Blog by Steve Laug

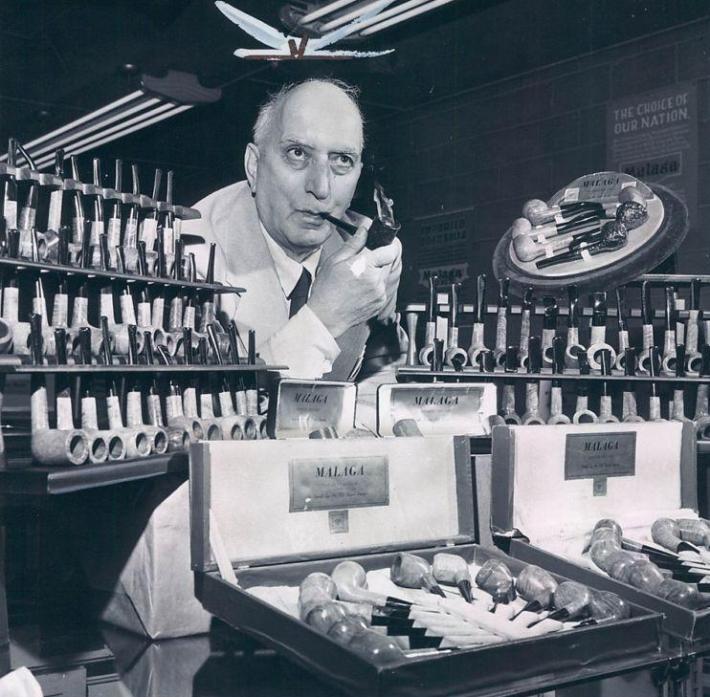

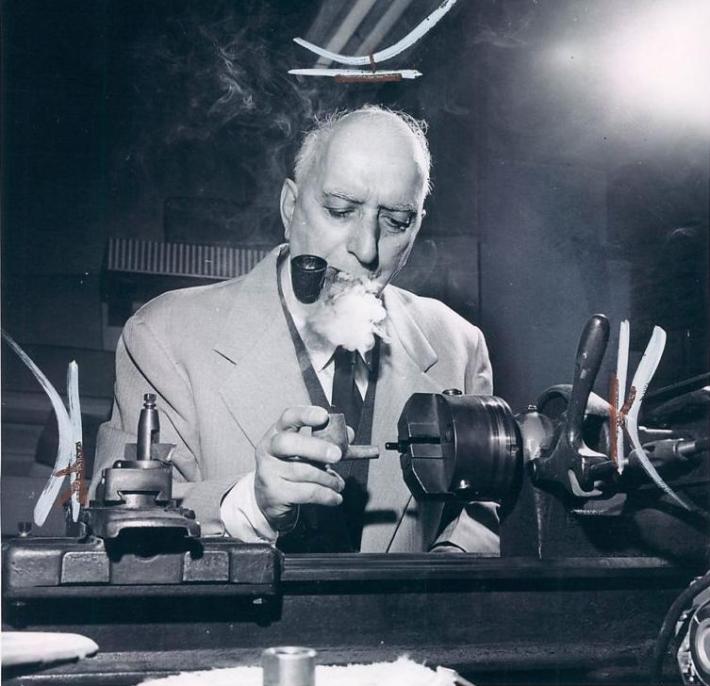

My brother Jeff found this Malaga pipe on Ebay recently and bought it. He sent it up to Vancouver for me to work on. It was the next one that I chose to clean up. I needed a bit of a break after the work on the Ardor Urano Fantasy that I just finished. As I went through my bin of pipes to refurbish the grain on this one called out to me. It was in decent shape so it would not take a lot to bring it back to life. The finish was dirty and had some stickiness to the sides of the bowl and shank. The stem would not seat all the way in the shank and was very hard to turn. The bowl had a thin cake and the rim had some slight lava on the surface. It appeared to have some dents in it as well but after it was cleaned I would be better able to tell. The stamping on it is simply Malaga on the left side of the shank. I have written about Malaga pipes and their maker, George Khoubesser on a previous blog post https://rebornpipes.com/2013/02/09/george-khoubesser-and-malaga-pipes/

