By Steve Laug

The next pipe on the worktable is a Danish made pipe from the workshop of Viggo Nielsen. It is a great looking long shank ¼ Bent Rhodesian. The pipe came to us from eBay on 01/22/2024 from a seller in Jordan, Minnesota, USA. It has great grain around the bowl and shank with some small fills on the bowl and the shank that are a bit swollen. The pipe is stamped on the left side and clearly reads BARI [over] Ruby and on the right side it reads Made in Denmark [over] 8042. The finish was dirty with dust and grime ground into the briar but great grain still shone through. The pipe is very dirty with a thick cake in the bowl and lava on the rim top. The rim top is thin and looks like the bowl might be slightly out of round but it was hard to know what was under the lava coat on the top and edges. There was a coat of varnish on the bowl that was spotty and uneven. The vulcanite taper stem was oxidized and dirty and had some light tooth chatter and marks on both sides ahead of the button. Jeff took these photos of the pipe before he started his cleanup work.

He took photos of the rim and bowl to show the condition of the bowl and rim top. You can see the thick cake in the bowl and a thick coat of lava on the rim top. He also took photos of the stem surfaces to show its overall condition when it arrived. It was oxidized and dirty and had light tooth marks and chatter on both sides.

He took photos of the rim and bowl to show the condition of the bowl and rim top. You can see the thick cake in the bowl and a thick coat of lava on the rim top. He also took photos of the stem surfaces to show its overall condition when it arrived. It was oxidized and dirty and had light tooth marks and chatter on both sides.

The photos of the sides and heel of the bowl show the grain showing through the finish around the bowl and shank sides. The rich reddish stain adds depth to the finish.

The photos of the sides and heel of the bowl show the grain showing through the finish around the bowl and shank sides. The rich reddish stain adds depth to the finish.

He took photos of the stamping on the sides of the shank. It was clear and readable as noted above. He also took a photo of the BARI stamp on the left side of the stem.

He took photos of the stamping on the sides of the shank. It was clear and readable as noted above. He also took a photo of the BARI stamp on the left side of the stem.

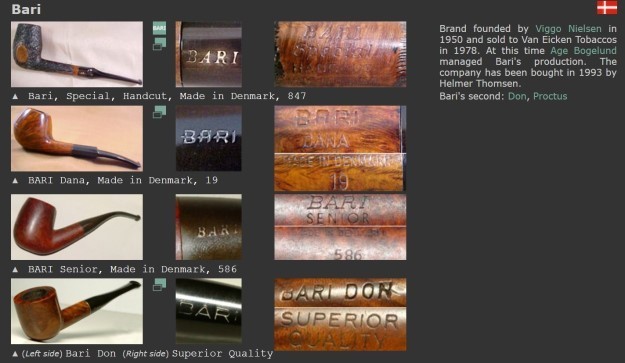

Before I started working on it I did a bit of research on the brand to remind myself of the maker. I have worked on quite a few Bari’s in the past so rather than rework all of that I am including the information I found while working on a Bari Special Handcut Made in Denmark Dublin Freehand (https://rebornpipes.com/2020/07/22/cleaning-up-a-danish-made-bari-special-handcut-b-dublin-freehand/). I quote below from that blog.

Before I started working on it I did a bit of research on the brand to remind myself of the maker. I have worked on quite a few Bari’s in the past so rather than rework all of that I am including the information I found while working on a Bari Special Handcut Made in Denmark Dublin Freehand (https://rebornpipes.com/2020/07/22/cleaning-up-a-danish-made-bari-special-handcut-b-dublin-freehand/). I quote below from that blog.

I quoted a section from Pipedia on Bari pipes (https://pipedia.org/wiki/Bari). It is good to be reminded of the fact that Viggo Nielsen was the pipe maker.

Pipedia states that Bari Piber was founded by Viggo Nielsen in Kolding, Denmark around the turn of 1950/51. His sons Kai and Jørgen both grew into their father’s business from a very young age and worked there till 1975. Both have become successful pipe makers.

Bari successfully adapted the new Danish design that had been started mainly by Stanwell for its own models. Bari was sold in 1978 to Van Eicken Tobaccos in Hamburg, Germany though the pipes were still made in Denmark. From 1978 to 1993 Åge Bogelund and Helmer Thomsen headed Bari’s pipe production.

Helmer Thomson bought the company in 1993 re-naming it to “Bari Piber Helmer Thomsen”. The workshop moved to more convenient buildings in Vejen. Bogelund, who created very respectable freehands of his own during the time at Bari got lost somehow after 1993. Bari’s basic conception fundamentally stayed the same for decades: series pipes pre-worked by machines and carefully finished by hand – thus no spectacular highgrades but solid, reliable every day’s companions were what they turned out. The most famous series are the smooth “Classic Diamond” and the blasted “Wiking”.

I did a quick look at Pipephil’s site (http://www.pipephil.eu/logos/en/logo-b1.html) and did a screen capture of the section on Bari pipes. Now that I was reminded about the Viggo Nielsen connection it was time to work on the pipe on my end. Jeff had done a great clean up of the pipe. He had reamed it with a PipNet reamer and took the cake back to bare briar. He cleaned up the remnants with a Savinelli Fitsall Pipe Knife. He scrubbed internals of the shank and stem with alcohol, cotton swabs, pipe cleaners and a shank brush. He cleaned the exterior of the pipe with undiluted Murphy’s Oil Soap and a tooth brush to remove the grime and the lava on the rim top. There were several fills on the bowl and the shank that were swollen and needed to sanded smooth. He scrubbed the stem with Soft Scrub to remove the debris that had accumulated on it. The stem was soaked in Briarville’s Pipe Stem Deoxidizer and then rinsed clean. The pipe looked clean and ready for the next step in the process. Here are some photos of it when I brought it to the table.

