This article on Alan’s blog was one in which I was particularly interested. I had recently purchased and estate pipe that was advertised as carefully restored only to find that both the externals and the internals had not been truly cleaned. It seemed that the pipe had only received a good buff and polish and that was it for the cleanup and restoration. I found it irritating to say the least that I had purchased a pipe that cost me enough that it should have been cleaned and wasn’t but that the damage to the exterior had also not been dealt with. In this article Alan speaks about the methodology used at reborn briar to clean estate pipes. It also provides a check list for the hobbyist when he wants to clean up the estate pipes discovered on a pipe hunt. Thanks Alan. The original article can be read at http://estatepipes.co.uk/pipeshop/blog/its-all-about-the-aesthetics-isnt-it.html. Also be sure to check out other articles on the blog and visit Alan’s online shop.

This article on Alan’s blog was one in which I was particularly interested. I had recently purchased and estate pipe that was advertised as carefully restored only to find that both the externals and the internals had not been truly cleaned. It seemed that the pipe had only received a good buff and polish and that was it for the cleanup and restoration. I found it irritating to say the least that I had purchased a pipe that cost me enough that it should have been cleaned and wasn’t but that the damage to the exterior had also not been dealt with. In this article Alan speaks about the methodology used at reborn briar to clean estate pipes. It also provides a check list for the hobbyist when he wants to clean up the estate pipes discovered on a pipe hunt. Thanks Alan. The original article can be read at http://estatepipes.co.uk/pipeshop/blog/its-all-about-the-aesthetics-isnt-it.html. Also be sure to check out other articles on the blog and visit Alan’s online shop.

The aesthetics of a restored estate pipe are an important factor. How the pipe looks on the outside is where most restorers concentrate their efforts. Especially if selling your pipes on the online marketplace, you will want the pipes to look good in photographs. These pictures are what the buyer sees, and will most likely base his opinion on whether to buy the pipe or not. I get tons of emails from satisfied customers after they receive their pipes about how good they look – that they are like a brand new pipe. But these are just external aesthetics, which is the easiest part to achieve

The aesthetics of a restored estate pipe are an important factor. How the pipe looks on the outside is where most restorers concentrate their efforts. Especially if selling your pipes on the online marketplace, you will want the pipes to look good in photographs. These pictures are what the buyer sees, and will most likely base his opinion on whether to buy the pipe or not. I get tons of emails from satisfied customers after they receive their pipes about how good they look – that they are like a brand new pipe. But these are just external aesthetics, which is the easiest part to achieve

However, to me the most important part of any estate pipe restoration lies not in the external aesthetics, but in the internal functions, cleanliness and sterilisation of the pipe. This is the point that most pipe restorers miss. You have to be prepared to roll your sleeves up and get your hands dirty to accomplish this task properly. I am amazed at the number of so called restored estate pipes that I get in from eBay that look wonderful on the outside, but have had no attention paid to the inside of the pipe – and I have to start the cleaning process from scratch.

The following is how I prepare the inside of a pipe to make it pleasurable and safe for a new smoker.

