Blog by Gan Barber

It is a privilege to be able to post this blog entry from a friend and co-laborer in the refurbishing hobby. I have learned much from Gan, including the use of the alcohol bath for soaking bowls and preparing them. In fact as I read this report I am amazed at all the things we do similarly. I appreciate his taking the time to write this up to share here at rebornpipes. I look forward to more articles from Gan, as I am sure you will also after reading this one. Thanks Gan!

Well, the work is done, so it’s time to sit back, light up a bowl of Perreti 9575, and record this adventure….

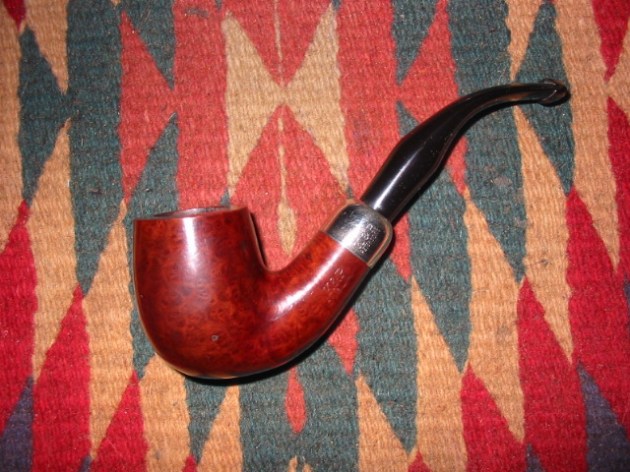

I am not an expert on dating Petersen Pipes, but from the little I know, this one appears to be a Pre-Republic era vintage. There are no markings on the briar or stem. The hallmark on the band indicates nickel, not silver, and provides no dating information. The K&P, Peterson, Dublin stamping is the only indication that the pipe dates from the Pre-Republic era.

It came to me in a sorry state of repair, and, after some preliminary cleaning, sat in my ‘Lazarus’ box for many years. The shank had been snapped from the bowl, the rim was dented, and the P-Lip modified. It was never going to be a collector piece. Still, it held some promise……

Before I begin the cleaning phase of any project, I like to remove any excess cake. I’m not looking to do anything more than scrape away thick accumulations from the bowl in order to find possible charring or burn-out. In this case, the break was clean, and exhibited no signs of burning that may have contributed to the damage. There was a small dent on the upper left rim of the bowl, leading me to believe that the previous owner liked to tap out the dottle, and had done so once too often.

Satisfied that the bowl was structurally sound, I placed it into a 91% Isopropyl alcohol bath. Once I removed the band, the broken shank followed.

I have had favorable results using this method to strip and clean a stummel. Using the highest percentage Isopropyl alcohol I can find (91%), means that only 9% of the solution is water. The low percentage of water allows the briar to dry rapidly once removed from the bath with very little residual moisture. I have soaked stummels for days without ill effects, though the extended time provides little in the way of additional cleaning. It can help with reducing strong ghosts, though. The alcohol will soften even the most stubborn cake, and sweeten the bowl as well as any other method.

Once the bowl had soaked long enough so loosen the dirt and soften the cake, I removed it from the bath and immediately reamed the bowl, removing as much cake as possible without quite getting down to bare briar. My tool of choice here is a Senior Adjustable Reamer. Not that it’s the only tool that will work; it just happens to be what I have and works quite well for this task.

With the reaming completed, the stummel went back into the bath for another wash. I prefer to do the preliminary cleaning wet, so the stummel will see the bath frequently. The advantages of working wet are two-fold: The alcohol lubricates the mechanical action of the steelwool, mitigating scratching, and the wetting reveals any missed areas requiring additional attention. I worked the wet stummel with 0000 steel wool until most of the dirt, grime and tar were gone.

While the bowl soaked in the alcohol bath, the vulcanite stem soaked in a solution of Oxy-Clean (1/4 scoop to 16 ounces of clean, warm water). Depending on the level of oxidation, I will let the stem soak anywhere from 30 minutes to overnight. Again, I’ve left stems soaking for days without detriment. Generally, I like to soak the stem for two to three hours. The oxidation will turn to a yellow-white slime, and the majority of it will come off quite easily with 0000 steel wool. There was no logo present, so I used the 0000 liberally to achieve a thorough cleaning. Another advantage of the Oxi-Clean soak is its ability to loosen any gunk that has accumulated in the smoke passage. Several bristle pipe cleaners are all that are needed to literally pull the residue from the passage. Another pass with a regular pipe cleaner and some alcohol will remove any traces of tar.

Below are the bowl, shank, and stem after soaking in their respective baths and an initial wet scrub with the 0000 steel wool. Later on in the refurb, I will continue to clean them, but by dipping the steel wool into the alcohol for the wood and the Oxi-clean for the stem, rather than re-immersing them.

