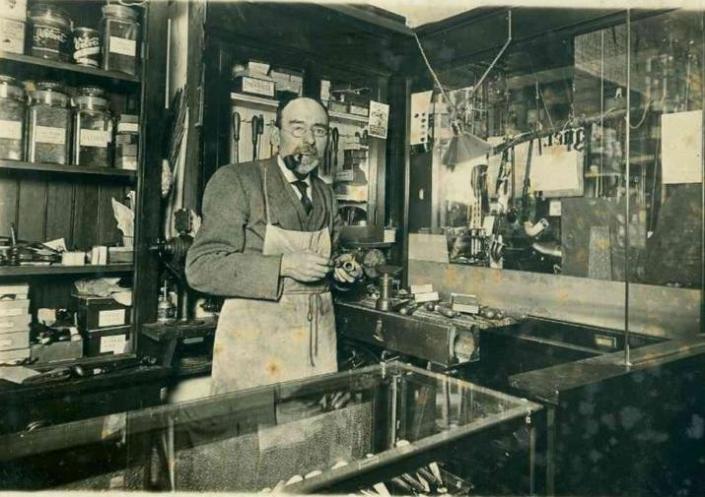

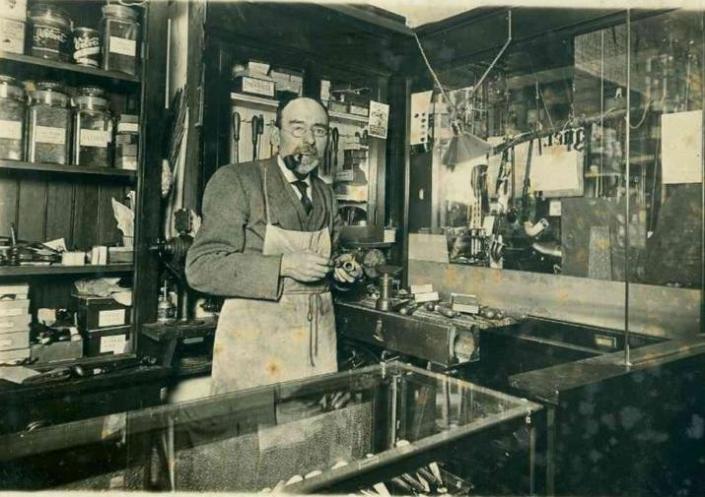

I love looking at old photos like the one above and crafting a story from the photo. This one evokes memories for me and others of like age of certain nostalgic pleasure cherished in the recesses of our minds. For some of you the idea of a shop like this is a piece from the lost past and one you might long for. Come with me to the shop and I will introduce you to the resident pipeman.

The shop is situated on a busy side street, just around the corner, in the heart of the business district of the city. It has large windows on the front of the narrow shop and there is a recessed entry door to the right of centre. As we come along the front of the shop you can see the display of pipes in one part of the window. They catch your attention if you have the soul of a pipeman. There are a wide range of pipes in the window – everything from Comoy’s and Barlings to ornate Meerschaums that marry form and function in beautiful ways. The number of pipes and tobacciana in the window speaks with promise of the rich treasures that await us when we walk through the door. But more interestingly, look at the man in the window with a pipe in his mouth and wearing a suit and tie under his work apron. He is bent over a buffer and methodically turns a pipe bowl that is pushed on the finger of one hand and held against the turning wheel of the buffer with the other. He is intent on his work and while we watch I tell you that his name is Andrew. He is a pipeman extraordinaire and is a fountain of pipe and tobacco knowledge. Once he finishes the buffing he looks up at us and gives us a nod. Let’s go inside and meet him.

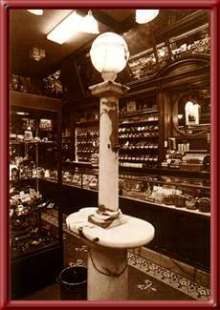

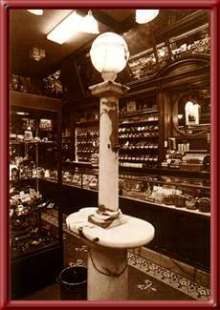

We push the front door open and a set of small bells hanging on the door chime our arrival. The rich looking oak cabinetry and counters give an aura of age to the room. The air is pungent with the fragrant mix of tobacco aromas – burned and unburned. On our left as we walk into the shop is the full service repair area where Andrew is working. Further down the display counter is a cash register. It is tall and ancient looking.The wall behind the counter is filled with jars of bulk tobacco each with an exotic name. The jars have small hand lettered cards that give a description of the components of the blend inside them. Next to these are shelves of assorted tins of tobacco for sale. Looking to your right you see that the opposite wall is lined with cabinets filled with pipes and underneath the display cases are rows of drawers. These cases extend the length of the wall. The drawers are waist high and above them are oak and glass cases, backlit to give a clear view of the pipes inside. There is so much to take in as you look around. Back to the other side again, just past the work counter is a humidor that houses cigars – not one of those modern walk in affairs but an old oak cabinet that is about 5 feet wide and 6 foot tall displaying the boxes of cigars. Looking down the centre of the shop you can see that at the far end there is a cozy sitting area with old well-polished black leather chairs and a chesterfield. There are side tables next to the chairs that hold matches, pipe cleaners and ash trays. Several older gentlemen are occupying the chesterfield and one of the chairs. They nod and lift a pipe to us as we walk in and then go back to their conversations and puffing.

