Blog by Steve Laug

I am often asked by other hobbyist pipe refurbishers how I go about re-staining the pipes that I refurbish. I have answered the question in different ways over the years as I have worked out my own process. This past weekend I had some time and a box of pipes to work on so I decided to document the process I use. I took photos of four old pipes that I was reworking; these photos take you through my methods from start to finish. I have added written commentary to explain what I have done. The method I describe is how I work with estate bowls like these. I am certain that there are other methods that can be used with equal success. This is the one I have arrived at over the past ten years as I have been reworking estate pipes. I am sure that it will continue to evolve in the years ahead as it has over the past years. Here it is for your perusal and use. Feel free to use it, enjoy the process of rejuvenating the finish of an old pipe, adapt it and modify it as you will. Email your modifications and additions to the method to as we work to keep the fire alive in the home based pipe restoring hobby – slaug@uniserve.com.

I need to make a final confession before I jump ahead to describe and document the process. I totally forgot to take pictures of the state these old pipes were in when I received them. As is often the case for me, the cleaning process took on a life of its own and once it is moving along I find it hard to slow it down. So, with that out of the way, I begin with pictures of the pipes after I removed them from an hour soak in an alcohol bath.

Out of the alcohol bath

Once I have chosen the pipes to restore I remove the stems and place them in a soak of Oxyclean and water while I work on the bowls. I place the bowls in an alcohol bath. I use a plastic jar with a screw on lid to hold the 99% isopropyl alcohol for the bath. It is roughly a large mouthed quart sized jar and will hold four bowls. The size also allows me to reach in and retrieve them when they are finished. I reuse the alcohol in the bath for a long time. I find that it turns dark from the stains and the sediment settles to the bottom of the jar. I pour off the alcohol regularly and wash the jar so that there is no sediment remaining. I also top up the jar with fresh alcohol to keep the levels high enough to cover the bowls.

The first two pictures below show the four bowls after they have been removed from the bath and have been dried. (In each photo the bowls will be in the same order for ease of recognition.) Starting at the top left and working left to right you will see the effects of alcohol bath in removing finish. I have found that it does not remove all the stain but it removes the finish, waxes and oils that are over the stain. When the bowls are removed they have a flat finish look to them. The top left bowl has a slightly yellow stain once the varnish coat was removed. The top right bowl has a reddish stain that was also under a coat of varnish. The bottom left is a prehistoric GBD finish/sand blast with a dark red/brown stain. The pipe on the bottom right has a dark brown stain and had a coat of shellac or varnish over it. The varnish on the last pipe had turned milky white even before I put it in the bath and increased when I took it out of the alcohol bath. The fourth bowl will take the most work to remove the finish. All will need more hand work with an alcohol soaked soft cloth and a soft bristle tooth brush to remove the residual finish. The smooth bowls will be sanded and further cleaned.

Washed and sanded

The pictures below show the bowls after they have been washed in alcohol and sanded and rewashed and re-sanded repeatedly. The stain colour is removed as much as it will be at this point in the process. There is still a lot of work to do on each bowl before staining can be done. The top coat of varnish, wax and the grit and grime have all been removed at this point. From the pictures you can see that there is still some varnish on the bottom right pipe but the majority has been removed and the others are getting ready to go to the next step in the process. Once I finished this stage of sanding I washed them a final time with a tack (soft cotton material) cloth to remove dust and such and also let me see any remaining shiny spots on the finish.

Two of my favourite tools are shown in the following pictures (I use both constantly in the process of refurbishing and always have them near at hand) – a tooth brush and a dental pick. The dental pick allows me access to the rings on the bulldogs. I carefully use it to follow the rings around the bulldogs and clean out the grit that gets stuck in them. I follow that up with the tooth brush which allows me to rub the alcohol into the rings and to scrub other places in the blast on the prehistoric and stubborn shiny spots on the smooth pipes. They both are used in cleaning rims and the dental pick also precedes my pipe cleaners in the shank. I have straightened one end to make access to the shank easier. These pictures show the bowls after the third sanding and alcohol wash. I also sand the rims with 400, 600 and then finally with 1200 to remove any grit or rough spots on the finish. All the bowls have been sanded with 1200 grit sand paper. I sand them one more time with the 1200 grit sandpaper and then I use micromesh pads to get a good smooth surface on the bowl. If you choose to go for a scratch-free finish you can examine the bowls with a jewellers loop under a bright light and re-sand as necessary to remove any noted scratches. For the majority of the old timers that I refurbish, I sand until they are scratch free to the naked eye in a bright light. To my mind some of the deeper nicks and such lend character to the old pipe and contribute to the look of age. My main requirement is that they are smokeable when I am finished and that they look good for their age. Should you choose to go further with the finish the choice is yours as you re-work them.

