Blog by Paresh Deshpande

Recently I had purchased a few pipes on eBay and this time the delivery was effected without any issues from the Seller. All the Sellers had described the pipes just as they are received, items were well packed and shipping was record quick making this a nice experience (far cry from all my previous experiences on eBay!). I shared the pictures of the pipe haul with members of my Pipe Club and this pair of cased Meerschaum called out to one of the founding members of the club and more importantly a dear friend of mine.

Looking at the pipe set, it is apparent that these pipes had seen many a summers, many a number of repair jobs more so to the stem including splicing and many ages of (mis?)use. The case consists of two Meerschaum pipes; a Dublin and a Billiard (or maybe a Tulip or even an Apple shape!!!). There are no visible stampings or markings either on the pipe or on the hard leather case except a small note with c.1920’s written on it (well, again veracity of this note cannot be established and needs to be considered with a pinch of salt, or rather a handful of salt!). This makes it impossible to firmly establish the provenance of this pipe set. However, the overall feel, appearance and quality make me want to believe that small little note. Here are a couple of pictures of the cased set of meer as it sits on my table.

Though both the pipes were worked on simultaneously, for the sake of brevity and convenience of explaining the process and how issues that cropped up on one pipe affected the other, I shall divide the write up in to two parts.

Though both the pipes were worked on simultaneously, for the sake of brevity and convenience of explaining the process and how issues that cropped up on one pipe affected the other, I shall divide the write up in to two parts.

Part 1: Dublin

The Dublin shaped meerschaum pipe is in pretty good condition with a thin layer of cake in the chamber. The rim top surface is clean and in good condition with no dents or dings over the rim edges. The major issue on this pipe is with the stem. Somewhere down the line during its previous innings, the Amber stem on this pipe must’ve broken in half and was repaired using a multicolored acrylic or cheap plastic stem spliced in to place at the tenon end. The seating of the tenon in to the shank end is very loose and barely holds the walls of the mortise. This seems to be the main reason why this pipe was so sparingly used as evidenced by the thin layer of cake in the chamber. The following pictures will give a general idea of the condition of this pipe as it sits on my workbench.

Detailed Inspection

Detailed Inspection

The chamber is clean with a thin layer of even cake. The rim top surface is clean and in pristine condition without any dents and dings over the rim top. The inner and outer rim edges are smooth, even and without any darkening along the edges. The rim appears thinned out in 12 o’clock direction along the outer rim edge. I think it is the design feature which has the stummel in a slight inwards turn near the upper surface. However, the chamber itself is perfectly rounded.

The stummel surface shows a few scratches, but none serious enough to draw away your attention from the beauty of the bowl. The inward turning shape to the upper surface of the stummel that I have mentioned above is indicated by green arrows. There are a couple of dark spots over the stummel surface and encircled in pastel blue. The shank end shows residual white tape and is indicative of an earlier repair work to the shank end. The band, though identical to the other pipe in this set, appears to be fixed after the pipe was completed. The white Teflon tape, in all probability, was used to tighten the seating of the threaded tenon in to the mortise. However, this was an utter failure as the tenon is too loose in the mortise and is the reason for this pipe being so sparingly used.

The stummel surface shows a few scratches, but none serious enough to draw away your attention from the beauty of the bowl. The inward turning shape to the upper surface of the stummel that I have mentioned above is indicated by green arrows. There are a couple of dark spots over the stummel surface and encircled in pastel blue. The shank end shows residual white tape and is indicative of an earlier repair work to the shank end. The band, though identical to the other pipe in this set, appears to be fixed after the pipe was completed. The white Teflon tape, in all probability, was used to tighten the seating of the threaded tenon in to the mortise. However, this was an utter failure as the tenon is too loose in the mortise and is the reason for this pipe being so sparingly used.

The stem is where maximum repair work is required. The stem has been spliced and repaired previously with the rounded slot end made of Amber while the tenon end is a similar colored variegated acrylic or plastic stem. The joint is easily discernible and is encircled in Red. Though the stem airway is aligned, the stem shape is not. The mismatched stem shape is indicated by green. The tenon is too short and filthy and very loose fitting in the shank. The slot end has tooth indentations and chipped surface. Given the present condition of the stem and its seating in to the mortise, I shall be replacing the stem itself to make it both functional and aesthetically appealing to the eye (that’s what the intention is!).

