by Steve Laug

Just before the Postal Strike here in Canada I received an email from Baker regarding a Tinsky American Smoking Pipe that he had purchased that needed some attention. He sent me a link in the email to a series of photos showing the issues with the pipe.

Hey Steve…

I got an American Smoking Pipe bent Dublin from the 80’s several months ago and just noticed a big crack opening up in the bottom of the bowl….

This pipe also has a dry, desiccated look and feel to it — almost like a piece of driftwood. What do you think? Is this something you can help with? I’m not in a rush but it’s too good a pipe to let fade away.

Best regards, Baker

I have included the photos that Baker sent me below. It truly is a dry looking sandblast pipe with some issues of cracks and flaws in the briar. The first photo gives a profile of the pipe. He also took photos of the rim top and bowl. You can see from the photos that the bowl has a moderate cake. It does not appear that there are cracks on the inside of the bowl in the photos. There is some darkening around the inner edge. The rim top has some beautiful and rich grain.

He also took photos of the rim top and bowl. You can see from the photos that the bowl has a moderate cake. It does not appear that there are cracks on the inside of the bowl in the photos. There is some darkening around the inner edge. The rim top has some beautiful and rich grain.

He took several photos of the crack in the bowl radiating from a flaw in the briar. It is on the front of the heel.

He took several photos of the crack in the bowl radiating from a flaw in the briar. It is on the front of the heel.

There was also a large flaw on the lower front of the bowl. He included a photo of that as well.

There was also a large flaw on the lower front of the bowl. He included a photo of that as well. He also included a photo of the stamping on the underside of the shank. It reads American in an oval [over] REG. NO. [over] C 486/*S 5. It is clear and readable.

He also included a photo of the stamping on the underside of the shank. It reads American in an oval [over] REG. NO. [over] C 486/*S 5. It is clear and readable.  I have collected and smoked Mark Tinsky’s pipes for over 30 years now and thoroughly enjoy them. I cannot speak highly enough about the quality and craftsmanship of his pipes. I have pipes made by Mark and by Curt Rollar in my collection and both are great smokers and pipes that reach for regularly in my choice of pipes. I turned to his website for a quick summary of the history of the brand (http://www.amsmoke.com/Index%20Folder/PipeHist.html). I quote from the site as it is a short, concise history.

I have collected and smoked Mark Tinsky’s pipes for over 30 years now and thoroughly enjoy them. I cannot speak highly enough about the quality and craftsmanship of his pipes. I have pipes made by Mark and by Curt Rollar in my collection and both are great smokers and pipes that reach for regularly in my choice of pipes. I turned to his website for a quick summary of the history of the brand (http://www.amsmoke.com/Index%20Folder/PipeHist.html). I quote from the site as it is a short, concise history.

The American Smoking Pipe Co. was formed in 1978 by Mark Tinsky and Curt Rollar. Both started making pipes for Jack Weinberger (JHW Pipes) while in high school and throughout college. Determined to blaze their own path, they formed their own company- its goal to create unique pipes, lightweight and comfortable, where attention to detail was the rule not the exception. Exulting in their new freedom, they carved out new shapes that were balanced between the radical freehand era of the 70’s and the board pipe look of other conservative companies. Hungry for recognition, they stormed the Eastern and Southern shops looking for markets to sell their pipes. Many hidebound retailers refused to try something new, preferring to sell, well, what has always sold before. However, their pipes did take root in many shops and the business thrived.

They continued expanding their pipe making capabilities, adding employees to help finish the pipes. In 1990, over a disagreement over how much to expand, Curt Rollar left the company. This put a break on expansion and coupled with a U.S. recession and rising anti-smoking fervour served to limit production to supplying existing retailers, thus ending a decade of growth. With pipes sales in decline, we turned to pipe repair as a way to supplement revenues. Finding that we liked fixing things, American concentrated on pipe repair. While working hard at repair and manufacture American is ready once again to expand its markets through its existing network of shops serviced by pipe repair.

The pipe I am working on is stamped American in an oval with a Reg. No. [over] C 486/*S 5 as noted above. The stamp tells me that the pipe was made in April of 1986. The S stamp could signify that the pipe is a sandblast but I am not sure. The 5 is the size of the pipe.

We chatted and he prepared to send the pipe to me. THEN THE CANADA POSTAL STRIKE HAPPENED. I had an idea of shipping it to a mailbox in the US and then I could get it from there rather than wait for the strike to end. Baker shipped it and it arrived quite quickly. Sadly, I was ill as was Kenneth so we were not able to head south to pick up the pipe. Kenneth picked it up and dropped it off Friday.

I took photos of the pipe before I started my work on it. It was dry and desiccated on the outside as Baker noted. There was a moderate cake in the bowl and some darkening on the rim edge. The crack and flaws are very visible in the photos. The blast seemed almost worn and tired. The variegated brown acrylic stem looked good with a few tooth marks and chatter on both the top and underside of the pipe. Have a look.

