by Steve Laug

My brother Jeff picked up another Jobey Dansk Freehand pipe on December 17, 2020 from a seller in Cramerton, North Carolina, USA. It had really unique shape and some nice grain with spot carvings around the bowl and shank. There was some plateau on the top of the rim and on the end of the shank. There was a rustication on the right side of the bowl toward the heel of the bowl. I have worked on enough of these to know that were Danish Freehand pipes were carved by Karl Erik. This one was stamped on the underside of the shank end and read Jobey in script [over] Dansk [over] Handmade in Denmark. There was a faint 2 stamped below the Handmade stamp. The finish on this pipe was very dirty with dust and thick lava filing in the plateau top. The bowl had a very thick cake. There were oils and grime ground into the finish of the bowl and the grime was quite thick on the shank and sides. I am pretty sure that the vulcanite stem was a replacement. The fit to the shank was not good and there were tooth marks both sides of the stem at the button. There was a large bite through on the underside of the stem ahead of the button. Jeff took of the pipe to show the overall condition of the bowl and stem.

He took close up photos of the bowl and rim top from different angles to show the condition of the partial plateau finish. You can see the thick cake in the bowl and the heavy lava build up on the plateau rim top that almost fills in the valleys. It is hard to know if there is damage or if the lava protected it. The bowl has a thick cake that lining the walls and overflowing into lava. The next photos show the condition of the vulcanite stem which is oxidized and calcified. You can see the tooth marks and damage both on the surface of both sides ahead of the button.

He took close up photos of the bowl and rim top from different angles to show the condition of the partial plateau finish. You can see the thick cake in the bowl and the heavy lava build up on the plateau rim top that almost fills in the valleys. It is hard to know if there is damage or if the lava protected it. The bowl has a thick cake that lining the walls and overflowing into lava. The next photos show the condition of the vulcanite stem which is oxidized and calcified. You can see the tooth marks and damage both on the surface of both sides ahead of the button.

He took photos of the sides and heel of the bowl to show the lay of the grain and the heavy oils and build up around the pipe. It is a nice piece of briar with a unique and a patch of rustication on the bottom right side of the bowl toward the heel.

He took photos of the sides and heel of the bowl to show the lay of the grain and the heavy oils and build up around the pipe. It is a nice piece of briar with a unique and a patch of rustication on the bottom right side of the bowl toward the heel.

Jeff took a photo of the stamping on the underside of the shank to capture it. It was clear and read Jobey Dansk at the top. Under that it read Handmade in Denmark. Underneath that it is stamped with a number 2. The stamping on the 2 is very faint.

Jeff took a photo of the stamping on the underside of the shank to capture it. It was clear and read Jobey Dansk at the top. Under that it read Handmade in Denmark. Underneath that it is stamped with a number 2. The stamping on the 2 is very faint.  I wanted to look at who had carved the Jobey Dansk line to confirm some suspicions I had about it. I had a feeling that the pipes were carved by a Danish carver known as Karl Erik. I looked up the Jobey listing on Pipedia (https://pipedia.org/wiki/Jobey) and found the following information. I quote a portion of the article that is pertinent as follows.

I wanted to look at who had carved the Jobey Dansk line to confirm some suspicions I had about it. I had a feeling that the pipes were carved by a Danish carver known as Karl Erik. I looked up the Jobey listing on Pipedia (https://pipedia.org/wiki/Jobey) and found the following information. I quote a portion of the article that is pertinent as follows.

English – American – Danish – French… Information about the brand Jobey are only to be found in form of smithereens…

Probably established in England around 1920(?) the brand hiked into the USA later. In the course of time owner, distributor and manufacturer changed repeatedly. As far as known:

George Yale Pipes & Tobacco, New York (1942)

Norwalk Pipe Co., New York (1949)

Arlington Briar Pipes Corp., Brooklyn (when?)

Hollco International, New York (1969).

Weber Pipe Co., Jersey City, NJ (1970’s)

The Tinder Box, (1970’s – 80’s).

Throughout decades Jobey pipes were mainly sold in the USA, Canada and England but remained almost unknown in continental Europe. The bulk of Jobeys was predominantly made according to classical patterns and mainly in the lower to middle price range. The predominant judgment of the pipe smokers reads: “A well-made pipe for the price.” So there is hardly anything very special or exciting about Jobey pipes although a flyer from ca. 1970 assures: “The briar root Jobey insists upon for its peer of pipes is left untouched to grow, harden and sweeten for 100 years. […]Jobey uses only the heart of this century old briar and only one out of 500 bowls turned measures up to the rigid Jobey specifications.” 99.80% of cull… that makes the layman marveling!

