Blog by Steve Laug

I have a growing box of bowls that came to me without stems. It seems each time I clean it out and restem the pipes I inherit more of them. This is not a complaint as I actually enjoy restemming pipe bowls. It is always a challenge to get a new stem to align properly with the shank and to deal with cracks or damages to the bowl or the shank. This bowl came to me and I immediately fell for the rustic rocklike features of the rustication. It was gnarled and rough looking and felt great in the hand. The bowl was dirty and the deep grooves of the rustication had a lot of dirt and grime build up in them. The rim was caked and the rustication pretty much filled in the grooves making the rim surface smooth. The bowl had a rough cake in it and looked as if someone had started reaming the bowl but did not finish. There were some small fissures like cracks in the sides of the bowl near the entrance of the airway and on the bottom and the top of the airway. Someone had cleaned out the shank so it was not too dirty. There was a small crack on the top of the shank that was about 1/8 long. I could open it slightly with a wedge so it would need to be glued and banded. The pipe showed a lot of promise though and I could see it come alive if I had the correct stem for it.

In the photo below there is a small crack barely visible in the middle of the shank end between my fingers. I have circled it with red to focus your eye on it. The tip of the red arrow is on top of the crack in the shank. It extends about 1/8 to ¼ inch.

In the photo below there is a small crack barely visible in the middle of the shank end between my fingers. I have circled it with red to focus your eye on it. The tip of the red arrow is on top of the crack in the shank. It extends about 1/8 to ¼ inch.

I took a close-up photo of the bowl and rim to give you an idea of the state of things when I started. It is hard to see but at this point I could see some small cracks around the entrance of the airway to the bowl.

I took a close-up photo of the bowl and rim to give you an idea of the state of things when I started. It is hard to see but at this point I could see some small cracks around the entrance of the airway to the bowl. I went through my can of stems and found a green acrylic stem that would do the trick on this pipe. It would go well with the rustication and the length and width of the stem would carry through the thickness of the bowl. I sanded the tenon with the Dremel and sanding drum until it was a close fit to the shank. I finished sanding by hand with 220 grit sandpaper. It fit well in terms of the width of the shank but it was slightly thicker on the top and the bottom where it met the shank. I was careful inserting it as I did not want to crack the shank further.

I went through my can of stems and found a green acrylic stem that would do the trick on this pipe. It would go well with the rustication and the length and width of the stem would carry through the thickness of the bowl. I sanded the tenon with the Dremel and sanding drum until it was a close fit to the shank. I finished sanding by hand with 220 grit sandpaper. It fit well in terms of the width of the shank but it was slightly thicker on the top and the bottom where it met the shank. I was careful inserting it as I did not want to crack the shank further.

I used the Dremel and sanding drum to remove much of the excess thickness on the top and the bottom of the stem at the shank junction. I do this carefully with the stem in place in the shank so that I can get it as close as possible without damaging the finish on the shank. You can see in the next two photos that the junction is pretty smooth now and the thickness is almost a match.

I used the Dremel and sanding drum to remove much of the excess thickness on the top and the bottom of the stem at the shank junction. I do this carefully with the stem in place in the shank so that I can get it as close as possible without damaging the finish on the shank. You can see in the next two photos that the junction is pretty smooth now and the thickness is almost a match.

I finished the fit with a file and took off the remaining thickness that had to go. I also used the file to remove the tooth indentations on both sides of the stem near the button.

I finished the fit with a file and took off the remaining thickness that had to go. I also used the file to remove the tooth indentations on both sides of the stem near the button.

With the fit nearly perfect it was time to sand out the filing marks and smooth out the stem. I have a medium grit sanding stick that works perfect for this application and I sanded with it until all of the file marks were gone and the transition between the shank and the stem was smooth.

With the fit nearly perfect it was time to sand out the filing marks and smooth out the stem. I have a medium grit sanding stick that works perfect for this application and I sanded with it until all of the file marks were gone and the transition between the shank and the stem was smooth.

With the stem fit roughed in I turned my attention to the bowl and shank. I wanted to have the shank and bowl clean so I could deal with the repairs to the airway in the bowl and the crack on the top of the shank. I reamed the bowl with a PipNet reamer using the largest cutting head. I cleaned up the remaining cake with the Savinelli Pipe Knife.

With the stem fit roughed in I turned my attention to the bowl and shank. I wanted to have the shank and bowl clean so I could deal with the repairs to the airway in the bowl and the crack on the top of the shank. I reamed the bowl with a PipNet reamer using the largest cutting head. I cleaned up the remaining cake with the Savinelli Pipe Knife.

I scrubbed the exterior of the bowl with Murphy’s Oil Soap and a tooth brush on the sides, shank and the bowl of the bowl. I scrubbed the rim with a brass bristle brush until all of the lava that filled the rustication was gone.

I scrubbed the exterior of the bowl with Murphy’s Oil Soap and a tooth brush on the sides, shank and the bowl of the bowl. I scrubbed the rim with a brass bristle brush until all of the lava that filled the rustication was gone. I rinsed off the soap with warm water and dried the bowl with a soft towel. The cleaned and reamed pipe is shown in the photo below.

