Blog by Kenneth Lieblich

Welcome to another instalment of my Pipe Incident Reports. The idea, in general, is to provide a brief write-up – focusing on a particular pipe-restoration-related issue – rather than an entire restoration story. Today’s story is on the resolution of a very specific pipe repair, with some added challenges. I hope this blog post will be useful for those undertaking a similar repair.

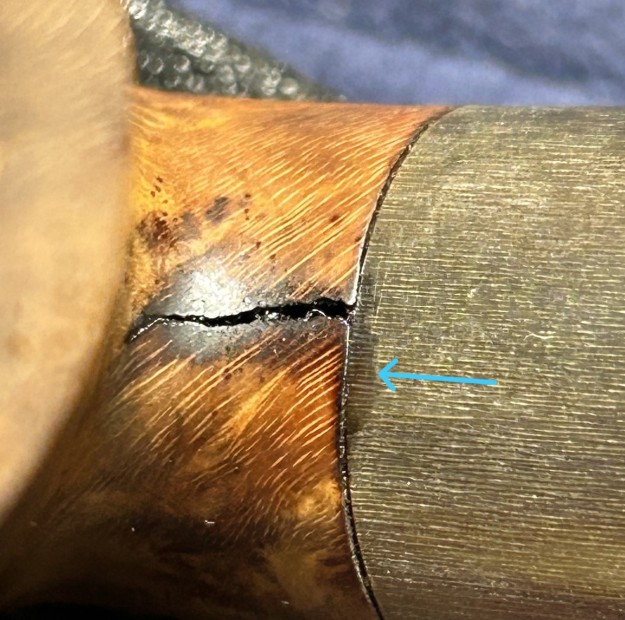

A couple of years ago, I restored a handsome Vauen Luxus 2013 for a friend and he’s smoked it with great gusto since then. In fact, you can see the story of its restoration here. By his own testimony, it’s a great pipe, smokes well, feels good in hand, etc. However, he noticed that a crack had appeared in the stummel and he wondered what I thought about it. This news sounded concerning, so I asked him to text me some photos and here is what he sent me:

Yikes! Not good at all. Aside from the obvious damage, I wondered if I had missed something the first time around. I went back in my files and closely examined all the photographs of the pipe from two years ago. There was no hint of any damage or potential for damage. Naturally, I asked Steve about it, and he posited that there must have been a pre-existing flaw in the briar. As it was hidden in the shank, there’s no way we could have known about it in advance. Whatever the cause, it was up to me to fix it. The photos show that, as the pipe was smoked, tobacco oils leeched through the crack and stained the wood. Furthermore, the horn shank extension was also being stained. That isn’t a good sign, but – first things first – let’s get the pipe clean.

Yikes! Not good at all. Aside from the obvious damage, I wondered if I had missed something the first time around. I went back in my files and closely examined all the photographs of the pipe from two years ago. There was no hint of any damage or potential for damage. Naturally, I asked Steve about it, and he posited that there must have been a pre-existing flaw in the briar. As it was hidden in the shank, there’s no way we could have known about it in advance. Whatever the cause, it was up to me to fix it. The photos show that, as the pipe was smoked, tobacco oils leeched through the crack and stained the wood. Furthermore, the horn shank extension was also being stained. That isn’t a good sign, but – first things first – let’s get the pipe clean.

I did my usual thing: reaming out the bowl, cleaning the tars and oils with isopropyl alcohol, etc., and scrubbing the insides with a cleaner and some tube brushes. I also used a dental pick to remove as much debris as possible from the crack.

I did my usual thing: reaming out the bowl, cleaning the tars and oils with isopropyl alcohol, etc., and scrubbing the insides with a cleaner and some tube brushes. I also used a dental pick to remove as much debris as possible from the crack.