Yet then there are partially really exciting Freehands mainly in the seventies, that Jobey – Weber owned back then – bought from Danish pipe genius Karl Erik Ottendahl. These pipes were offered as Jobey Dansk – ’70’s pure! (BTW waning sales caused Ottendahl to discontinue exports to the United States in 1987.)

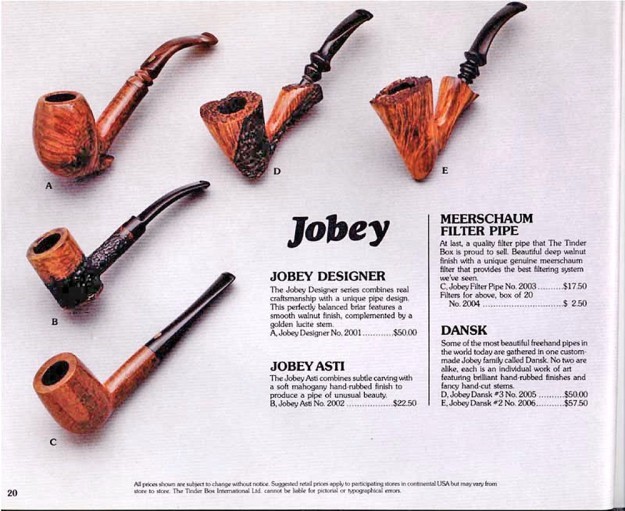

There was also an interesting Tinderbox catalogue page, provided courtesy of Doug Valitchka, that includes a note about the Jobey Dansk (https://pipedia.org/images/7/7a/Jobey1979.jpg). From that information I confirmed that the pipe that I was working on was carved by Karl Erik Ottendahl. There were some similarities to the Karl Erik pipes that I have worked on in the past. The dating of the pipe line in the 70s fits well with the pipe I have in hand.

From that information I confirmed that the pipe that I was working on was carved by Karl Erik Ottendahl. There were some similarities to the Karl Erik pipes that I have worked on in the past. The dating of the pipe line in the 70s fits well with the pipe I have in hand.

Now it was time to work on the pipe on my end. When I received it, Jeff had once again done an amazing job cleaning the pipe. He reamed it with a PipNet pipe reamer and got rid of the cake. He cleaned up the reaming with a Savinelli Fitsall Pipe Knife so that we could see the walls of the bowl and assess for damage. It was in good condition. He cleaned the internals of the shank and stem with cotton swabs, pipe cleaners, shank brushes and alcohol. He scrubbed the exterior with undiluted Murphy’s Oil Soap and a tooth brush. He rinsed the pipe under warm water. He dried it off with a cloth and then let it air dry. The stem was scrubbed with Soft Scrub and soaked in Briarville’s Stem Deoxidizer. It came out looking clean but the hole in the stem called for a replacement once again. The finish on the bowl and the rim top cleaned up nicely. I took pictures of the pipe to show how it looked when I brought it to the worktable.

I took some photos of the rim top and stem to show the condition of them both when the pipe arrived. Overall it looked good. There is some darkening and debris on the top of the bowl. The stem had some deep tooth marks ahead of the button on the topside and a large bite through on the underside ahead of the button.

I took some photos of the rim top and stem to show the condition of them both when the pipe arrived. Overall it looked good. There is some darkening and debris on the top of the bowl. The stem had some deep tooth marks ahead of the button on the topside and a large bite through on the underside ahead of the button.  I took a photo of the stamping on the underside of the shank. It is readable and in great condition. I removed the stem from the shank and took a photo of the pipe to show the look of the pipe.

