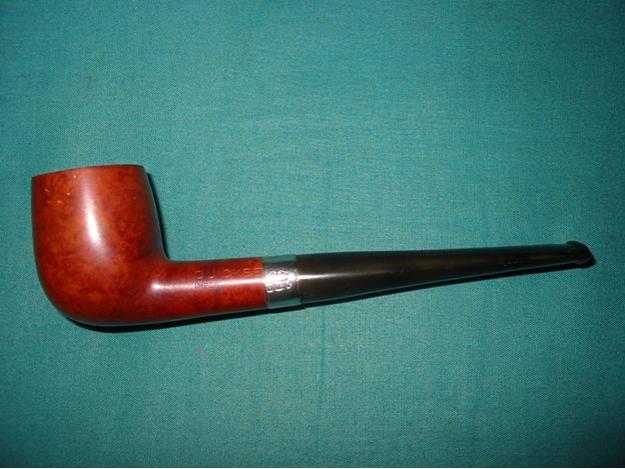

In an earlier post on Malaga pipes and their maker George Khoubesser, https://rebornpipes.wordpress.com/2013/02/09/george-khoubesser-and-malaga-pipes/, I mentioned that I wanted to hunt down a pipe. Not long after that post I was able to pick up this bulldog. It is a rusticated pipe with some smooth patches like those done by GBD on some of their pipes. This one is stamped Malaga in quote on the upper left side of the shank and Custom Carved on the lower left side of the shank. The pipe was in fair shape. The bowl needed to be reamed as the little cake that was present was in the top half of the bowl. The bottom of the bowl had cobwebs in it. The shank inside was very clean. The stem had some oxidation and a small amount of tooth chatter but was in good shape. The rim had a burned area on the front right and it had created a small dip in the rim. The shank was cracked in multiple places near the stem. It looked like it had been repaired and there was some darkening around the place where the shank met the stem that seemed to indicate that a band that no longer was present had once been in place. The first series of eight photos show the items that I mention above. Looking closely at the photos you can see the cracks in the shank and the burn on the rim. All of the other items come through in the photos as well.

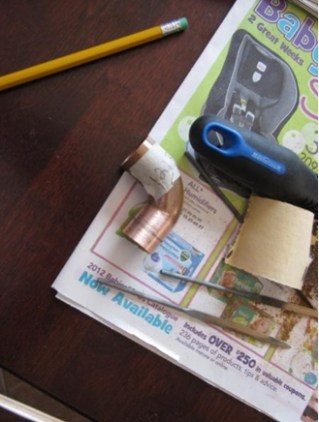

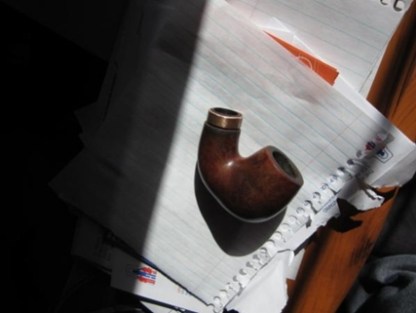

I began the process by reaming out the bowl and then shaping a nickel band into a diamond and pressure fitting it on to the shank. I also then used a small hammer to tap the band into shape around the shank and square off the edges. The next four pictures show the band after it has been shaped and pressure fit into place. The final picture of the four shows the end view of the shank with the band in place.

I decided to top the bowl to remove the damage of the burn and smooth out the rim edge. The burn was not very deep but it was a small trough in the rim that went from edge to edge. The inner edge of the bowl was also damaged by burning. I use a piece of medium grit emery cloth to begin with. I put it on a flat board on my work table and then sand the bowl rim in a clockwise circle until I have removed all of the damage. I follow up the emery cloth with 320 grit sandpaper used in the same manner. I finish the rim with a fine grit sanding sponge. The next four photos show the process and the progress of the topping procedure. In the second photo you can clearly see the damage from the burn. The third and fourth photos show the rim after it is smoothed out and the burn damage is minimized. I did not take pictures of the sanding process with the 3230 grit and sanding sponge as they followed the same format as that of the emery cloth.

After topping the bowl and finishing the rim sanding with micromesh sanding pads in 1500-3200 grit I stained the bowl with an oxblood stain. I restained the entire bowl in order to get a match between the bowl and the rim. The next photos show the stained bowl. At this point in the process I still needed to buff the bowl but I decided to set it aside to dry while I worked on the stem to remove the oxidation and tooth chatter. I began by wet sanding the stem with a 1500 grit micromesh sanding pad. I keep a bowl of water at hand so that I can dip the sanding pad in the water and also clean it between sandings. The next four photos show the stem after sanding it with the 1500 grit pads.

I polished the stem with Maguiar’s Scratch X2.0 after the 1500 grit sanding. I then wet sanded the stem with 1800 and 2400 grit micromesh sanding pads. The next three photos picture that process and the progress on the stem.

I continued sanding with the micromesh pads. I dry sanded with 3200, 3600 and 4000 grit pads. I worked on the inside of the saddle with a folded pad to get the angles correct and clean up that area. I also scrubbed around the button and the edges of the button, working to keep the edges sharp and defined. The next three photos show that progress.

I scrubbed the stem once again with the Maguiar’s and wiped it off repeatedly with a cotton pad. I continued to dry sand the stem with 6000, 8000, 12,000 grit micromesh. Once I had finished the sanding I buffed the stem and pipe with White Diamond on my buffer to shine both. I took the pipe back to my bench and gave the stem a coat of Obsidian Oil. I rubbed it into the stem and then gave the bowl a coat of Halcyon II wax and hand buffed it with a cotton cloth and then gave the rim and stem several coats of carnauba wax. Once I was finished I took it to the buffer once again and gave it a buff with a clean flannel buffing pad. The finished pipe can be seen in the photos below.