Blog by Steve Laug

I am finally down to the last five pipes in my refurbishing box. I have a bunch more on their way here but I would like to finish up this lot before they arrive as they have been sitting here for a long time always getting passed over and laid aside for more favorable looking options. Last evening I decided to rework this old Dr. Grabow Riviera. It was a pleasant shape but an ugly piece of briar. I removed the stem and was amazed that it was a push stem with a well made tenon. The drilling was spot on and the internals were really well done. The draught on the pipe was excellent. The bowl was clean and the drilling in the bowl was nicely done as well with the airway perfectly centered on the back bottom edge of the bowl. The externals however left much to be desired. The first series of four pictures below show the bowl with the many fills that are on the outside of the bowl. These were not tiny fills by any means; in fact the majority of them are quite large. I had to make a decision on whether to refill them or to rusticate the pipe. Last evening I just was not in the mood to rusticate the pipe. Sometimes I just feel like working over a bowl but this was not the night for doing that. So I decided to pick out the fills and rework them with briar dust and superglue and restain the pipe. The stem was in pretty decent shape also – no bite marks or tooth chatter, very clean with a minimum of oxidation.

The next series of four photos show the bowl after I have picked out the fills with my dental pick. I actually have a good time picking out the ugly pink putty or as in this case bright white putty. The holes that were filled were not deep but they were on the larger side. Once I picked out the putty I wiped down the bowl with acetone to clean up the mess. I always try to scrunch the cotton pad down into the hole to draw out the last of the putty dust. The worst fill to work with was the one on the back side rim. It was like a saw cut in the rim. It was quite deep and intrusive going from the outside to the inside of the bowl.

With each of the cleaned out holes I used my dental pick to tamp in briar dust. I try to tamp in the dust until the hole is packed and the dust forms a bit of a bulge on the hole. I find that once I drip in the superglue the dust settles in and the new fill is closes to the surface of the bowl. I also purposely overfill so that I can work to smooth out the fill with sandpaper and blend it into the surface of the bowl. The next three pictures show the patches on the bowl. You will notice the overflow of superglue on the surface of the bowl in the pictures below. This is fairly easily removed as it dries quickly and does not permeate the surface of the bowl.

The next series of thirteen photos show the progress of sanding the patches back to the surface of the bowl. In this case I was planning on refinishing the bowl anyway so I sanded the whole bowl back to bare briar. I began by sanding the patches with 240 grit sandpaper and then 320 grit sandpaper. Once the overfill of briar dust and glue was sanded fairly smooth I sanded itwith a medium grit sanding sponge and then a fine grit sanding sponge. I wanted to get rid of the excess fill and also to remove all the scratches in the surface of the bowl. I wet sanded the bowl after this with 1500 and 1800 grit micromesh to ready it for staining. I wiped it down with acetone on a cotton pad. The final pictures show the pipe as it is ready for restaining. You can see that the white putty fills are now dark patches on the bowl. I find that those these dark patches still show up they are easier to blend into the stain and somehow do not seem as intrusive to my eyes as the white patches.

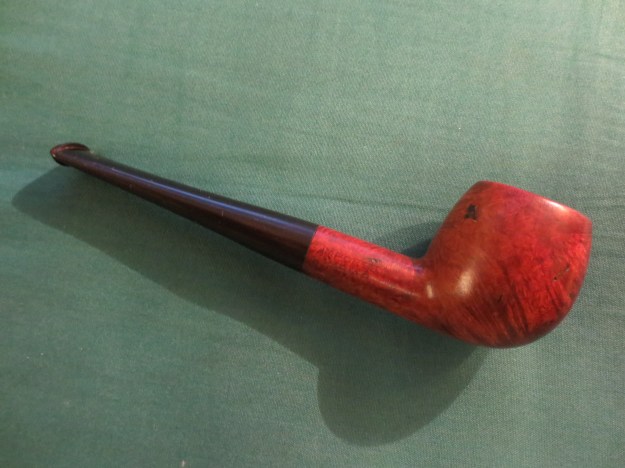

I decided to stain the pipe with an oxblood aniline stain. I applied it with a cotton swab, flamed it, restained and reflamed it. Once it was dry I hand buffed it with a soft cotton cloth before taking it to the buffer. The next four photos show the pipe after the staining and initial hand buff.

After staining the bowl I worked on the stem. I sanded it with a fine grit sanding sponge and then worked through the micromesh sanding pads from 1500-12,000 grit. I wet sanded with the first three grits (1500, 1800 and 2400 grit) and then dry sanded with the remaining grits. I took it to the buffer and buffed the stem and bowl with White Diamond before applying several coats of carnauba wax and then buffing with a soft flannel buff. The next series of four photos show the finished pipe. In my opinion the fills look far better than when I first started on the pipe. They now are tolerable in my sight and I believe this will make a fine yard pipe or rotation extender for some new pipe smoker. It is cleaned and ready to smoke.