I rinsed off the soap with warm water and dried the bowl with a soft towel. The cleaned and reamed pipe is shown in the photo below. With the bowl reamed and the finish clean I turned to the internals. I cleaned out the mortise and airway into the bowl with pipe cleaners, cotton swabs and alcohol. It did not take too much to clean out the pipe. I cleaned the stem the same way and used a dental pick to clean up the slot in the end of the button.

With the bowl reamed and the finish clean I turned to the internals. I cleaned out the mortise and airway into the bowl with pipe cleaners, cotton swabs and alcohol. It did not take too much to clean out the pipe. I cleaned the stem the same way and used a dental pick to clean up the slot in the end of the button.

I lightly sanded the crack on the top of the shank and spread it open with a dental pick. I used a tooth pick to push super glue into the crack and then held the crack together until the glue set. Once it was dry I found a round band that had the right circumference to fit the shank and heated it with a lighter and pressed it onto the shank of the pipe.

I lightly sanded the crack on the top of the shank and spread it open with a dental pick. I used a tooth pick to push super glue into the crack and then held the crack together until the glue set. Once it was dry I found a round band that had the right circumference to fit the shank and heated it with a lighter and pressed it onto the shank of the pipe.

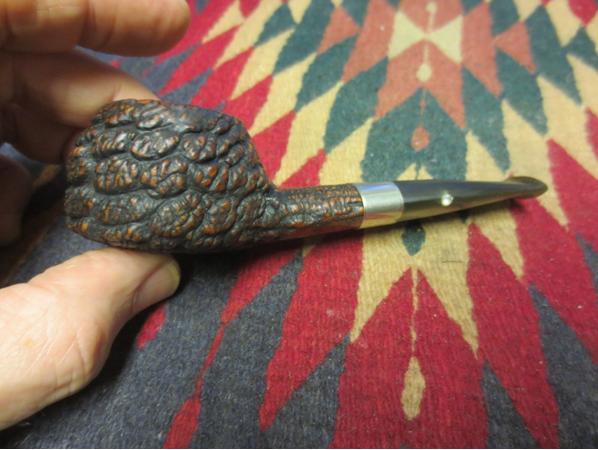

With shank repair complete and the bowl cleaned and ready I put the stem in place in the shank and took some photos of the pipe. I really liked the look of the band breaking up the rustic bowl and the smooth green stem. The band fit perfectly and did not cover the stamping on the underside of the shank. I still needed to sand the stem some more to get a shine but you can see what the pipe will look like at this point.

With shank repair complete and the bowl cleaned and ready I put the stem in place in the shank and took some photos of the pipe. I really liked the look of the band breaking up the rustic bowl and the smooth green stem. The band fit perfectly and did not cover the stamping on the underside of the shank. I still needed to sand the stem some more to get a shine but you can see what the pipe will look like at this point.

I mixed a batch of pipe mud (cigar ash and water) and used a dental spatula to apply it to the bottom of the bowl. I inserted a pipe cleaner in the airway and used the spatula to apply the mud to the small cracks and fissures around the airway. Once the mud cured the pipe bowl would be in good shape until a new cake was built.

I mixed a batch of pipe mud (cigar ash and water) and used a dental spatula to apply it to the bottom of the bowl. I inserted a pipe cleaner in the airway and used the spatula to apply the mud to the small cracks and fissures around the airway. Once the mud cured the pipe bowl would be in good shape until a new cake was built. I heated the stem in a cup of water in the microwave until it was pliable and then put a gentle bend in it to give it a more elegant look and comfortable feel.

I heated the stem in a cup of water in the microwave until it was pliable and then put a gentle bend in it to give it a more elegant look and comfortable feel.

I wet sanded the stem with 1500-2400 grit micromesh sanding pads to remove the scratches. I dry sanded with 3200-4000 grit pads and then finished with 6000-12000 grit pads. I rubbed away the sanding dust with a damp cloth.

I wet sanded the stem with 1500-2400 grit micromesh sanding pads to remove the scratches. I dry sanded with 3200-4000 grit pads and then finished with 6000-12000 grit pads. I rubbed away the sanding dust with a damp cloth.

I gave the pipe a light buff with Blue Diamond on the wheel to bring some deep shine to the stem. I then gave the stem several coats of carnauba wax and buffed it with a clean buffing pad. I finished by hand buffing it with a microfibre cloth. The finished pipe is shown in the photos below. The green acrylic stem works well with the rough finish on the bowl. I like the finished look. What do think? Thanks for looking.

I gave the pipe a light buff with Blue Diamond on the wheel to bring some deep shine to the stem. I then gave the stem several coats of carnauba wax and buffed it with a clean buffing pad. I finished by hand buffing it with a microfibre cloth. The finished pipe is shown in the photos below. The green acrylic stem works well with the rough finish on the bowl. I like the finished look. What do think? Thanks for looking.