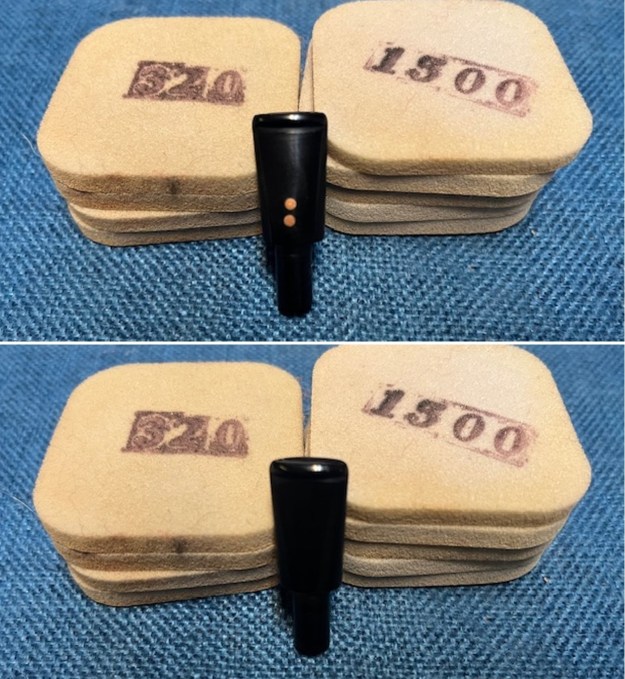

It was ready for the next step. I used a folded piece of 220 grit sandpaper to sand out the tooth marks and chatter on both sides of the stem. It did not take too much sanding and they were gone. I sanded the stem further with 320-3500 grit sanding pads and wiped the stem down after each pad with some Obsidian Oil on a cloth. The shine is coming back beautifully.

I sanded the stem further with 320-3500 grit sanding pads and wiped the stem down after each pad with some Obsidian Oil on a cloth. The shine is coming back beautifully. I polished it with micromesh sanding pads – dry sanding with 1500-12000 grit pads and wiping the surface down with Obsidian Oil after each sanding pad. It is really shining. I polished it further with Before & After Stem Polish – both Fine and Extra Fine. I gave it another coat of Obsidian Oil to finish this step.

I polished it with micromesh sanding pads – dry sanding with 1500-12000 grit pads and wiping the surface down with Obsidian Oil after each sanding pad. It is really shining. I polished it further with Before & After Stem Polish – both Fine and Extra Fine. I gave it another coat of Obsidian Oil to finish this step.

This Radice Hand Made in Italy Stack/Liverpool with an acrylic taper stem is a great looking pipe now that it has been restored. The beautifully grained finish really works well with the shape and the polished finish is stunning. I put the stem back on the bowl and carefully buffed the bowl and the stem with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished 2011 Radice Stack/Liverpool fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 2 inches, Outside diameter of the bowl: 1 3/8 inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 41 grams /1.45 ounces. I will be putting it on the rebornpipes store in the Italian Pipe Makers Section shortly. Let me know via email or a message if you are interested in adding this pipe to your collection.

This Radice Hand Made in Italy Stack/Liverpool with an acrylic taper stem is a great looking pipe now that it has been restored. The beautifully grained finish really works well with the shape and the polished finish is stunning. I put the stem back on the bowl and carefully buffed the bowl and the stem with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished 2011 Radice Stack/Liverpool fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 2 inches, Outside diameter of the bowl: 1 3/8 inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 41 grams /1.45 ounces. I will be putting it on the rebornpipes store in the Italian Pipe Makers Section shortly. Let me know via email or a message if you are interested in adding this pipe to your collection.

As always, I encourage your questions and comments as you read the blog. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipe men and women who hold our pipes in trust until they pass on into the trust of those who follow us.