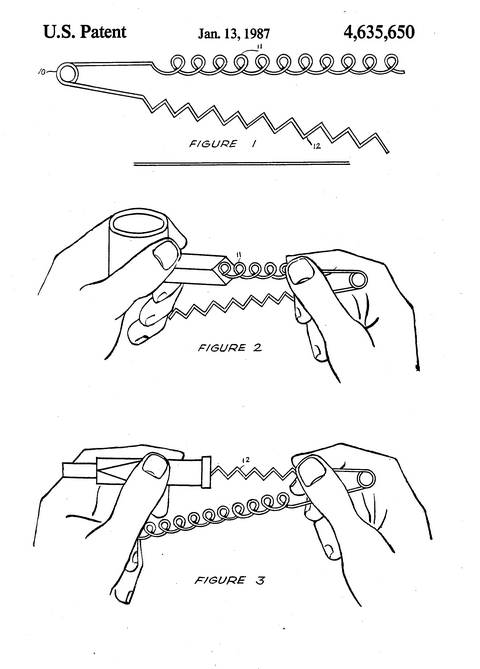

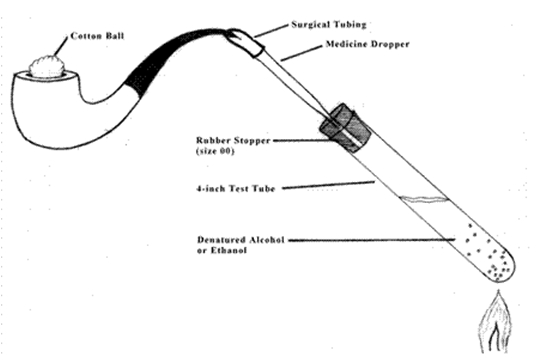

The Stem: It is amazing the number of pipes I receive that seem to have never had a pipe cleaner put through the stem. I have had pipes where the stem is completely blocked with tar. When I soak the stem in a bath to soften any outside oxidation, this also helps to start to soften any internal tars. A final bath in hot water and soap helps this process along. The inside of the stem will first be scrubbed with bristle pipe cleaners, and then the stem sill receive a hot alcohol retort. This will help to soften any remaining stubborn tar in the stem. Continual scrubbing with both bristle and normal pipe cleaners using alcohol follows until they come out clean. Particular attention is given to the sides of the slot and any filter chambers, as these are the places where most tars gather. Finally the stem airway and slot is polished internally to allow for smooth transition of the smoke. This provides both a clean and sterilised mouthpiece to the pipe.

The Bowl Chamber: All excess cake and carbon are removed. If you are restoring one of your own pipes, it is advisable to leave a thin layer of cake inside. The cake in a pipe will retain the oils of the smoked tobaccos. As I don’t know what either the previous smoker or the new smoker’s preferred tobacco is, I do not want to leave any ghosting in the pipe which is why I remove all remnants of carbon. The inside of the bowl is then hand sanded with 600 grit wet and dry paper to leave a smooth finish. Removing all the cake also lets me examine the inside of the chamber for defects.

The Airway & Draft Hole: Thick tars accumulate in the airway of a pipe, especially if they are not cleaned regularly after every smoke. I receive a number of pipes where the airway is completely blocked and wonder how the previous smoker was able to smoke the pipe at all. Pipes in this condition require the airway to be initially hand drilled using the correct size bit to remove this solid build up, as they will not even pass a pipe cleaner. After this the shanks are scrubbed with shank brushes and bristle pipe cleaners dipped in alcohol. This will never entirely remove all the residue on the first clean. The bowl is then given a hot alcohol bath using our special process. This will soften any remaining residue and the airway is again scrubbed with shank brushes and pipe cleaners until normal pipe cleaners come out clean. Finally the bowl receives a final hot alcohol retort to leech out any remaining flavours and totally sanitise the pipe leaving it clean and fresh.

The Shank: To me this is the most vital area of cleaning, yet it is the most disregarded area by the majority of restorers. The shank gathers a cake like build up, especially between the end of the airway and tip of the tenon. Given that this build up is made up from a mixture of tobacco tars and juices, ash and human saliva – it is vital that this is removed before the pipe is passed on to a new smoker! No amount of rubbing with Q-tips and alcohol will remove this hardened build up. In fact the cotton tips may come out looking clean leading the restorer to think that the area is ready for use – wrong! We use a specially adapted tool to scrape out this cake like residue. The first attempt at this will not remove all remnants. Only after the pipe bowl has been given its initial special process hot alcohol bath, will this soften the remaining residue and the shank is scraped out again. The shank can now be scrubbed out with a shank brush and Q-tips dipped in alcohol until they come out clean. Finally the stummel will be given a hot alcohol retort which will remove any remaining oils and leave the pipe clean, fresh and sanitised. The picture shows a before and after shot of a recently restored 1906 Peterson Patent pipe, displaying what a properly restored shank should look like.

At Reborn Briar, we pride ourselves on both the appearance of our restored pipes and the attention to detail of the internal mechanics. Using our special processes means that you will receive a restored pipe that will smoke as clean and fresh as a new pipe and provide you with many years of smoking pleasure ahead.