Blog by Steve Laug

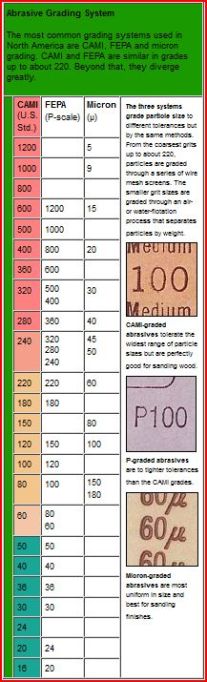

I thought it might be helpful to take some time to address the issue of sandpapers and sanding with regard to the work I do on stems both in removing oxidation and the removal of tooth chatter. I found a great chart on the grits of sandpapers that will help explain the designation system I refer to when I speak of various grits of sandpaper.

I thought it might be helpful to take some time to address the issue of sandpapers and sanding with regard to the work I do on stems both in removing oxidation and the removal of tooth chatter. I found a great chart on the grits of sandpapers that will help explain the designation system I refer to when I speak of various grits of sandpaper.

When I start on stem that are highly oxidized I use the CAMI (or US Standard system) 240 grit sandpaper. This is the crossover grit between the medium grit sandpapers and the fine grit sandpapers. 280 grit is the first fine grit sandpaper and 220 grit is the last medium grit sandpaper. The 240 grit works very well in removing the surface oxidation and also tooth chatter and tooth dents that have been raised to the surface. I always sand with this paper in vertical direction from the tenon to the button. I have learned that to sand the horizontal direction leaves scratches that are deeper and much harder to remove with the finer grits of sandpaper.

From that point on I have used 320 and 340 fine grit sandpaper but will often skip ahead to 400 grit wet dry sandpaper that works well with or without water. I personally use it with water – wetting the stem and then sanding the scratches left by the 240 grit sandpaper. I begin sanding in a vertical direction up and down the stem and finish sanding the stem in the horizontal direction around the stem from tenon to button. This sanding removes much of the scratching and prepares the stem for further sanding with finer grit papers.

I skip to the 600 grit wet dry sandpaper next to keep refining the sanding of the scratches. By this point the stem is a matte black and clean of most of oxidation. Again I use the paper wet. I wet the stem and sand both vertically and horizontally. I finish the sanding horizontally before moving on to the next grit. If it is available to me I use 1200 grit wet dry paper next to finish off the sandpapers. This grade of paper gives a nice smooth finish.

From this point on in the sanding process I use micromesh sanding pads or micromesh sand paper in the fine grits. I begin with the 1500 grit sanding pad pictured in the photo to the left. The makers of the micromesh pads use a colour system to identify the grit of the pad. The 1500 is the copper/reddish brown coloured pad at the top left of the photo. I use all of the pads with water. I wet the stem and then sand it with the pad. The 1500 grit pad works well to remove any remaining scrat ches and begins to polish the stem. The wet stem will need to be wiped off regularly of the slurry that is left from the wet sanding dust.

ches and begins to polish the stem. The wet stem will need to be wiped off regularly of the slurry that is left from the wet sanding dust.

The 1800 grit pad brings the smoothness of the stem one step closer to finished. I always use it wet as well. Once I have sanded the stem to this point I wipe it down and wet it with clean water to see if any scratches remain. If there are some I work on them with the 1800 grit or go back to the 1500 grit until I have removed them. These pads work exceptionally well around stem logos. The 2400 grit takes the shine deeper into the vulcanite or Lucite. I use this to polish the entire stem from tenon to the button. Again I use all pads with water – wetting the stem and sanding them horizontally at this point. The 3200 through the 4000 grit polishes the stem more deeply with each higher grit pad. Used wet and wiped off after sanding the finish of the stem should begin to take on more of a shine and the matte finish should begin to disappear.

The last three grits of micromesh – 6000 to 12000 at first seemed to be over kill to me. But each time I use them I find that the difference between each one is significant. The difference between the 8000 and the 12000 grit is the most dramatic. The 12000 grit used wet leaves the stem with a glassy finish that is ready to have a final buff with carnauba wax.