After our look around the shop from the doorway I stop at the repair area to talk with Andrew and introduce you to him. “Hi Andrew, this is my friend Pat. I wanted to bring him in and introduce him to a taste of the past and to you of course. He is a relative new pipe smoker but he is learning quickly to enjoy the hobby.”

Without taking his pipe out of his mouth he welcomes you to his shop. He says, “Nice to meet you Pat, welcome to a taste of the past. Help yourself to the tobacco on the counter and the table in the back. Make yourself at home”. He turns to me and says, “I am just about finished working on the new stem your old Comoy’s Author”. He holds it up to show me – it is a fat stem that really works well with the nice piece of briar. The pipe looks finished to me but Andrew says, “I have to give it a good polishing and then you can have it back. Why don’t you take Pat back to the chairs, fire up a bowl and visit with the gents while I finish. When I am done I will bring it back to you and join you for a bowl or two.”

We head toward the back of the shop and the chairs, but our progress is slowed by the need to check out the shelves of pipes on display. I show you the drawers that house many more pipes. Each drawer is filled with many beautiful new pipes. At the end of the line just before the chairs, there is a display of estate pipes that Andrew has refurbished and is selling. There are some definite deals to be found there and I am sure one or two are calling my name like sirens. The first one I am drawn to is a nice older bent GBD Rhodesian with a tapered stem. The stem and bowl are flawless – no bite marks on the stem, no dents in the briar and the bowl is clean and ready for the new owner. I can’t pass this one up. “Look at this beauty Pat; I have to have this one,” I say as I show it to you. But you are already preoccupied and I see that your eye has been caught by an old Charatan Bell 33X shaped sandblast pipe. I watch, chuckling as you reach for it with the look of a new owner in your eyes. “That one has your name on it for sure, Pat,” I say. While you are looking I find another one that speaks to me – a nice older Loewe Lovat with lovely straight grain. Evidently I speak out loud, though I think I am talking to myself, “Two new pipes should do it for now – and I will have the old author back in my hands”.

Meanwhile I am stopped short in my reverie as I am brought back to the moment when you exclaim, “Wow, what a great place. I love the additions we are adding to our collections, Steve. I can’t wait to give them a try”. With that we head to the table in the midst of the gathering.

There on the table in front of the chesterfield are several open tins of tobacco. They are there for us to freely sample. We pick them up and sniff the fresh tobacco. I choose a nice stoved Virginia and you pick a rich English blend. We each pack our “new” pipe with the chosen tobacco and walk to the side of the sitting area where there is an old Electrolier. Andrew had told me that it was crafted from rare Mexican Onyx and is the last functioning model of its kind in the world. It was purchased in 1910 for $250.00 dollars and is a priceless piece of history. It has gas flames that are always burning and on the shelf around the centre column is a small box of cedar splints for lighting a pipe or cigar. We light our pipes with a splint. We tamp the bowls, relight and then extinguish the splints, dropping them in the bucket next to the lighter. We head back to the chairs and settle in for some great conversation and a smoke.

There on the table in front of the chesterfield are several open tins of tobacco. They are there for us to freely sample. We pick them up and sniff the fresh tobacco. I choose a nice stoved Virginia and you pick a rich English blend. We each pack our “new” pipe with the chosen tobacco and walk to the side of the sitting area where there is an old Electrolier. Andrew had told me that it was crafted from rare Mexican Onyx and is the last functioning model of its kind in the world. It was purchased in 1910 for $250.00 dollars and is a priceless piece of history. It has gas flames that are always burning and on the shelf around the centre column is a small box of cedar splints for lighting a pipe or cigar. We light our pipes with a splint. We tamp the bowls, relight and then extinguish the splints, dropping them in the bucket next to the lighter. We head back to the chairs and settle in for some great conversation and a smoke.

It is quiet for a while as we contentedly puff the sweet tobaccos and savour them. Slowly the conversation picks up again. Several of the regulars are there and we talk about the pipes we have picked up and the tobaccos smoked since our last conversation. One of the old gents, William has the most amazing collection of Dunhills that I have ever seen. I ask him, “William did you bring along any of your amazing Dunnies that you could show my friend Pat? I know he has never seen anything like them and that I never tire of looking at them.”

