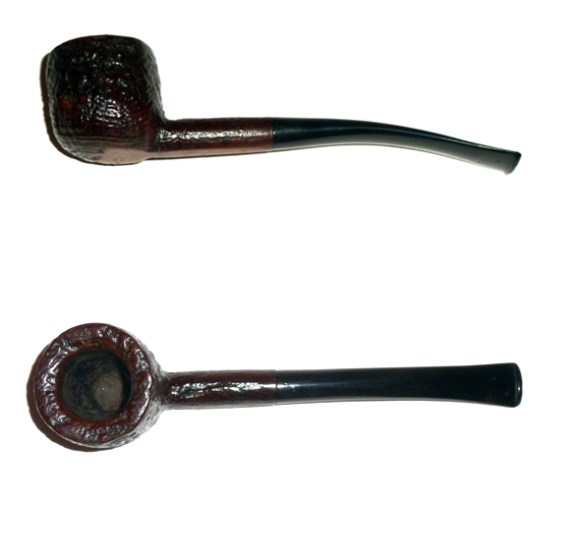

Here is the mate of the other Bewlay Olde 49 bent billiard that I posted about recently. They had both been sitting in my box of pipes to repair and refurbish for several years now. Yesterday I worked on the first one and restemmed it. This afternoon I decided to work on second one. The finish was exactly like the other one – grime ground into the surface and the wax and shine were gone. The top of the bowl was tarred and caked. The stem had been chewed through. The button was gone and the previous owner had made it into some kind of dental bit but cutting a groove in the stem along the end of the chewed off portion. It was a mess. I decided to cut off the chewed portion of the stem and then rework a button into the smooth surface of this one rather than restem it. I find that often this takes far more time to do this than it would just to cut a new stem for it. Such was the case with this one.

I used my Dremel with the sanding drum on it to cut back the damaged stem. I removed just under ½ inch of the stem. I cut it back until there was plenty of vulcanite over the airway on the top and bottom so that I could work in the new button and open the airway into a nice slot. The next series of pictures show the cut off stem. You can see that there is plenty of stem left for the work of shaping a new button.

The next four pictures show the stem from the end and then from the top and the bottom to give a good idea of what the stem looked like once I had removed the damaged material. I worked on the end of the stem to keep it a straight cut. I would eventually curve the ends of the new button but at this point I wanted to keep a straight edge to work with. You can see from the airway pictured in the first picture that there is plenty of vulcanite above and below the airway for the new button to be cut.

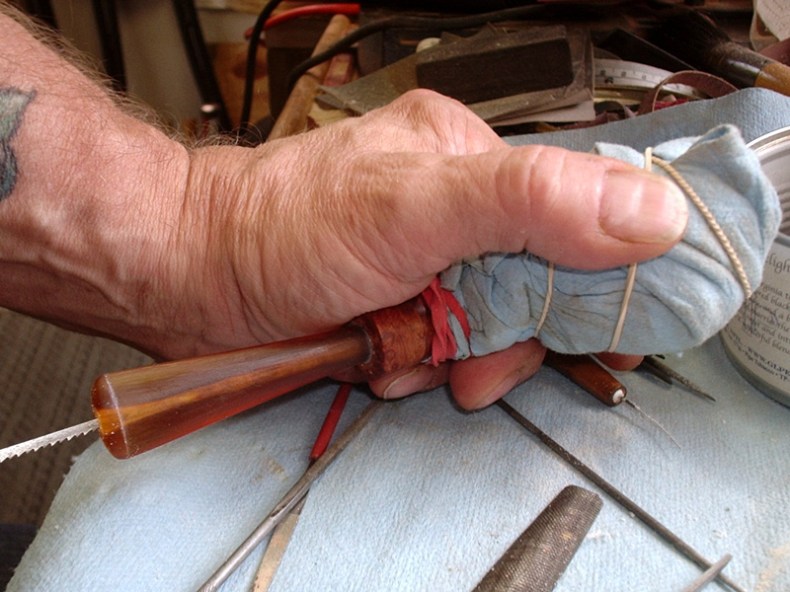

I used a rasp with a flat straight edge to do the initial cutting work on the button. I followed up with the flat needle file to clean up the work after the rasp did the initial work. The first two photos below show the freshly cut button. The first photo is of the underside of the stem. The button is cut to match an existing Bewlay stem that I have here. I also wanted it wide enough that I could taper it on the ends and the front edge after I had cut the slot. The second photo shows the topside of the stem after the initial cut of the new button. You can see from that photo that the left edge of the button has a slight indentation in it that will need to be worked on to make the button have a smooth and flowing shape.

The next series of four pictures show the stem after I have smoothed out the initial cut of the rasp with the needle file in the picture. The edge of the button is becoming distinct and clear. The first picture shows the underside of the stem and the clean flow of the button. The second picture shows the topside of the stem. Notice that the line is at a slight angle in the photo. That will be corrected once the left side of the button has been built up with some super glue. Pictures 3 and 4 show the shape of the button and how it is beginning to take the final shape – the oval or “football” shape that was on the old Bewlay pipes. At this point I had not begun to work on the airway to open it up and make a smooth slot into the stem.

I continued to work on the button and the surface of the stem to smooth out the transition and shape and to give some definition to the edge of the button. I used a variety of sandpapers and emery cloths to do the work. For emery cloth I used medium and fine grit and for sandpaper I used 240 and 280 grit. The next two photos show the look of the stem at this point. The line of the button on the top is now straightened out. The spot on the bottom edge of the button in the first photo is the cleaned up divot or dent in the button.