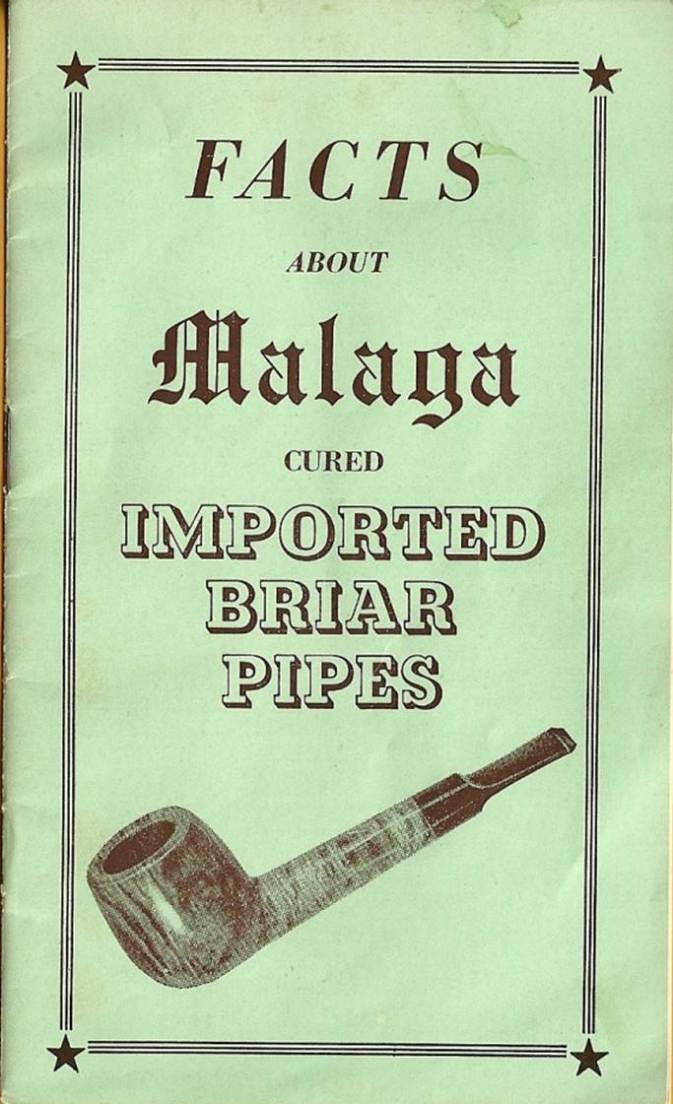

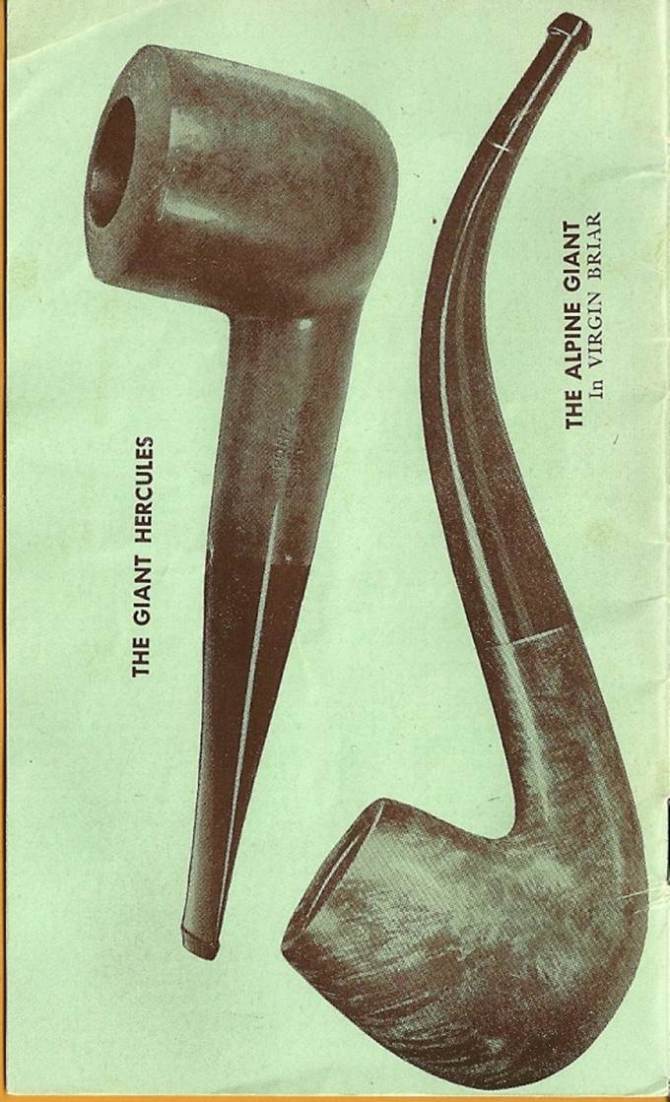

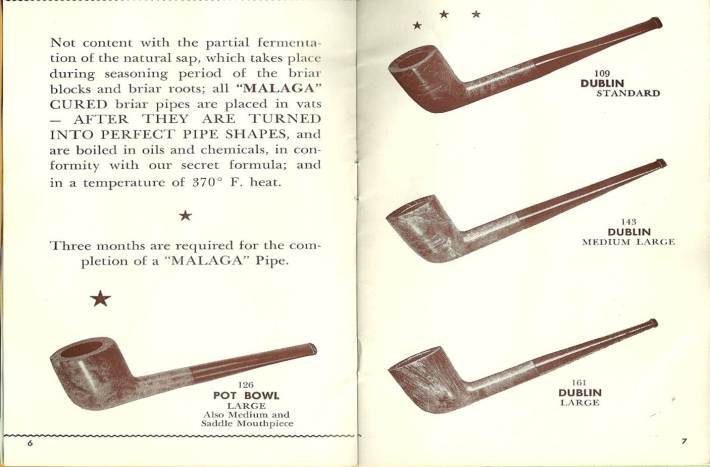

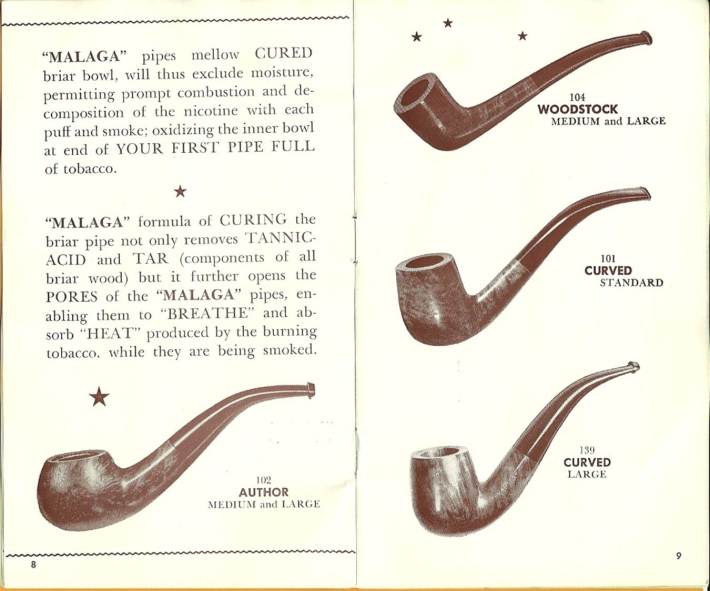

