This post may be controversial to some folks as it is about the reworking of a pipe from a living artisan. I know that many would never do such a thing and would either sell the pipe or leave it in the collection. I chose to do neither of those things. Knowing that when Stephen gave it to me it was not one that he was going to sell and that in some ways he saw as problematic made this adaptation an easy choice for me.

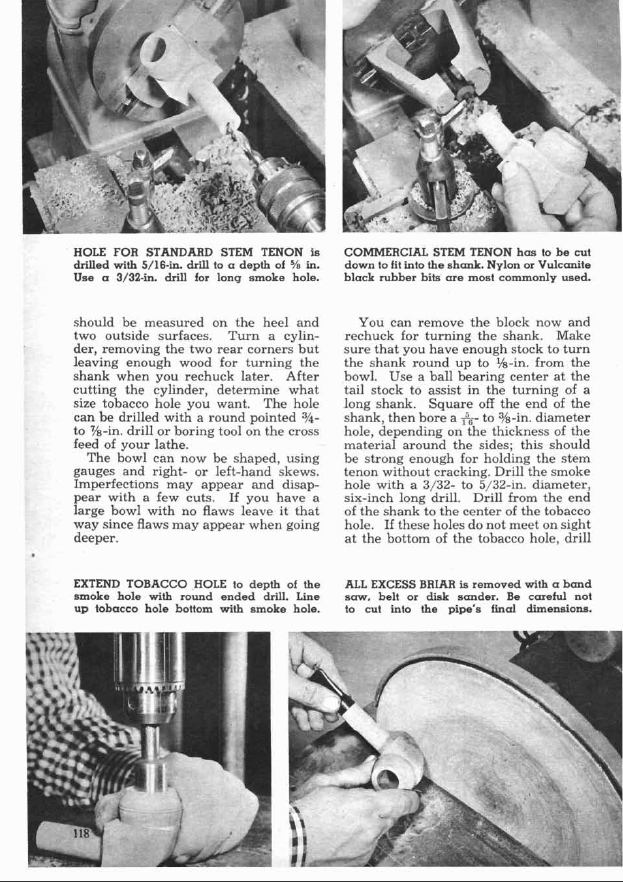

Quite a few years ago now – enough years have passed that I am not sure when – I used to visit Stephen Downie when he lived in Vancouver. We had connected through the Vancouver Pipe Club and I enjoyed his company. When I visited I would pick up tips on pipe making that I could use in my pipe refurbishing – stem making, sanding techniques, staining processes, etc. I enjoyed looking through his box of throw away stummels that for one reason or another had problems and did not make the grade. He would often give me one or two to use to practice carving. I enjoyed the process of working with these blocks just to learn about briar and how it responds when cut and sanded. I learned about sand pits and flaws in the block and got to play around with the tools to remove the flaws as much as possible and craft a passable pipe for me to smoke.

One day when I was going through the box he gave me this pipe that he had made in 2004. If memory serves me correctly, Stephen said that he thought that the drilling of the bowl had left it too thin in the bottom front. As such he would not place it on his site for sale. He figured that it would still smoke well if broken in carefully. I gladly took it home with me, smoked a few bowls and then put it in the pipe cupboard. Over the years I have rarely smoked it much as I found the hanging tail fin on the underside very uncomfortable to hold. I took it out of the cupboard when I was choosing a pipe to smoke. Sometimes I picked it up and smoked it but it never quite made it into the rotation. The pipe smokes very well so it was not a matter of mechanics that kept me from picking it up more often, but it just seemed that the fin was in the way.

Fast forward to a wedding I did just a few months ago (2013) for a couple of good friends of mine here in Vancouver. At the reception dinner I connected with Stephen and his wife. We talked about life in general, books we were reading and writing and pipes we were enjoying. We talked of the pipes Stephen was carving and the ones I was refurbishing. We laughed over different details of the work while we sipped our drinks and ate the buffet supper.During the course of our conversation Stephen talked about an idea he had about reworking pipes for people and giving them new looks and improved feel. If they had a pipe in their collection that just did not get smoked often for whatever reason he would reimagine and rework it for them. He called his idea a Phoenix pipe. As we talked about it I found that I liked the idea a lot. When I went home that evening I could not get it out of my mind. I looked over some of my old pipes that for one reason or another have not seen the use they deserve. I sorted through them to see if one of them might be a candidate for this idea of his. I picked up the old finned pipe that he had given me many years before. As I looked it over I had several ideas of how to rework it. I put it back in the cupboard and let it sit for several months while I thought about what do about it.

I picked it up again several days ago and looked it over. I like colour of the stain but wondered what it would look like if I darkened it. I like the feel of the bowl in the hand. I liked the curves of the rim and the bowl to the shank. I liked the flow of the curve to the stem. I liked the shape of the shank and the black acrylic insert and the olive wood extension on the shank. The mortise was Delrin lined and the drilling was vintage Downie – well drilled, straight and clean. The fit of the stem was stellar. The stem was also comfortable and the button thin as is my preference. The Cumberland colour and material suited the pipe well. There were many things I liked about it. I turned the ideas over in my mind of what I might do to rework it. I thought that I would remove the fin on the bottom of the shank and the nob on the bottom of the stem and I would have it done. I thought about calling Stephen and setting up a meeting to drop the pipe off for him to reimagine – do his Phoenix work on it and see what he could do with it. But after looking it over for a while I decided rather than sending it to him I would do a Phoenix rework on it myself.