Once I was satisfied with the initial cleaning, it was time to move on to the most challenging aspect of this project – mating the shank to the bowl.

There are a number of factors to consider when choosing the proper bonding agent to use in repairing a broken or cracked stummel. Heat, moisture, clamping time and compatibility with wood are paramount. Traditional outdoor rated aliphatic glues (Tite-Bond, Elmers, etc.) are resistant to moisture, but I don’t trust them to withstand moist heat. Polyurethane adhesives are stronger and more resistant to both heat and moisture, but have high expansion rates and excessive foaming. Both require extended clamping periods, which is extremely challenging due to the irregular shape of a stummel.

My adhesive of choice is a a fast set epoxy – JB Kwik. It is extremely strong (though not as strong as regular Weld Bond), heat resistant to 500+ degrees F, impervious to moisture, and has a clamping time of only 3 minutes. Mixed from two parts (epoxy/catalyst), it has a reasonable working time, and the two pieces of the pipe stummel can be held together with strong hand pressure for three minutes and then released.

To rejoin the shank to the bowl, I carefully aligned the two pieces so that I could easily find the correct registration before mixing a small amount of the epoxy. I applied it to both surfaces with a toothpick, then pressed the shank and bowl together, squeezing as much epoxy out of the joint as hand pressure would allow. I held them this way for three minutes. I did not worry about any squeeze-out getting into the air passage – yet.

After hand clamping for three minutes, I gently set the stummel down and let it rest for another 7 minutes. If properly mixed, Weld Bond Quick will be set to a rubbery stage after ten minutes (at 70 degrees F). At this point, I took a utility knife and carefully lifted the squeeze out off of the briar. It should peel like a rubber gasket if you catch it at the right time, leaving only a dark oily residue where it contacted the briar. Next, I took the drill bit from the Senior Reamer, and gently worked it through the airway. Care must be taken to use as little pressure as possible to twist and push out any epoxy the made its way into the passage. Although Weld Bond is non-toxic when cured, if cleaned out properly, little if any will be present in the airway.

I allowed the epoxy to cure for 6 hours, and then set to work gently sanding the joint with 400 grit emery to fare the seam as smooth as possible without altering the shape of the pipe. The only caveat to using this epoxy – it is rather viscous and will leave a faintly visible line at the joint no matter how well the parts are mated. I’ve found that after sanding, staining and buffing, this line will all but disappear.

The stummel after roughing in with the 400 grit emery. The graining did little to hide the seam on the left side…..

…while on the right, the grain pattern was more favorable and the seam blended in nicely.

With the shank and bowl rejoined and fared, I finished cleaning the briar with 0000 steel wool wetted with alcohol. Working wet with alcohol eases the scuffing of the steel wool and reveals the grain and any remaining flaws that may need attention. It also removes any oils or dirt introduced from handling the raw wood. The JB Kwik is impervious to the alcohol.

The next stage consisted of wet sanding with 600 grit. I used alcohol as a lubricant. When finished with the 600, I took the bowl to the buffer for a gentle once over with red rouge. This serves to deepen the color of the briar and reveal any scratches or imperfections that the finer grits will have difficulty removing. Satisfied with the results, I continued to wet sand with 1500 grit emery. The final sanding stages were done dry with 3600 and 6000 micro-mesh. At this point in the process, I was simply polishing the briar to prepare it for staining.

I chose Feibings Light Brown dye and gave the stummel a wash coat, undiluted, using a cotton Q-Tip. I set the stain with my Perdomo table-top lighter, and then gave it a thorough rub down with a microfiber cloth. The microfiber works to even out any imperfections in the finish, and noticeably polishes the dye to a nice luster. The bowl is now ready for the buffer.

The stem received an additional scrub with 0000 steel wool wetted with Oxi-Clean to remove any remaining oxidation. I then wet sanded, with water now, using 400 and then 600 grit emery. A quick and gentle buff with red rouge to find any remaining scratches from the steel wool and sandpaper was followed by a wet sand with 1500 emery. I then polished the vulcanite with 3600 and 6000 micro-mesh to prepare it for the buffer.

Both the stem and bowl were given a soft buffing with white diamond on the buffer and then wiped down with microfiber to remove any trace compound. I then swapped out the white diamond wheel for the wax one, and applied three coats of caranauba wax to the bowl. I like to use a moderate amount of pressure when applying wax as the caranauba is extremely hard and requires the heat generated to go on properly.

After the stem received a coat of Walker Briar Works sealer/wax and the nickel band was polished with Never Dull wadding, everything went back together and was ready to be enjoyed once again. It’s far from perfect, but then, it’s all about the journey, isn’t it?

Thanks to Steve for inviting me to contribute.

Best Regards,

Gan Barber