The stem is where maximum repair work is required. The stem has been spliced and repaired previously with the rounded slot end made of Amber while the tenon end is a similar colored variegated acrylic or plastic stem. The joint is easily discernible and is encircled in Red. Though the stem airway is aligned, the stem shape is not. The mismatched stem shape is indicated by green. The tenon is too short and filthy and very loose fitting in the shank. The slot end has tooth indentations and chipped surface. Given the present condition of the stem and its seating in to the mortise, I shall be replacing the stem itself to make it both functional and aesthetically appealing to the eye (that’s what the intention is!).

The Process

The Process

I started this project by reaming the chamber with my smaller fabricated knife and scraped out all the carbon from chamber. I used a 220 grit sand paper, pinched between my thumb and forefinger, to sand the inner walls of the chamber of the pipe. Once I had reached the bare walls, I wiped the chamber with a cotton pad dipped in isopropyl alcohol. This removed all the residual carbon dust and also rid the chamber of all ghost smells.

I followed it up by cleaning of the mortise and air way of the pipe using hard bristled and regular pipe cleaners, q-tips dipped in alcohol. The mortise and the draught hole were given a final clean with shank brushes dipped in alcohol. I dried the mortise with a rolled paper napkin. The shank internals and the draught hole are now nice and clean with an open and full draw.

I followed it up by cleaning of the mortise and air way of the pipe using hard bristled and regular pipe cleaners, q-tips dipped in alcohol. The mortise and the draught hole were given a final clean with shank brushes dipped in alcohol. I dried the mortise with a rolled paper napkin. The shank internals and the draught hole are now nice and clean with an open and full draw. I cleaned the external surface of the Meerschaum bowl with Murphy’s Oil soap and cotton swabs. I wiped the bowl surface with a moist cloth to remove the soap and grime that remained on the surface. The stummel surface cleaned up nicely. The scratches and dents and dings over the stummel surface are now clearly visible and will be addressed to an extent when the stummel is polished using the micromesh pads.

I cleaned the external surface of the Meerschaum bowl with Murphy’s Oil soap and cotton swabs. I wiped the bowl surface with a moist cloth to remove the soap and grime that remained on the surface. The stummel surface cleaned up nicely. The scratches and dents and dings over the stummel surface are now clearly visible and will be addressed to an extent when the stummel is polished using the micromesh pads.

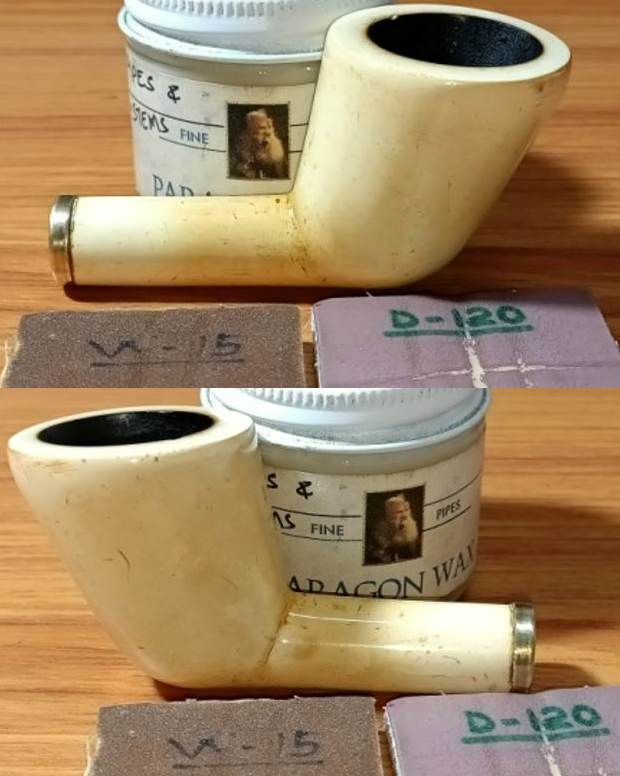

I polished the rim top surface and rim edges with micromesh pads. I then went on to dry sand the entire stummel with 1500-12000 grit pads and wiped the bowl down with a damp cloth to remove the dust that was left behind by the sanding. I had planned to minimize the scratches but not necessarily remove them. These lacerations and dings must have had a history and I wanted to preserve it. Once I was done with the micromesh cycle, I applied a small quantity of Paragon wax and vigorously polished it off with a microfiber cloth. The stummel now has a nice deep shine to it.