I took a photo of the bowl and rim top to show the condition of both. The rim top is smooth and has some beautiful birdseye grain. You can see the debris in the bowl and darkening on the inner edge. I also took photos of the acrylic stem showing the tooth marks and chatter on both sides ahead of the button.

I took a photo of the bowl and rim top to show the condition of both. The rim top is smooth and has some beautiful birdseye grain. You can see the debris in the bowl and darkening on the inner edge. I also took photos of the acrylic stem showing the tooth marks and chatter on both sides ahead of the button.  I took a photo of the stamping on the underside of the shank. It is clear and readable as noted above. I took a photo of the bowl with the stem removed to give a sense of the proportion and appearance of the pipe without the stem.

I took a photo of the stamping on the underside of the shank. It is clear and readable as noted above. I took a photo of the bowl with the stem removed to give a sense of the proportion and appearance of the pipe without the stem. I took some photos of the crack and flaws in the bowl. The photos show the one in the heel and on the front of the bowl.

I took some photos of the crack and flaws in the bowl. The photos show the one in the heel and on the front of the bowl.

Now it was time to start working on the pipe itself. The bowl was slightly conical so I reamed it with a Savinelli Fitsall Pipe knife taking it back to bare briar. I sanded the bowl walls with 220 grit sandpaper wrapped around a piece of dowel. The bowl was significantly cleaner.

Now it was time to start working on the pipe itself. The bowl was slightly conical so I reamed it with a Savinelli Fitsall Pipe knife taking it back to bare briar. I sanded the bowl walls with 220 grit sandpaper wrapped around a piece of dowel. The bowl was significantly cleaner. I used a brass bristle wire brush to knock of the debris on the briar of the sandblast. Once I did that I decided to address the crack and fills in the heel of the bowl. I used my lens and light to magnify the crack and drill a small microdrill hole at each end of it with my Dremel.

I used a brass bristle wire brush to knock of the debris on the briar of the sandblast. Once I did that I decided to address the crack and fills in the heel of the bowl. I used my lens and light to magnify the crack and drill a small microdrill hole at each end of it with my Dremel. I filled in the drill holes in the briar and the track of the crack with clear CA glue. I used a dental spatula to press briar dust into the superglue over the crack and the drill holes. At the same time, I repaired the flaw on the front of the bowl. I went over the repaired areas with a brass bristle wire brush to knock off the excess glue and briar dust.

I filled in the drill holes in the briar and the track of the crack with clear CA glue. I used a dental spatula to press briar dust into the superglue over the crack and the drill holes. At the same time, I repaired the flaw on the front of the bowl. I went over the repaired areas with a brass bristle wire brush to knock off the excess glue and briar dust.

I scrubbed the exterior of the bowl with a tooth brush and undiluted Murphy’s Oil Soap. I scrubbed the smooth rim top and the sandblast walls with the toothbrush. I rinsed it off with warm running water and dried it with a soft towel. It looked much better and the rim top looked clean. The grain under the sandblast stood out clearly.

I scrubbed the exterior of the bowl with a tooth brush and undiluted Murphy’s Oil Soap. I scrubbed the smooth rim top and the sandblast walls with the toothbrush. I rinsed it off with warm running water and dried it with a soft towel. It looked much better and the rim top looked clean. The grain under the sandblast stood out clearly.

I cleaned out the internals of the shank and the airway in the stem with alcohol, cotton swabs and pipe cleaners to remove the buildup tars and oils. It smelled significantly better.

I cleaned out the internals of the shank and the airway in the stem with alcohol, cotton swabs and pipe cleaners to remove the buildup tars and oils. It smelled significantly better. I sanded the smooth rim top and edge with 320-3500 grit sanding pads. I was able to remove the darkening and really begin to see the grain.