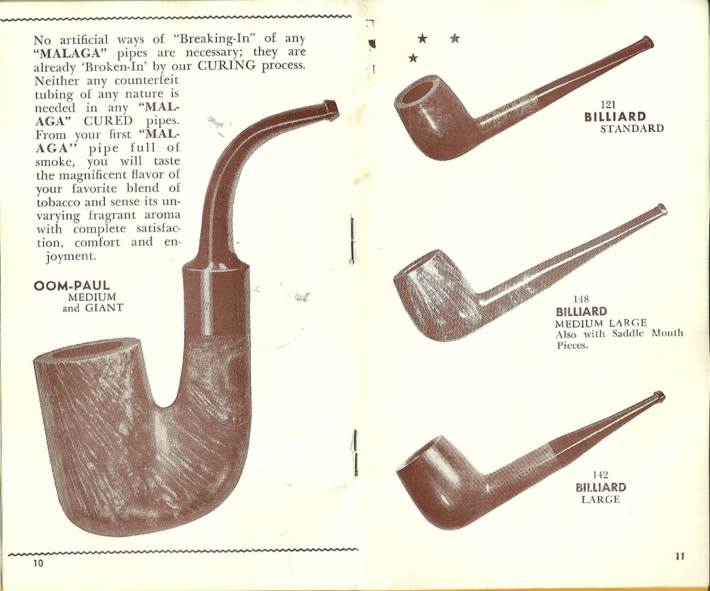

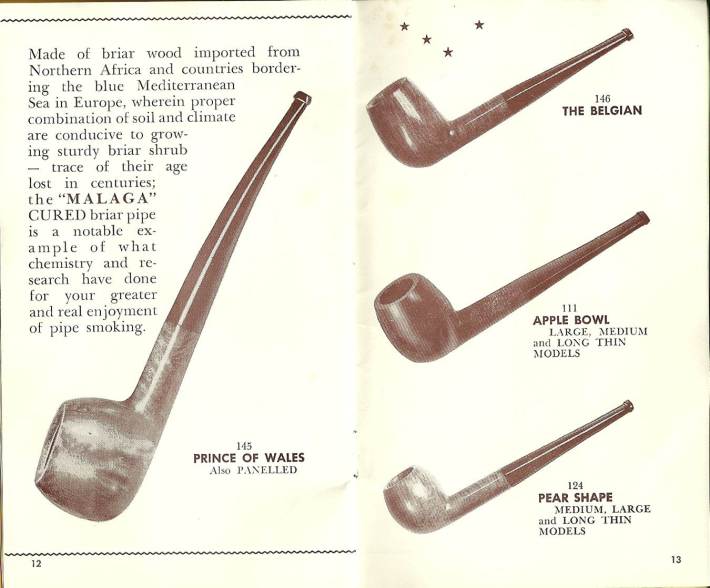

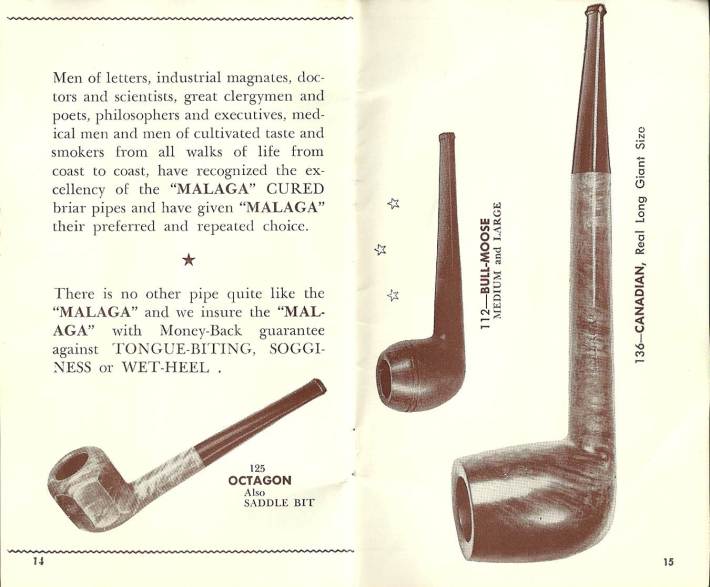

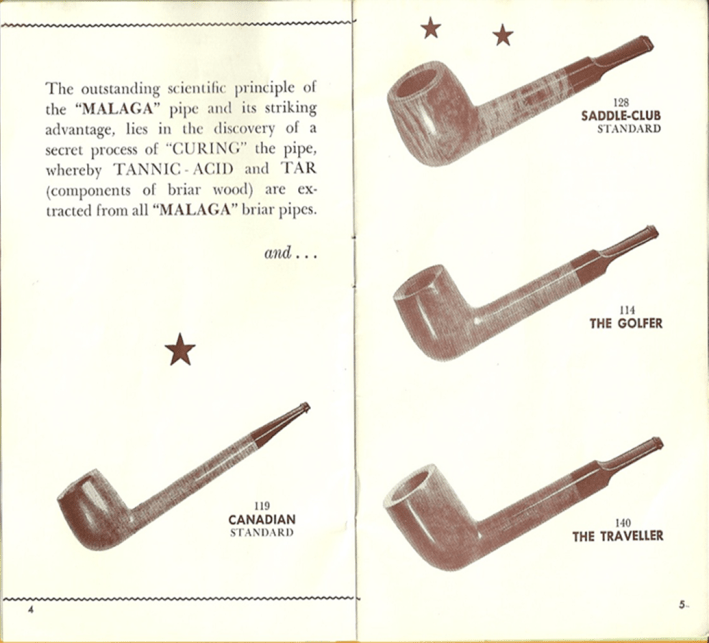

In the Malaga catalogue that I have on the blog this shape is called a Saddle Club and is shape number 128. There is no shape number on this pipe.