I polished the rim top surface and rim edges with micromesh pads. I then went on to dry sand the entire stummel with 1500-12000 grit pads and wiped the bowl down with a damp cloth to remove the dust that was left behind by the sanding. I had planned to minimize the scratches but not necessarily remove them. These lacerations and dings must have had a history and I wanted to preserve it. Once I was done with the micromesh cycle, I applied a small quantity of Paragon wax and vigorously polished it off with a microfiber cloth. The stummel now has a nice deep shine to it.

Next I decided to address the stem repairs or rather stem replacement since the damage to the already repaired stem was far too extensive and yet it would not make this pipe fully functional since the tenon was too loose and too short. The stem that I selected is a beautiful yellow acrylic stem that perfectly matched the shank face diameter. I selected a Delrin tenon that perfectly threaded in to the mortise for a snug fit.

Next I decided to address the stem repairs or rather stem replacement since the damage to the already repaired stem was far too extensive and yet it would not make this pipe fully functional since the tenon was too loose and too short. The stem that I selected is a beautiful yellow acrylic stem that perfectly matched the shank face diameter. I selected a Delrin tenon that perfectly threaded in to the mortise for a snug fit. Now it was necessary to down size the smooth end of the tenon to fit in to the stem face. I mounted a 150 grit sanding drum on to my hand held rotary tool and sand down the smooth end of the tenon till I had achieved a rough seating of the tenon in to the stem face. My previous experience has taught me an invaluable lesson; “SAND ONCE AND CHECK TWICE”!! Once I had achieved a rough seating, I got down to the arduous and time consuming task of manually sanding down the smooth portion of the tenon with a folded piece of 220 grit sandpaper till I had achieved a perfect seating of the tenon in to the stem. Here I was extra careful and vigilant while sanding the sides of the tenon and frequently checked the alignment of the tenon airway with the stem airway and finally through the shank airway and right through the draught hole.

Now it was necessary to down size the smooth end of the tenon to fit in to the stem face. I mounted a 150 grit sanding drum on to my hand held rotary tool and sand down the smooth end of the tenon till I had achieved a rough seating of the tenon in to the stem face. My previous experience has taught me an invaluable lesson; “SAND ONCE AND CHECK TWICE”!! Once I had achieved a rough seating, I got down to the arduous and time consuming task of manually sanding down the smooth portion of the tenon with a folded piece of 220 grit sandpaper till I had achieved a perfect seating of the tenon in to the stem. Here I was extra careful and vigilant while sanding the sides of the tenon and frequently checked the alignment of the tenon airway with the stem airway and finally through the shank airway and right through the draught hole.  Once I was sure that the tenon, stem and shank face and airways are all aligned and seated flush, I glued the tenon in to the stem. I took some time to admire the overall appearance of the pipe and I like it very much.

Once I was sure that the tenon, stem and shank face and airways are all aligned and seated flush, I glued the tenon in to the stem. I took some time to admire the overall appearance of the pipe and I like it very much. Next on the agenda was to match the length of the replacement stem with that of original stem. Using needle file and 150 grit sand paper, I sand the slot end of the replacement stem till I achieved a perfect length match. Even though it took me a few man hours and lots of efforts, I was able to achieve the desired length. I checked the seating of the pipe in to the case and noted with satisfaction that the case closed without any gaps. However, in achieving the desired length, the button edges on the new stem were sanded down. This necessitated rebuilding of button edges on the new stem.

Next on the agenda was to match the length of the replacement stem with that of original stem. Using needle file and 150 grit sand paper, I sand the slot end of the replacement stem till I achieved a perfect length match. Even though it took me a few man hours and lots of efforts, I was able to achieve the desired length. I checked the seating of the pipe in to the case and noted with satisfaction that the case closed without any gaps. However, in achieving the desired length, the button edges on the new stem were sanded down. This necessitated rebuilding of button edges on the new stem. With clear CA superglue, I rebuild the buttons using layering technique. Once the glue had hardened, using a needle file, I roughly shaped the buttons and further fine tuned the buttons using a piece of 330 grit sandpaper.

With clear CA superglue, I rebuild the buttons using layering technique. Once the glue had hardened, using a needle file, I roughly shaped the buttons and further fine tuned the buttons using a piece of 330 grit sandpaper.