William reaches to the side table and picks up his leather pipe bag and opens it. He carefully takes out several of the pipes he had brought with him. He said, “I have these two older Shells that I brought along. The first is a 20’s vintage bulldog with an amazing blast. The second is a billiard that has a really craggy blast from the early 30’s. These are the only two I have with me other than the Bruyere in my mug (the one in his mouth is a beautiful old Bruyere billiard. I had seen it before and knew that it was a 1950’s vintage piece). Here have a look young feller.” With that he handed the pipes to Pat who sat on the edge of his seat puffing furiously as he held these pieces of history in his hands. He turned them over and over and the gents around the tables started to chuckle.

William said, “What do you think Pat? Ever seen anything like that pair?”

Pat replied, “No sir. I never even thought I would see something like them let alone have them in my hands. How long have you had them? Where did you pick them up?” He handed the little bulldog to me as he continued to examine the billiard and wait for the story that he knew was coming.

William laughed and said, “I picked the pair up at an antique shop many years ago now and have maintained the trust while they are in my hands. One day they will make their way into the next owner’s hands.” With that he waxed eloquent about how we hold pipes in trust, acting as stewards for the time that we live and then they pass them on to the next generation of pipemen who will also carry on the trust throughout their life times before passing them forward. Several of the other gents commented on the idea of the trust. This set a show and tell in motion as each of them pulled out their treasures and showed some of the pipes in their care. I sat there amazed as 80 year old William and several of the older gents gave us a glimpse of their collections and the incredible stories attached to each pipe. I looked over at Pat and noticed that he seemed to be lost in his own world as he continued to turn the pipes over in his hands checking out the blast and the flow of the old pipes. The stories just whirled around him.

Before we knew it our bowls had burned down to ash. Pat handed the two old pipes back to William and we carefully emptied the ash into the ashtrays, cleaned, repacked and relit our pipes. Pat commented, “What a great way to spend a day”. We sat and chatted about pipes and tobaccos with the other gents in the circle for the rest of the afternoon. The conversation waxed and waned as different ones left to relight their pipes or call it a day. Others came and took their places. The back of the shop was cloaked in a wonderfully smelling haze of pipe smoke. At one point in the afternoon the bell at the front of the shop tinkled as another of the regulars came in with a thermos of coffee to share with us. We laughed and commented as he put the thermos on the centre table and went to the back room and came out with some mismatched mugs, cream and some sugar. He went back and brought in a jar of teaspoons and set that on the table as well. Various ones poured a cup of coffee and thanked the newcomer for his gift. He winked at us and reached inside his shoulder bag and brought out a tin of cookies. We sipped coffee and munched the cookies, enjoying the treat. There was not much conversation going on while sipped and nibbled. We were too busy eating to interrupt the pleasure with conversation.

It was into the quiet reverie that the words, “Hey Steve, I have your pipe finished”. Andrew stepped into the circle of chairs with my pipe in his hands. “It passes my inspection. I gave it the final bit of buffing and it’s done for you. Load up a bowl and give it a smoke. I want to know what you think of it and if I need to make any adjustments for you before you take it home.” With that he handed me the pipe and took his place on the remaining chair in the circle. He tamped his pipe and puffed as he watched me take the pipe and load it up.

As the tobacco caught fire I said, “Thanks Andrew I am sure it is fine. I have never been disappointed with your work. But I will lay the pipe I have in my mouth down for a bit, load this one up and let you know.” The draw was as good as it had always been before I dropped the pipe and ruined the old stem. The feel in the mouth was perfect. The taper of the stem and the button shape were exactly to my liking. The bend in the stem made it hang exactly the way I remembered it had before. “Andrew, you got it perfect. I can’t think of a thing I would change.” I puffed contentedly on my old friend with a new stem.

Andrew chuckled, winked at me and puffed on his pipe. “We will see if you still think that after I give you the bill Steve.” He poured himself a coffee, stirred in some cream and entered into the stream of conversation around the circle. He sipped his coffee while holding his pipe in his hand. It seemed to me that I had never seen him without a pipe in his hand or his mouth. There were beads of coffee on his moustache as he set the cup down and reinserted his pipe in his mouth. He puffed gently and the pipe came back to life with a puff of smoke.

The afternoon went on like that for a while until, one by one; the gathering broke up with promises of see you next week. Soon Pat and I were the only ones left in the shop. “Well I guess we should go and get some work done before the day is over, eh Pat,” I said. So we made our way to the cash register to settle up for the “new” pipes and the repair bill. I took out my wallet and handed Andrew the payment. He chuckled when I exclaimed at how little the bill was. I am constantly amazed at the prices he charges for the fine work that he does. But then again I know he does it for the love of the pipe. We bid farewell and left shop with our pipes in our mouths. Andrew waved through the window to us and went back to work on his buffer.