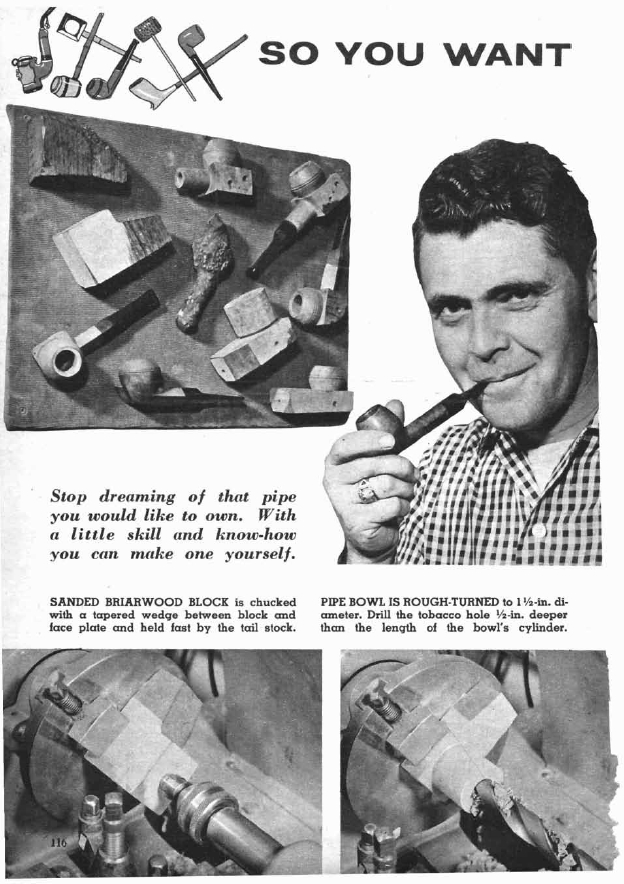

The first series of four photos are of the pipe Stephen named the Alopias (named after a Thresher Shark). This is what it looked like when I took it from the cupboard to work on it.

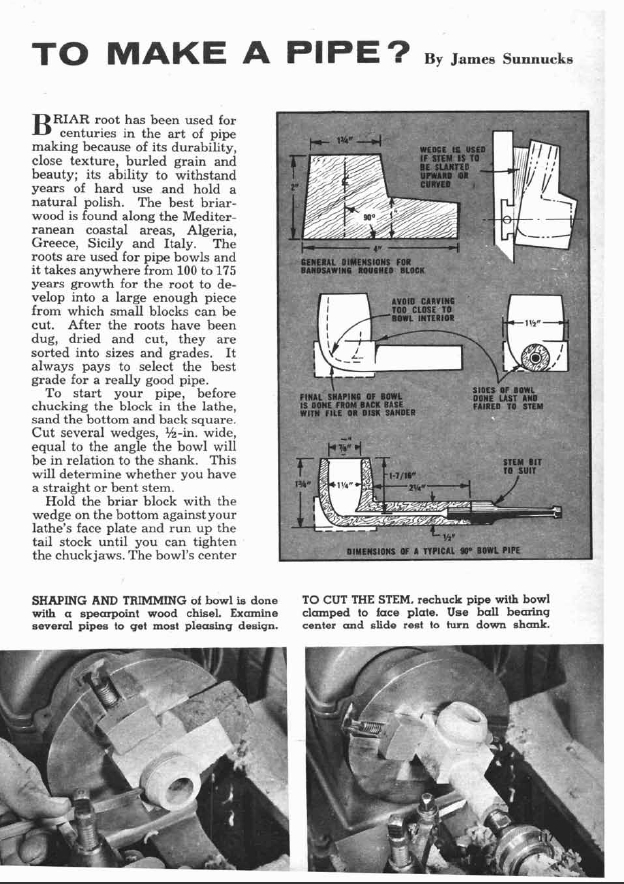

I used a Dremel with a sanding drum to take down the fin on the shank and the nob on the Cumberland stem. I figured that would be fairly straight forward work – not a big deal to do with the Dremel. And it certainly worked easily enough. Removing the two parts of the pipe was pretty quick work. I finished with the sanding drum and left a little extra on the shank and stem that I would sand away by hand. I wanted to make sure that I could match the flow and shape of the shank and stem. The next three photos show what the pipe looked like after I had removed the fin and nob. It certainly changed the appearance and the hand feel of the pipe. I began to think that my reimagining was going to work out well.