Here it is looking clean, albeit a bit the worse for wear:

Here it is looking clean, albeit a bit the worse for wear: Fixing a crack like this isn’t the end of the world: it usually involves drilling micro-holes at both ends of the crack and then sealing it. In this case, its location added some considerable challenges. One end of the crack was adjacent to the horn shank extension and I didn’t want to risk drilling there and potentially damaging the horn. The other end of the crack was in the trickiest location to access – right in the lowest point of the bend in the stummel.

Fixing a crack like this isn’t the end of the world: it usually involves drilling micro-holes at both ends of the crack and then sealing it. In this case, its location added some considerable challenges. One end of the crack was adjacent to the horn shank extension and I didn’t want to risk drilling there and potentially damaging the horn. The other end of the crack was in the trickiest location to access – right in the lowest point of the bend in the stummel.

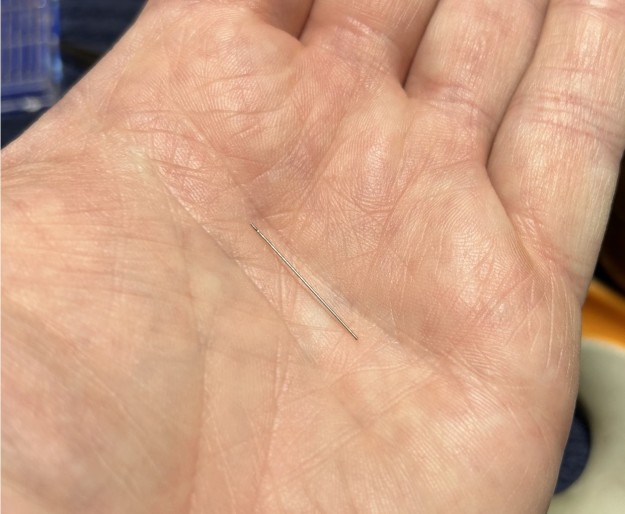

As usual, I used the smallest micro-drill bit I owned. This drilling is done to stop the crack from extending on its own. Before I stated drilling, however, I covered everything around the crack with some clear hockey tape. I wanted to prevent my drill from rubbing against the wood or horn, or potentially gouging anything during this rather precarious procedure. With great care, I managed to successfully drill the hole through the briar.

I then plugged the shank with pipe cleaners coated in petroleum jelly, as it prevents the soon-to-be-applied cyanoacrylate adhesive from adhering to the insides (in case it drips inside). I created a thin bead of adhesive along the damaged area and ensured that it was well filled. I left the adhesive to cure and came back to inspect my work. It looks like it worked well. This sort of restoration will never be invisible, but will ensure a very strong repair for the future.

I then plugged the shank with pipe cleaners coated in petroleum jelly, as it prevents the soon-to-be-applied cyanoacrylate adhesive from adhering to the insides (in case it drips inside). I created a thin bead of adhesive along the damaged area and ensured that it was well filled. I left the adhesive to cure and came back to inspect my work. It looks like it worked well. This sort of restoration will never be invisible, but will ensure a very strong repair for the future. Once again, the location of the repair proved challenging as I set about sanding down the excess adhesive with needle files and then using my Micromesh pads over the whole stummel.

Once again, the location of the repair proved challenging as I set about sanding down the excess adhesive with needle files and then using my Micromesh pads over the whole stummel.

I added some Before & After Restoration Balm and worked that into the wood. I also took it to the buffer for some wax, but the photos below were taken before that. Thanks so much for joining me on this tricky repair. I hope you enjoyed reading this instalment of the Pipe Incident Report – I look forward to writing more. If you are interested in my work, please follow me here on Steve’s website or email me directly at kenneth@knightsofthepipe.com. Thank you very much for reading and, as always, I welcome and encourage your comments.

I added some Before & After Restoration Balm and worked that into the wood. I also took it to the buffer for some wax, but the photos below were taken before that. Thanks so much for joining me on this tricky repair. I hope you enjoyed reading this instalment of the Pipe Incident Report – I look forward to writing more. If you are interested in my work, please follow me here on Steve’s website or email me directly at kenneth@knightsofthepipe.com. Thank you very much for reading and, as always, I welcome and encourage your comments.