In the next two photos I wanted show the developing profile of the stem and button. The button is actually beginning to show quite clearly and is distinguishable from the surface of the stem.

Quite a bit more sanding needed to be done to clarify the edges and the cut of the button. In the next two photos you can see the new button very clearly. I also had used some clear super glue to build up the top of the button and fill in the divot. I sanded it smooth once it was dry. In the first picture below you can see that the divot is gone and a black spot is in its place. The second photo shows the ongoing development of the underside of the stem and button.

I then used my needle files to work on the slot and open up the airway from the button end. I used an oval needle file to begin to cut the ends of the slot open. The four pictures below show the development of the slot from the start to the finished shape that I was aiming for. It is a nice open draw and should deliver a good smoke. In the fourth picture you can also see that I have tapered the button back toward the slow so that it is a good smooth transition and is comfortable in the mouth. I used a folded strip of emery cloth and 240 grit sandpaper to sand the inside of the slot and smooth the internals.

At that point I decided to take a break from the stem and work on the bowl finish. I wiped down the bowl and rim with acetone to clean off the existing finish and give me a clear surface to work with. This one also has some interesting grain patterns under the old finish. It is a bit more mixed cross grain and birdseye with no real pattern to the grain like the other Olde 49. But it cleaned up nicely.

I sanded the stem some more with micromesh sanding pads – 1500-12,000 grit to get rid of the file marks and sandpaper marks that were left behind. I wet the stem and sanded them through the various grits. The photos below show the rich blackness of the stem that has come back with all the sanding.

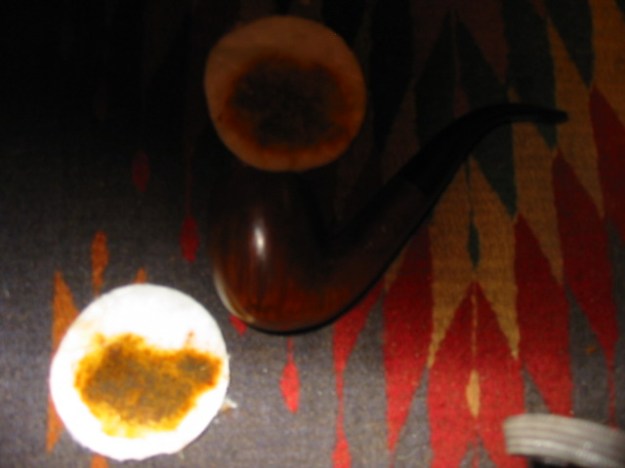

At this point I decided to restain the pipe. I did so with a Dark Brown aniline stain. I flamed it to set the stain and stained it a second time. I took pictures but the batteries on the camera gave out at this point and I was left with no photos of the stained pipe. It was dark like the other Bewlay pipe so I wiped it down with acetone on cotton pads to lighten the colour. The picture below gives a bit of a look at the pads and the dark stain that came off with the wash. The pipe is a little dark. This was the last of my batteries and the only picture that came out at this point in the process.

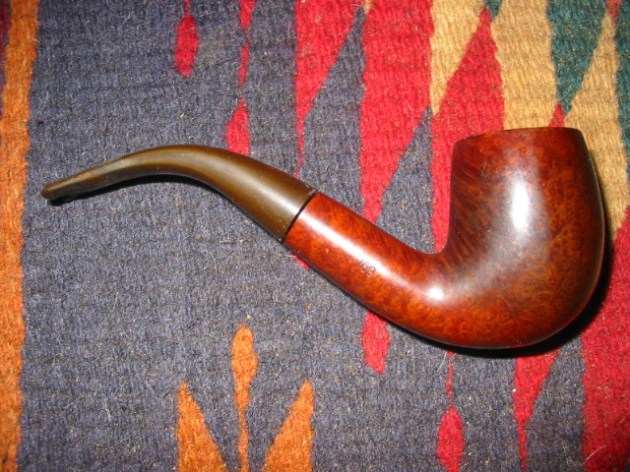

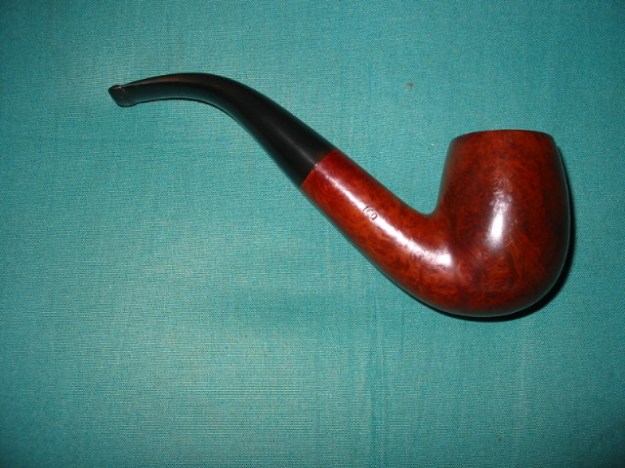

The next four pictures are of the finished pipe. The stain came out very nicely with the grain coming through very well. I buffed it with White Diamond once I had wiped it down with the acetone. The shine came up well on this one. I also buffed the stem with White Diamond and then gave the pipe several coats of carnauba wax and buffed it with a soft flannel buff.

The last picture is of the two Bewlay Olde 49 pipes together and ready to smoke. In person they are not quite as red as they come out in these photos. The rich older brown stain really matches these two well.