I took the pipe to my work table and sanded the stem and shank with medium grit emery paper and also with 220 grit sandpaper to further shape the flow of the shank and stem. I wanted to sand a gentle taper from the shank into the stem. I worked at the slope to get it the way I saw it in my head. Once I had that done I sanded it with a medium grit sanding sponge to smooth out the scratches and marks in the briar and the Cumberland. I really like the way the pipe was beginning to look. As I looked at the pipe I thought that a little more sanding of the slope would really make the pipe look proper.

But that is when the job became more than I had bargained for. In order to accomplish what I had in mind I would have to sand down the shank a bit more. To match the stem and shank flow it would need to have some more of the shank extension sanded away. That is when it hit! MAJOR PROBLEM! When I took the stem off the shank to check things before sanding I saw that there was not enough olive wood on the extension between the Delrin insert and the outside of the shank to take any more material off the shank. If I continued to sand it as I had been doing would expose the Delrin and ruin the shank. Even the amount of sanding and sloping that I had done had made the wood very thin on the underside of the shank. I could not do any more sanding on it without ruining it. So that is where this Phoenix took a turn and a new solution had to be worked out.

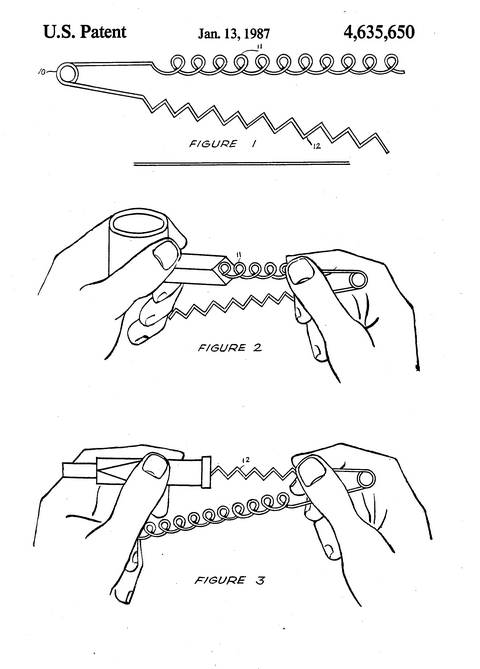

I looked at it and scribbled out some sketches of how to rework things. I thought about shortening the shank but really did not want to do that. So in the end I decided to remove the old stem altogether and shape a vulcanite stem for the pipe. The polished black of the vulcanite would match the band of black on the shank. It would also bookend the olive wood shank extension. So I found an oval saddle stem in my box of stems and turned the tenon with the PIMO tenon tool. Once I had a good fit on the tenon, I used the Dremel with the sanding drum to shape the stem to the shank. I decided to make the stem a half saddle by removing the saddle portion on the underside of the stem. This was tedious and slow work as I did not have any margin for damage on the shank itself. Once I had sanded the stem to a close fit with the Dremel I did the rest of the work by hand with files and sandpaper. The next four photos show the new vulcanite stem after all the fitting and shaping work had beencompleted. I still needed to polish and bend the stem to make the angle similar to the original.

At this point in the process I wiped down the bowl with an acetone soaked cotton pad to remove the wax and finish from the pipe so that I could restain and blend the sanded portion of the shank on the bottom with the stain on the bowl. I also chose to stain the olive wood with the same stain to add a patina like quality to the look. The next three photos show the pipe after it has been wiped down and is ready to be stained.

I did some more sanding on the shank and stem using a fine grit sanding sponge to smooth out any of the remaining surface scratches.I followed up by sanding the shank and the stem with micromesh sanding padsand then wiped it down a final time to remove the sanding dust and other debris before staining.The photo below shows the bowl and shank ready for staining.

I stained the bowl and shank with an oxblood stain to give a reddish over stain to the brown undercoat. I wiped it on, flamed it, wiped it on again, and flamed it again. The red overcoat gave a depth to the colour on the bowl that had not been present before. It also gave a patina to the olivewood that really highlighted the grain in the wood. After the stain had dried I took the pipe to the buffer and buffed the bowl and stem with Tripoli and with White Diamond. The next series of four photos show pipe after I had buffed it. The new look seemed to work with the pipe. From the photos I could see that I also needed to make some adjustments to the underside of the shank to give it a better flow.

In the above photos it is evident that there was still a slight hump on the bottom of the shank on both sides of the acrylic band. That hump bothered me so I took it back to the Dremel and sanding drum and removed some more of the material on the shank around the acrylic band. I wanted to smooth out the flow of the bottom of the shank from the tip of the stem to the bottom of the bowl. One of the issues that I had to think through in doing this was that some of the original Downie stamp would lost. I would not remove all of the stamping but some of the letters on the stem side of the shank would be lost. I decided that I had made enough changes to the pipe that to not finish would leave the job half done. Sanding it down definitely improved the way it looked. After I finished sanding with the DremelI sanded the entire underside of the shank with 220 grit sandpaper, a medium and fine grit sanding sponge and then micromesh sanding pads 1500-3200 grit. I stained the portion I had sanded with the oxblood stain to match the rest of the pipe and then buffed it with White Diamond. I gave the entirety several coats of carnauba wax and then buffed with a soft flannel buff to polish it. The final series of four photos show the finished pipe.