The slot end at this stage is rounded and the horizontal slot needs to be carved. I marked the center line on either sides of the orifice and using a slot file, I carved out a horizontal slot. The stem looks good at this stage.

The slot end at this stage is rounded and the horizontal slot needs to be carved. I marked the center line on either sides of the orifice and using a slot file, I carved out a horizontal slot. The stem looks good at this stage. Next the stem was subjected to a full cycle of polishing using micromesh pads.

Next the stem was subjected to a full cycle of polishing using micromesh pads. With the shaping and polishing of the replacement stem completed, I turned my attention back towards the stummel. I gave a beeswax polish to the meerschaum bowl. I assembled the equipment and materials that would be needed during the process viz heat gun, paper towels, q-tips and a Katori, a steel container graciously lent by Abha from her kitchen and of course, beeswax. I stuffed the chamber with cork to prevent inadvertent seepage of the melted beeswax into it. Next, I melted a sufficient quantity of beeswax in the katori using my heat gun and thereafter heated the stummel. Using a folded pipe cleaner, I completely coated the stummel with the wax and continued the application till the surface was saturated with the beeswax and set the stummel aside to absorb the wax. I reheated the stummel with the heat gun about 20 minutes later and let the excess wax either be absorbed or drip off from the stummel surface. I rubbed off the excess wax with a soft cotton cloth and brought a deep shine to the surface with a microfiber cloth.

With the shaping and polishing of the replacement stem completed, I turned my attention back towards the stummel. I gave a beeswax polish to the meerschaum bowl. I assembled the equipment and materials that would be needed during the process viz heat gun, paper towels, q-tips and a Katori, a steel container graciously lent by Abha from her kitchen and of course, beeswax. I stuffed the chamber with cork to prevent inadvertent seepage of the melted beeswax into it. Next, I melted a sufficient quantity of beeswax in the katori using my heat gun and thereafter heated the stummel. Using a folded pipe cleaner, I completely coated the stummel with the wax and continued the application till the surface was saturated with the beeswax and set the stummel aside to absorb the wax. I reheated the stummel with the heat gun about 20 minutes later and let the excess wax either be absorbed or drip off from the stummel surface. I rubbed off the excess wax with a soft cotton cloth and brought a deep shine to the surface with a microfiber cloth.

With the replacement stem all shaped and aligned and the bowl waxed and polished, I had completed the refurbishing of this pipe from the cased pair and set the pipe aside.

With the replacement stem all shaped and aligned and the bowl waxed and polished, I had completed the refurbishing of this pipe from the cased pair and set the pipe aside.

However, little did I know at this stage that all the man hours and efforts that I had put in making this replacement stem to make this pipe aesthetically beautiful and functionally sublime would come to a naught due to certain challenges that I was presented with while working on the second pipe from the set. I shall cover those aspects in Part- II of the write up. It will suffice to say here that I had to discard this stem and fabricate a new vulcanite stem from scratch.

PART-I (B)

Now that I have decided to match the stem on this pipe to the vulcanite stem that I had fabricated on the second pipe from the set, I first selected a vulcanite stem that would more or less be a perfect match to the butterscotch yellow acrylic stem that was made earlier. I would need to shape the flare at the slot end to a nice smooth taper (indicated by yellow lines), reshape the slot end to an orifice with old style rounded buttons and would need to greatly reduce the diameter of the tenon (indicated by red arrows) for a snug fit in to the mortise. Once that was achieved, I would need to clean and polish the vulcanite to a nice black shine. Here is a picture to give you an idea of both the stems. First I removed the metal stinger from the tenon end by heating it with the flame of a match light and pulling it out with a pair of nose pliers. I followed this with cleaning the stem internals using anti-oil dish washing soap on a thin shank brush and rinsing it under warm running water. I ran a couple of pipe cleaners through the airway to completely remove any residual traces of soap and also to dry it out.

First I removed the metal stinger from the tenon end by heating it with the flame of a match light and pulling it out with a pair of nose pliers. I followed this with cleaning the stem internals using anti-oil dish washing soap on a thin shank brush and rinsing it under warm running water. I ran a couple of pipe cleaners through the airway to completely remove any residual traces of soap and also to dry it out.

With a 150 grit sanding drum mounted on my hand held rotary tool, I sized down the tenon to achieve a rough match with the mortise size. I fine tuned the seating of the tenon in to the mortise by sanding it further with a 180 grit sand paper till I had achieved a snug fit.