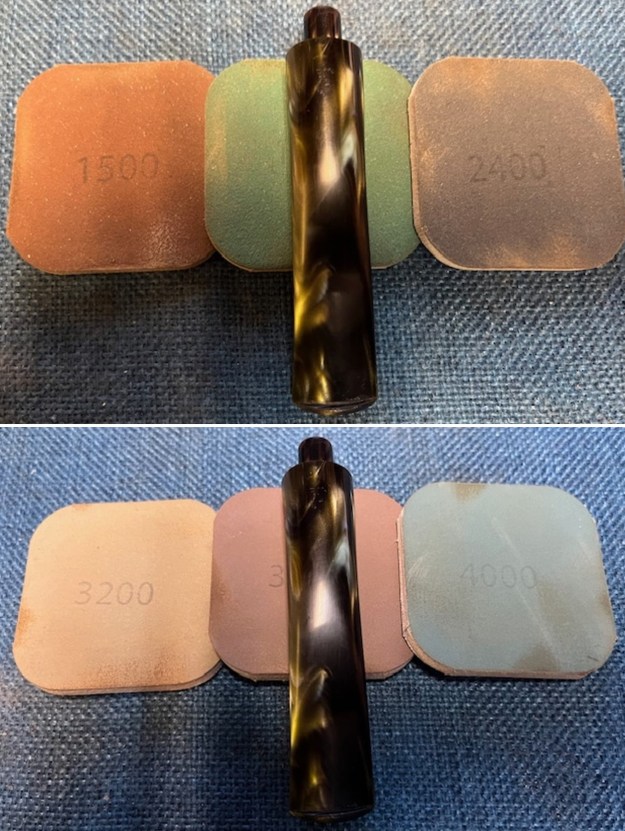

I sanded the smooth rim top and edge with 320-3500 grit sanding pads. I was able to remove the darkening and really begin to see the grain. I polished the rim top with 1500-12000 grit micromesh sanding pads – dry sanding with each pad and wiping it down with a damp cloth between pads. It took on a rich shine.

I polished the rim top with 1500-12000 grit micromesh sanding pads – dry sanding with each pad and wiping it down with a damp cloth between pads. It took on a rich shine.

I rubbed the bowl down with Before & After Restoration Balm. I worked it into the surface of the briar with my fingertips and a shoe brush to get it in the grooves. It works to clean, restore and preserve the briar. I let it do its magic for 15 minutes then buffed it off with a cotton cloth. The pipe looks incredibly good at this point in the process.

I rubbed the bowl down with Before & After Restoration Balm. I worked it into the surface of the briar with my fingertips and a shoe brush to get it in the grooves. It works to clean, restore and preserve the briar. I let it do its magic for 15 minutes then buffed it off with a cotton cloth. The pipe looks incredibly good at this point in the process.

I set the bowl aside and turned my attention to the stem. I filled in the deep marks in the acrylic stem with black rubberized CA glue. Once it hardened I flattened the repairs out with a small file. I sanded the stem with 220 grit sandpaper to blend them into the rest of the acrylic stem and started the polishing them with 600 wet dry sandpaper.

I set the bowl aside and turned my attention to the stem. I filled in the deep marks in the acrylic stem with black rubberized CA glue. Once it hardened I flattened the repairs out with a small file. I sanded the stem with 220 grit sandpaper to blend them into the rest of the acrylic stem and started the polishing them with 600 wet dry sandpaper.

I sanded the stem with 320-3500 grit sanding pads. I wiped the stem down after each sanding pad to remove the sanding debris and dust. The stem looked very good.

I sanded the stem with 320-3500 grit sanding pads. I wiped the stem down after each sanding pad to remove the sanding debris and dust. The stem looked very good. I set the bowl aside and turned my attention to the stem. I polished the stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with a damp cloth after each sanding pad. I finished polishing it with Before & After Pipe Stem Polish – both Fine and Extra Fine and buffed it off with a cotton cloth. I gave it a coat of Obsidian Oil to preserve and protect the stem.

I set the bowl aside and turned my attention to the stem. I polished the stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with a damp cloth after each sanding pad. I finished polishing it with Before & After Pipe Stem Polish – both Fine and Extra Fine and buffed it off with a cotton cloth. I gave it a coat of Obsidian Oil to preserve and protect the stem.

This American Reg. No. C 486/*S 5 Sandblast Dublin is a great looking pipe now that it has been restored. The brown stains really highlight the grain and the polished finish is stunning. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished American Mark Tinsky Dublin fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 2 ¼ inches, Outside diameter of the bowl: 1 ¾ inches, Chamber diameter: 7/8 of an inch. The weight of the pipe is 52 grams / 1.83 ounces. I will be packing this up and sending it back to Baker this week. I am looking forward to hearing what he thinks of it. Thanks for reading this blog and my reflections on the pipe while I worked on it. As always, I encourage your questions and comments as you read the blog. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipe men and women who hold our pipes in trust until they pass on into the trust of those who follow us.

This American Reg. No. C 486/*S 5 Sandblast Dublin is a great looking pipe now that it has been restored. The brown stains really highlight the grain and the polished finish is stunning. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished American Mark Tinsky Dublin fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 2 ¼ inches, Outside diameter of the bowl: 1 ¾ inches, Chamber diameter: 7/8 of an inch. The weight of the pipe is 52 grams / 1.83 ounces. I will be packing this up and sending it back to Baker this week. I am looking forward to hearing what he thinks of it. Thanks for reading this blog and my reflections on the pipe while I worked on it. As always, I encourage your questions and comments as you read the blog. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipe men and women who hold our pipes in trust until they pass on into the trust of those who follow us.