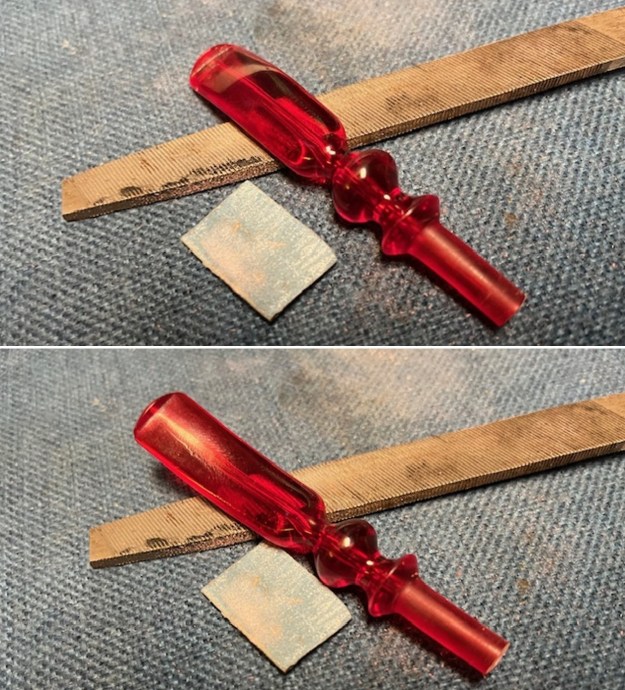

I took a photo of the stamping on the underside of the shank. It is readable and in great condition. I removed the stem from the shank and took a photo of the pipe to show the look of the pipe. I decided to start my work on the pipe by finding a new stem for the pipe. I went through my stems and found a nice acrylic saddle stem in a ruby colour. The tenon was quite long and would need to be shortened to match the drilling in the shank. I would need to shorten it by about a ¼ inch. I would also need to reduce the diameter of the tenon to get a proper fit in the shank but I think once the bowl was finished the stem would really look good. I took some photos of the bowl and the replacement stem.

I decided to start my work on the pipe by finding a new stem for the pipe. I went through my stems and found a nice acrylic saddle stem in a ruby colour. The tenon was quite long and would need to be shortened to match the drilling in the shank. I would need to shorten it by about a ¼ inch. I would also need to reduce the diameter of the tenon to get a proper fit in the shank but I think once the bowl was finished the stem would really look good. I took some photos of the bowl and the replacement stem. I took some photos of the bowl with stem to give a sense of what the combination would look like. The colour looks quite amazing with the straight grain around the bowl and shank.

I took some photos of the bowl with stem to give a sense of what the combination would look like. The colour looks quite amazing with the straight grain around the bowl and shank.

I started on fitting the stem to the shank. I used my Dremel and sanding drum to start the process of reducing the diameter and finished the work with a file and sandpaper.

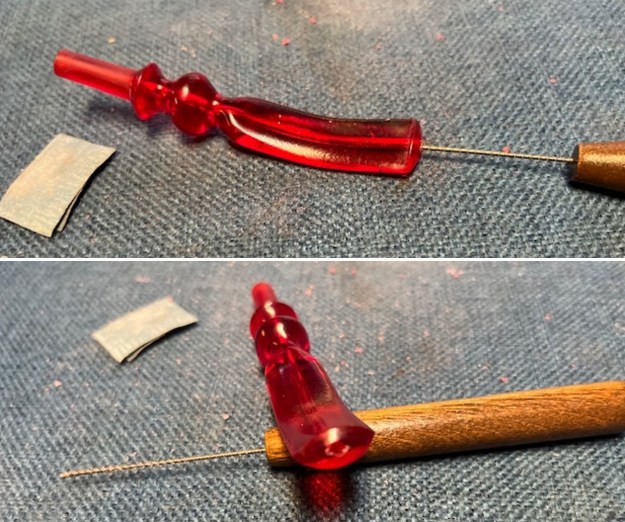

I started on fitting the stem to the shank. I used my Dremel and sanding drum to start the process of reducing the diameter and finished the work with a file and sandpaper.  I used a sharp pen knife chamfer the airway in the tenon end. The slight funnel really helps focus the smoke up the stem to the mouth.

I used a sharp pen knife chamfer the airway in the tenon end. The slight funnel really helps focus the smoke up the stem to the mouth. I used a small pottery saw to open up the single hole in button and begin to shape it in the form of a football. I further shaped it with a round and an oval file. I smoothed it out with a folded piece of sandpaper.

I used a small pottery saw to open up the single hole in button and begin to shape it in the form of a football. I further shaped it with a round and an oval file. I smoothed it out with a folded piece of sandpaper.

I sanded the stem with 320-3500 grit sanding pads. I wiped the stem down with an Obsidian Oil cloth after each sanding pad. Once I was finished it looked much better.