Now that I was reminded about the Viggo Nielsen connection it was time to work on the pipe on my end. Jeff had done a great clean up of the pipe. He had reamed it with a PipNet reamer and took the cake back to bare briar. He cleaned up the remnants with a Savinelli Fitsall Pipe Knife. He scrubbed internals of the shank and stem with alcohol, cotton swabs, pipe cleaners and a shank brush. He cleaned the exterior of the pipe with undiluted Murphy’s Oil Soap and a tooth brush to remove the grime and the lava on the rim top. There were several fills on the bowl and the shank that were swollen and needed to sanded smooth. He scrubbed the stem with Soft Scrub to remove the debris that had accumulated on it. The stem was soaked in Briarville’s Pipe Stem Deoxidizer and then rinsed clean. The pipe looked clean and ready for the next step in the process. Here are some photos of it when I brought it to the table.

I took photos of the rim top and the top and underside of the stem. You can see the clean bowl and rim top. The rim top showed some light damage on the top and the inner edge of the bowl. The inner edge was slightly out of round with nicks in the briar. The stem has light tooth chatter and marks on both sides ahead of the button. It is a nice looking pipe.

I took photos of the rim top and the top and underside of the stem. You can see the clean bowl and rim top. The rim top showed some light damage on the top and the inner edge of the bowl. The inner edge was slightly out of round with nicks in the briar. The stem has light tooth chatter and marks on both sides ahead of the button. It is a nice looking pipe. The next photos show the stamping on the left and right sides of the shank. It is clear and readable as noted above. The Bari stamp on the left side of the stem is visible in the first photo below. I also took the stem off the shank and took a photo of the pipe to show its parts.

The next photos show the stamping on the left and right sides of the shank. It is clear and readable as noted above. The Bari stamp on the left side of the stem is visible in the first photo below. I also took the stem off the shank and took a photo of the pipe to show its parts.

I started my work on the pipe by addressing the damage on the rim top and the inner edge with a folded piece of 220 grit sandpaper. It looked much better once finished.

I started my work on the pipe by addressing the damage on the rim top and the inner edge with a folded piece of 220 grit sandpaper. It looked much better once finished. To remove the damaged and spotty varnish coat I wiped the bowl down with alcohol on cotton pads. I was able to remove the spotty coat and the briar looked much better. The fills showed clearly on the shank the bowl.

To remove the damaged and spotty varnish coat I wiped the bowl down with alcohol on cotton pads. I was able to remove the spotty coat and the briar looked much better. The fills showed clearly on the shank the bowl.

I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I worked over the damaged fills at the same time. I wiped the bowl down with a damp cloth after each sanding pad. It really began to take on a shine.

I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I worked over the damaged fills at the same time. I wiped the bowl down with a damp cloth after each sanding pad. It really began to take on a shine.

I rubbed the bowl down with some Before & After Restoration Balm. I worked it into the briar with my fingertips. The product works to clean, renew and protect briar. I let it do its work for 15 minutes then buffed it off with a soft cloth. The pipe is really quite a beauty.

I rubbed the bowl down with some Before & After Restoration Balm. I worked it into the briar with my fingertips. The product works to clean, renew and protect briar. I let it do its work for 15 minutes then buffed it off with a soft cloth. The pipe is really quite a beauty.

I set the bowl aside and I polished the stem on both sides using micromesh sanding pads. I dry sanded the stem with the 1500-12000 grit pads, then wiped it down with a cloth impregnated with Obsidian Oil. I finished polishing it with Before & After stem polish – both Fine and Extra Fine. I gave it a final coat of Obsidian Oil and set it aside to dry.

I set the bowl aside and I polished the stem on both sides using micromesh sanding pads. I dry sanded the stem with the 1500-12000 grit pads, then wiped it down with a cloth impregnated with Obsidian Oil. I finished polishing it with Before & After stem polish – both Fine and Extra Fine. I gave it a final coat of Obsidian Oil and set it aside to dry.

This is another pipe I am excited to finish. It is a beautiful Bari Ruby Made in Denmark Bent Rhodesian. I put the pipe back together and buffed it lightly with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine and hand buffed it with microfiber cloth to deepen the shine. It is fun to see what the polished bowl looks like with the polished stem with the golden acrylic spacer. It really was a beautiful pipe. The sandblasted grain shining through the rich browns/black stain on this Bari Ruby Bent Rhodesian is nice looking and the pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 5 ¾ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 2 inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.66 ounces/47 grams. It is a beautiful pipe and one that will be on the rebornpipes store in the Danish Pipe Makers Section soon. If you are interested in adding it to your collection let me know. Thanks for walking through the cleanup with me as I worked over this pipe. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipemen and women who hold our pipes in trust until they pass on into the trust of those who follow us.

This is another pipe I am excited to finish. It is a beautiful Bari Ruby Made in Denmark Bent Rhodesian. I put the pipe back together and buffed it lightly with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine and hand buffed it with microfiber cloth to deepen the shine. It is fun to see what the polished bowl looks like with the polished stem with the golden acrylic spacer. It really was a beautiful pipe. The sandblasted grain shining through the rich browns/black stain on this Bari Ruby Bent Rhodesian is nice looking and the pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 5 ¾ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 2 inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.66 ounces/47 grams. It is a beautiful pipe and one that will be on the rebornpipes store in the Danish Pipe Makers Section soon. If you are interested in adding it to your collection let me know. Thanks for walking through the cleanup with me as I worked over this pipe. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipemen and women who hold our pipes in trust until they pass on into the trust of those who follow us.