With a 150 grit sanding drum mounted on my hand held rotary tool, I sized down the tenon to achieve a rough match with the mortise size. I fine tuned the seating of the tenon in to the mortise by sanding it further with a 180 grit sand paper till I had achieved a snug fit. As I was trying out the seating of the tenon in to the mortise a second time, the brass ring separated from the shank end with threaded portion of the mortise while revealing a minor crack at the shank end (unfortunately, in my haste to address the newly presented challenge, I missed out on taking pictures of the damaged shank end). The problems are continually mounting unabated!!

As I was trying out the seating of the tenon in to the mortise a second time, the brass ring separated from the shank end with threaded portion of the mortise while revealing a minor crack at the shank end (unfortunately, in my haste to address the newly presented challenge, I missed out on taking pictures of the damaged shank end). The problems are continually mounting unabated!!

Luckily, I had a Sterling silver band that I previously got made from a local silversmith which perfectly fit the shank end. I filled the crack with thin CA superglue. Once the glue had seeped in to the crack and hardened completely, I attached the band over the shank end with CA superglue and set it aside for the repairs to cure. Now I turned my attention back to the stem. The tenon mod was completed and next I decided to address the extra flare at the slot end of the replacement stem. I wanted an old style stem with an orifice to match the correct time period of 1920s and had achieved it to a certain extent on the billiards pipe from the set. I cut about half an inch off the slot end. This achieved two aims; firstly, the flare was reduced and secondly, I now had an orifice at the slot end. I further evened out the cut surface by sanding the surface over a 220 grit sand paper.

Now I turned my attention back to the stem. The tenon mod was completed and next I decided to address the extra flare at the slot end of the replacement stem. I wanted an old style stem with an orifice to match the correct time period of 1920s and had achieved it to a certain extent on the billiards pipe from the set. I cut about half an inch off the slot end. This achieved two aims; firstly, the flare was reduced and secondly, I now had an orifice at the slot end. I further evened out the cut surface by sanding the surface over a 220 grit sand paper. Thereafter began the arduous task of eyeballing and filing with flat/ semi-circular needle files. It did a take long time and lots of elbow grease to achieve a rough desired shape. I further fine tuned the rough edges and shape by sanding the stem surface using a 220 grit sand paper.

Thereafter began the arduous task of eyeballing and filing with flat/ semi-circular needle files. It did a take long time and lots of elbow grease to achieve a rough desired shape. I further fine tuned the rough edges and shape by sanding the stem surface using a 220 grit sand paper.

Next, I wet sand the entire stem with 600, 800, 1000, 1500 and 2000 grit sand papers. This progressive use of higher grit sandpapers helps to, firstly, reduce the sanding marks left behind by the more abrasive ones, secondly, completely eliminate the oxidation while imparting a clean shine to the stem surface. Thirdly, this also helped to even out the sanding marks left behind by the flat needle files. I applied a little EVO and set the stem aside for a few minutes.

Next, I wet sand the entire stem with 600, 800, 1000, 1500 and 2000 grit sand papers. This progressive use of higher grit sandpapers helps to, firstly, reduce the sanding marks left behind by the more abrasive ones, secondly, completely eliminate the oxidation while imparting a clean shine to the stem surface. Thirdly, this also helped to even out the sanding marks left behind by the flat needle files. I applied a little EVO and set the stem aside for a few minutes. I went through the 1500 to 12000 grit micromesh pads to wet sand the stem. The stem now has a nice deep shine along the entire stem surface. I rubbed a small quantity of EVO and set the stem aside for the oil to hydrate the stem surface.

I went through the 1500 to 12000 grit micromesh pads to wet sand the stem. The stem now has a nice deep shine along the entire stem surface. I rubbed a small quantity of EVO and set the stem aside for the oil to hydrate the stem surface. To finish the restoration of this pipe, I polished the stem with Blue Diamond compound and subsequently with carnauba wax using my hand held rotary tool. I once again vigorously buffed the stummel with microfiber cloth to bring a deep shine. The finished pipe actually looks much attractive in person than in the pictures below.

To finish the restoration of this pipe, I polished the stem with Blue Diamond compound and subsequently with carnauba wax using my hand held rotary tool. I once again vigorously buffed the stummel with microfiber cloth to bring a deep shine. The finished pipe actually looks much attractive in person than in the pictures below.