Blog by Steve Laug

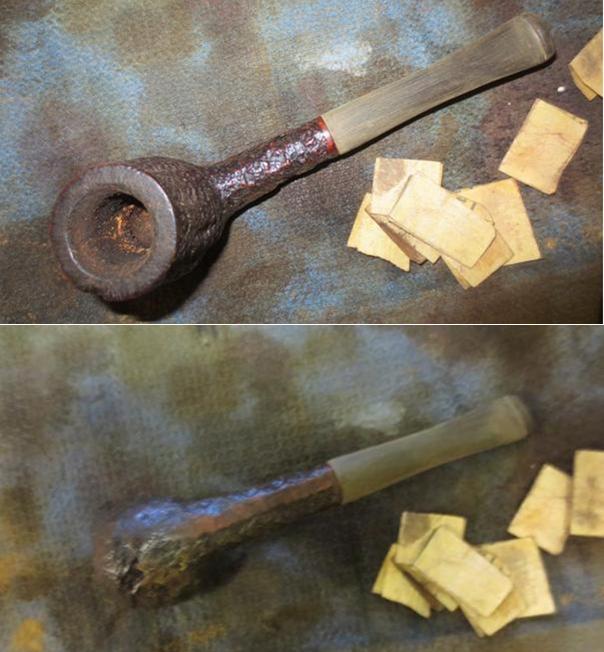

After I had settled into my hotel in Sofia, Bulgaria on a recent trip Dal took me to one of his pipe hunting haunts – an outside antique market in the shadow of Sofia’s largest church building – Nevski Cathedral. We visited the same vendor where he had purchased the Dr. Plumb Oom Paul pipe that he restored and restemmed. He had a lot of pipes on his table for sale. I worked through them and purchased one – a bent billiard with a windcap. Then I went through a bag of bowls and stems that he had and chose the bowl shown in the photo below. The bowl was stamped Shell Pipe 141. The combination sandblast and rustication give the pipe a great look. The finish looked to be pretty decent under the grime that filled the nooks and crannies of the blast. The rim was filled in with tars and oils to the point that the rustication on the surface was invisible. There was a pretty thick uneven cake throughout the bowl. The shank was dirty and almost clogged with tars. There was no stem on the pipe but there was no crack in the shank and I was pretty certain that I had a stem that would fit it once I got home to Vancouver.

I went through my can of stems and found a stem that would fit with a bit of adjustment. I sanded the tenon in order to get a proper fit in the mortise of the bowl. The stem was slightly larger in diameter than the shank end and would need to be reduced to fit. The star on the stem would disappear once the stem was properly fit in the shank.

I went through my can of stems and found a stem that would fit with a bit of adjustment. I sanded the tenon in order to get a proper fit in the mortise of the bowl. The stem was slightly larger in diameter than the shank end and would need to be reduced to fit. The star on the stem would disappear once the stem was properly fit in the shank.

I used the Dremel and sanding drum to reduce the diameter of the stem to match the shank. I sanded it with the stem in the pipe to make sure that I could match the stem and shank. I sanded it as close as possible with the Dremel and then worked on it by hand to get the lines of the fit correct.

I used the Dremel and sanding drum to reduce the diameter of the stem to match the shank. I sanded it with the stem in the pipe to make sure that I could match the stem and shank. I sanded it as close as possible with the Dremel and then worked on it by hand to get the lines of the fit correct. I sanded the stem with 220 grit sandpaper to remove the scratches left behind by the Dremel sanding drum and to fine tune the fit against the shank.

I sanded the stem with 220 grit sandpaper to remove the scratches left behind by the Dremel sanding drum and to fine tune the fit against the shank.

With the stem fit completed I turned to the bowl. I took a close-up photo of the bowl to show the build up on the rim and the state of the cake in the bowl.

With the stem fit completed I turned to the bowl. I took a close-up photo of the bowl to show the build up on the rim and the state of the cake in the bowl. I reamed the bowl back to bare briar with a PipNet pipe reamer and finished cleaning it up with a Savinelli Pipe Knife.

I reamed the bowl back to bare briar with a PipNet pipe reamer and finished cleaning it up with a Savinelli Pipe Knife.

I scrubbed the sandblast/rusticated finish with Murphy’s Oil Soap and a tooth brush and worked on the rim with a wire brush.

I scrubbed the sandblast/rusticated finish with Murphy’s Oil Soap and a tooth brush and worked on the rim with a wire brush. I rinsed the bowl with warm water under the tap (being careful to keep it out of the inside of the bowl). The cleaned briar is shown in the next series of photos.

I rinsed the bowl with warm water under the tap (being careful to keep it out of the inside of the bowl). The cleaned briar is shown in the next series of photos.

I cleaned out the airway in the stem, mortise and airway in the bowl with pipe cleaners, cotton swabs and alcohol.

I cleaned out the airway in the stem, mortise and airway in the bowl with pipe cleaners, cotton swabs and alcohol.

With the bowl cleanup finished and the internals on the stem down it was time to work on the finish of the stem. I wet sanded it with 1500-2400 micromesh sanding pads and gave it a coat of Obsidian Oil. I dry sanded it with 3200-4000 grit micromesh pads and gave it another coat of oil. I finished sanding it with 6000-12000 grit pads and gave it a final coat of Oil. I let it sit until the oil was dry.

With the bowl cleanup finished and the internals on the stem down it was time to work on the finish of the stem. I wet sanded it with 1500-2400 micromesh sanding pads and gave it a coat of Obsidian Oil. I dry sanded it with 3200-4000 grit micromesh pads and gave it another coat of oil. I finished sanding it with 6000-12000 grit pads and gave it a final coat of Oil. I let it sit until the oil was dry.

I buffed the bowl and stem with Blue Diamond on the wheel. I used a light touch on the bowl and a heavier touch on the stem as I did not want to get the polishing compound in the grooves and crevices of the blast. I gave the stem multiple coats of carnauba wax and buffed it with a clean buffing pad. I gave the bowl several coats of Conservator’s Wax and buffed it with a shoe brush. I hand buffed the finished pipe with a microfibre cloth. The finished pipe is shown below. I am pleased with the outcome. The bowl from Sofia, Bulgaria and the new stem from Canada work well together. Thanks for looking.

I buffed the bowl and stem with Blue Diamond on the wheel. I used a light touch on the bowl and a heavier touch on the stem as I did not want to get the polishing compound in the grooves and crevices of the blast. I gave the stem multiple coats of carnauba wax and buffed it with a clean buffing pad. I gave the bowl several coats of Conservator’s Wax and buffed it with a shoe brush. I hand buffed the finished pipe with a microfibre cloth. The finished pipe is shown below. I am pleased with the outcome. The bowl from Sofia, Bulgaria and the new stem from Canada work well together. Thanks for looking.