I sanded the stem with 320-3500 grit sanding pads. I wiped the stem down with an Obsidian Oil cloth after each sanding pad. Once I was finished it looked much better. I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with some Obsidian Oil. I finished polishing it with Before & After Pipe Stem Polish – both Fine and Extra Fine and buffed it off with a cotton cloth.

I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with some Obsidian Oil. I finished polishing it with Before & After Pipe Stem Polish – both Fine and Extra Fine and buffed it off with a cotton cloth.

I set the stem aside and worked on the bowl. I worked over the plateau finish with a brass bristle wire brush to knock of the debris in the valley and low spots of the finish. It looked better.

I set the stem aside and worked on the bowl. I worked over the plateau finish with a brass bristle wire brush to knock of the debris in the valley and low spots of the finish. It looked better. I moved from cleaning up the plateau to dealing with the darkening and damage to the inner edge of the rim. I used a folded piece of 220 grit sandpaper to work and smooth it out. It looked better when I had finished.

I moved from cleaning up the plateau to dealing with the darkening and damage to the inner edge of the rim. I used a folded piece of 220 grit sandpaper to work and smooth it out. It looked better when I had finished.  I sanded the bowl with 320-3500 grit sanding pads. I wiped the briar down with a damp cloth after each sanding pad to remove the debris. It started to look very good.

I sanded the bowl with 320-3500 grit sanding pads. I wiped the briar down with a damp cloth after each sanding pad to remove the debris. It started to look very good.

I polished the bowl with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the briar down after each pad with a damp cloth. The bowl is starting to look very good.

I polished the bowl with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the briar down after each pad with a damp cloth. The bowl is starting to look very good.

I worked some Before & After Restoration Balm into the surface of the briar with my fingertips and into the plateau rim top and shank end with a horsehair shoe brush to clean, enliven and protect it. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

I worked some Before & After Restoration Balm into the surface of the briar with my fingertips and into the plateau rim top and shank end with a horsehair shoe brush to clean, enliven and protect it. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

This is a beautiful Jobey Dansk Handmade Freehand by Karl Erik with a fancy, turned, ruby acrylic stem. It has a great look and feel. The shape fits well in the hand with the curve of the bowl and shank junction a perfect fit for the thumb around the bowl when held. I polished stem and the bowl with Blue Diamond polish on the buffing wheel. I gave the plateau on the rim top and shank end multiple coats of Conservator’s Wax. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The rich combination of browns and black in the smooth finishes and the plateau areas took on life with the buffing. The rich colour of the briar works well with the polished ruby acrylic stem. I like the grain and finished look of this Jobey Dansk pipe. Have a look at it with the photos below. The shape, finish and flow of the pipe and stem are very well done. The dimensions are Length: 6 ½ inches, Height: 2 ¼ inches, Outside diameter of the bowl: 1 ¾ wide, Chamber diameter: 1 inch. The weight of the pipe is 57 grams/1.98 ounces. This Danish Freehand is a real beauty. Thanks for walking through the restoration with me as I worked over another beautiful pipe. This one will be going on the rebornpipes store in the Danish Pipe Making Section shortly if you would like to add it to your collection. Thanks for your time.

This is a beautiful Jobey Dansk Handmade Freehand by Karl Erik with a fancy, turned, ruby acrylic stem. It has a great look and feel. The shape fits well in the hand with the curve of the bowl and shank junction a perfect fit for the thumb around the bowl when held. I polished stem and the bowl with Blue Diamond polish on the buffing wheel. I gave the plateau on the rim top and shank end multiple coats of Conservator’s Wax. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The rich combination of browns and black in the smooth finishes and the plateau areas took on life with the buffing. The rich colour of the briar works well with the polished ruby acrylic stem. I like the grain and finished look of this Jobey Dansk pipe. Have a look at it with the photos below. The shape, finish and flow of the pipe and stem are very well done. The dimensions are Length: 6 ½ inches, Height: 2 ¼ inches, Outside diameter of the bowl: 1 ¾ wide, Chamber diameter: 1 inch. The weight of the pipe is 57 grams/1.98 ounces. This Danish Freehand is a real beauty. Thanks for walking through the restoration with me as I worked over another beautiful pipe. This one will be going on the rebornpipes store in the Danish Pipe Making Section shortly if you would like to add it to your collection. Thanks for your time.