The next picture shows the foursome after all the smooth pipe bowls and smooth rim on the sand blast have been sanded with 1800/2400/4000 micromesh pads. They are smooth to the touch and have a rich shine to them. This is a good time to give them an inspection for any marks or scratches that you want deal with further. After I inspect them this last time, I wipe them down with an alcohol damp cloth to get any residual grit or dust off the bowls and set them aside. The bowls are ready to be re-stained.

Re-staining the bowl

In preparation for staining each pipe bowl, I insert folded pipe cleaners in the shanks to enable me to manipulate them with ease while I am applying the stain. This gives me some flexibility in turning the bowl at different angles to apply the stain coat. You will note the Fiebing’s stain in the previous picture – that is the stain I use. It comes in a variety of colours and is an aniline (alcohol based) stain. It works extremely well on wood. All of these bowls were given a first coat of Fiebing’s Dark Brown stain applied heavily. While it is still wet I use a match to light the stain to set it in the grain. It does not light the bowl on fire at all but only burns off the alcohol in the stain coat. For these four bowls, I started with the blast and liberally applied the stain to the bowl. I start with the bowl held bottom up and let the stain flow toward the tops. I follow the flow of the stain to ensure that I have thoroughly and evenly covered the entire bowl surface. I finish the first coat using the dauber pictured in the lid below to stain the rim. I reapply the stain to make sure the coat is even and not streaked.

The picture below was taken after the second application and flaming of the stain. After the first coat of stain is dry to touch, I give each bowl a second coat of stain and set it aflame with a match or lighter. After flaming the stain the bowls are basically dry to the touch and I set them aside until they are thoroughly dry. (I often let the bowls sit over night to dry.) The next day (or later the same evening if I get impatient or curious) I take them to my buffers and see what they will look like with a light touch on the buffing wheel. I generally use the Tripoli buff with a light touch, though I have also used the White Diamond buff as well. For those who do not have a buffer I have also sanded the bowls at this point with 1200 grit sand paper or higher. If the stain is too dark to my liking I wipe the bowls with an alcohol damp cloth until I get the colour the way I want it on each pipe. That is one of the beauties of aniline stain! The briar in each pipe bowl will make them quite unique looking once the stain is buffed.

While the bowls are drying I turn to work on the stems. Throughout the process described above, the stems have been soaking in an OxyClean bath. I put a mixture of once scoop of OxyClean into a one quart plastic covered jar and mix it with hot tap water. I shake it until the powder is all dissolved and the liquid is a milky white. Then I place the stems in the bath to soak. Generally I soak them a minimum of two hours but often will leave them in the wash over night. They remain in the bath the entire time I am working on the bowls.

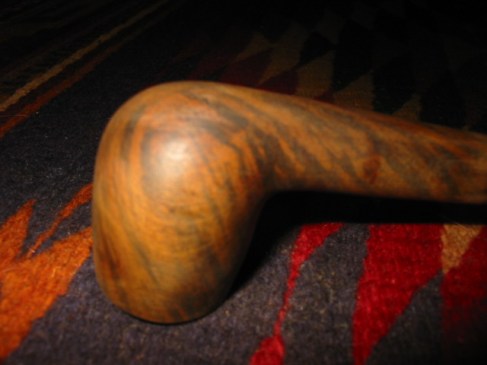

With this foursome I grew impatient and was curious to see the finished product once I buffed the stain off the bowls. The bowls were dry so I took them to the buffer. The following pictures show the bowls – stained, buffed and polished. At this point in the process, I still need to wax them with carnauba but the pictures give you the idea of what they look like. Each pipe bowl took the dark brown stain in its own way. To me one of the joys of the process is arriving at this step and seeing the freshly stained bowls. I love the contrasting colours and grain that comes through in the pipes.

The final pictures in this essay show the finished product using two of the pipes. I finished working on the stems while the stain was drying. They are both WDC pipes. The apple is an Aristocrat shape 11. The bulldog is a Royal Demuth shape 79. Both are screw mount stems with interesting diffusing apparatus in them.