The stem had some light oxidation and some calcium buildup at the button. There was some tooth chatter on the top and bottom sides of the stem. The button was interesting to me. It was rounded toward the slot on both the top and the bottom sides like an older style orific button. It had a slot rather than a single hole in the end of the button. It was not worn and there were no dents or marks in the button.

The stem had some light oxidation and some calcium buildup at the button. There was some tooth chatter on the top and bottom sides of the stem. The button was interesting to me. It was rounded toward the slot on both the top and the bottom sides like an older style orific button. It had a slot rather than a single hole in the end of the button. It was not worn and there were no dents or marks in the button.

I carefully removed the stem from the shank as I did not want to either split the shank or damage the tenon. Once I had it out of the shank I cleaned the mortise and airway with pipe cleaners, cotton swabs and alcohol. I also cleaned the airway on the stem.

I carefully removed the stem from the shank as I did not want to either split the shank or damage the tenon. Once I had it out of the shank I cleaned the mortise and airway with pipe cleaners, cotton swabs and alcohol. I also cleaned the airway on the stem.

With the mortise clean I was able to easily twist the stem into the shank. I scrubbed the surface of the bowl with Murphy’s Oil Soap to remove the stickiness and general grime on the surface of the pipe and then rinsed it under running water. I dried it off for the photos below.

With the mortise clean I was able to easily twist the stem into the shank. I scrubbed the surface of the bowl with Murphy’s Oil Soap to remove the stickiness and general grime on the surface of the pipe and then rinsed it under running water. I dried it off for the photos below.

I reamed the pipe with the PipNet reamer and took the cake back to bare briar.

I reamed the pipe with the PipNet reamer and took the cake back to bare briar. With the bowl reamed I worked on the rim of the pipe. I scrubbed it with cotton pads and the oil soap and then used a 1500 grit micromesh pad to remove the buildup. I wet sanded the rim with the micromesh pad until the surface was clean and smooth. The photo below shows the rim after cleaning. The small dings are virtually invisible and the crowned rim looks really good.

With the bowl reamed I worked on the rim of the pipe. I scrubbed it with cotton pads and the oil soap and then used a 1500 grit micromesh pad to remove the buildup. I wet sanded the rim with the micromesh pad until the surface was clean and smooth. The photo below shows the rim after cleaning. The small dings are virtually invisible and the crowned rim looks really good. I sanded the stem with 220 grit sandpaper to remove the tooth chatter and the light oxidation. I rubbed it down with Obsidian Oil afterwards and set it aside.

I sanded the stem with 220 grit sandpaper to remove the tooth chatter and the light oxidation. I rubbed it down with Obsidian Oil afterwards and set it aside. I wet sanded the stem with 1500-2400 grit micromesh sanding pads and then rubbed the stem down with Obsidian Oil. I dry sanded it with 3200-4000 grit pads and gave it another coat of oil. I finished sanding the stem with 6000-12000 grit pads and gave it a final coat of oil. I set it aside to dry.

I wet sanded the stem with 1500-2400 grit micromesh sanding pads and then rubbed the stem down with Obsidian Oil. I dry sanded it with 3200-4000 grit pads and gave it another coat of oil. I finished sanding the stem with 6000-12000 grit pads and gave it a final coat of oil. I set it aside to dry.

I buffed the pipe with Blue Diamond and then gave bowl and several coats of carnauba wax. The finished pipe is shown in the photos below. The crowned rim and the grain on this old pipe are stunning. It is a solid piece of briar with no fills or flaws. The bowl is quite large for a Lovat – length is 5 ½ inches, height is 2 inches, and the diameter of bowl is 7/8 inches. The anonymous pipemaker who made it for Malaga chose a stunning piece of briar and laid the pipe out so well that is showcases the grain. All I can tell you is it looks even more stunning in person than it does in the photos. Thanks for looking.

I buffed the pipe with Blue Diamond and then gave bowl and several coats of carnauba wax. The finished pipe is shown in the photos below. The crowned rim and the grain on this old pipe are stunning. It is a solid piece of briar with no fills or flaws. The bowl is quite large for a Lovat – length is 5 ½ inches, height is 2 inches, and the diameter of bowl is 7/8 inches. The anonymous pipemaker who made it for Malaga chose a stunning piece of briar and laid the pipe out so well that is showcases the grain. All I can tell you is it looks even more stunning in person than it does in the photos. Thanks for looking.