Blog by Steve Laug

On my recent Idaho trip my brother and I went on a pipe hunt through quite a few antique malls. One of them in particular yielded some great finds. The first of these I worked on was the bent diamond shank cob pipe that I wrote about earlier. The next one I worked on was a small Medico Meerschaum Straight Bulldog. I honestly had no idea that Medico made meerschaum pipes so it was a surprise to me. It was in pretty decent shape with a little buildup on the rim and a light cake in the bowl. The meer was clean except for a few small nicks in the sharp edges of the diamond shaped shank and some small scratches on the top surface of the rim. The single ring around the bowl below the cap is in perfect shape with no nicks or dings. It had dust and some grit in the bottom of the ring but otherwise the edges were sharp. The stem has a reverse tenon set up with the tenon permanently inserted in the shank and a permanently inset stinger/filter apparatus that sits in the bottom of the bowl like a grate in a fireplace. The 14K gold band had light scratches and is stamped MEDICO over 1/30 14K RGP. There are no other marking on the pipe or shank. The stem is in decent shape with light tooth chatter on the top and underside near the button and is stamped with an M in a shield. From my research the Medico Meerschaum pipes were carved in Austria by Strambach. This one is stellar.

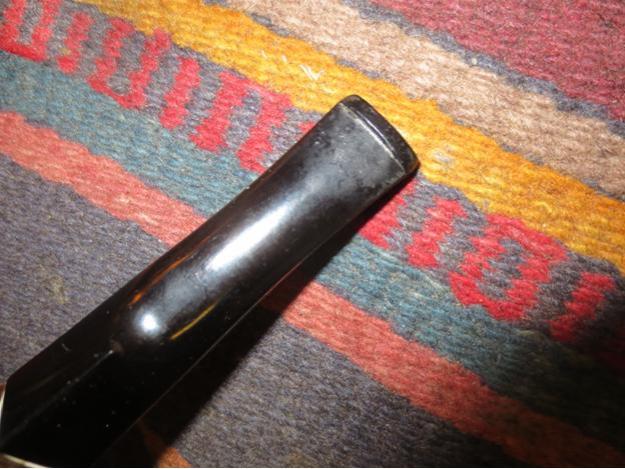

The next three photos show close up views of the rim and the top and bottom sides of the stem. The top of the rim was dirty and had a slight buildup of tars on the back side and some scratches on the rim top. The stinger apparatus in the bottom of the bowl was darkened and caked as well. The bowl had a light cake buildup that would need to be reamed. The stem had tooth chatter on the top and underside.

The next three photos show close up views of the rim and the top and bottom sides of the stem. The top of the rim was dirty and had a slight buildup of tars on the back side and some scratches on the rim top. The stinger apparatus in the bottom of the bowl was darkened and caked as well. The bowl had a light cake buildup that would need to be reamed. The stem had tooth chatter on the top and underside.

The next photo shows the stem removed from the shank and the Medico paper filter that was in the shank. It also shows the reverse tenon that is inserted in the shank.

The next photo shows the stem removed from the shank and the Medico paper filter that was in the shank. It also shows the reverse tenon that is inserted in the shank. I scrubbed the rim with a cotton pad and saliva to clean off the tars on the surface. I also sanded it with a micromesh sanding pad. I also sanded the sharp edges of the diamond shank to smooth out the nicks and scratches.

I scrubbed the rim with a cotton pad and saliva to clean off the tars on the surface. I also sanded it with a micromesh sanding pad. I also sanded the sharp edges of the diamond shank to smooth out the nicks and scratches.

I reamed the bowl with a PipNet pipe reamer to remove the cake from the bowl. I used a cotton swab to clean off the stinger extension in the bottom of the bowl.

I reamed the bowl with a PipNet pipe reamer to remove the cake from the bowl. I used a cotton swab to clean off the stinger extension in the bottom of the bowl.

I cleaned out the airway in the stem with pipe cleaners, cotton swabs and alcohol.

I cleaned out the airway in the stem with pipe cleaners, cotton swabs and alcohol. I worked on the stem to remove the tooth chatter on the surface of the top and bottom near the button. I sanded it with 220 grit sandpaper to remove the chatter and then sanded it with a medium and a fine grit sanding sponge. I moved on to use micromesh sanding pads – wet sanding it with 1500-2400 grit pads and then rubbing it down with Obsidian Oil. I dry sanded with 3200-4000 grit pads and rubbed it down again. I finished sanding it with 6000-12000 grit pads and gave it a final coat of Obsidian Oil. I let it dry before taking it to the buffer.

I worked on the stem to remove the tooth chatter on the surface of the top and bottom near the button. I sanded it with 220 grit sandpaper to remove the chatter and then sanded it with a medium and a fine grit sanding sponge. I moved on to use micromesh sanding pads – wet sanding it with 1500-2400 grit pads and then rubbing it down with Obsidian Oil. I dry sanded with 3200-4000 grit pads and rubbed it down again. I finished sanding it with 6000-12000 grit pads and gave it a final coat of Obsidian Oil. I let it dry before taking it to the buffer.

I buffed the stem and bowl lightly with Blue Diamond Plastic polish on the wheel. A light touch is essential when buffing these nylon stems. It is very easy to melt them and make a mess. The finished pipe is shown in the photos below. It is a beautiful pipe.

I buffed the stem and bowl lightly with Blue Diamond Plastic polish on the wheel. A light touch is essential when buffing these nylon stems. It is very easy to melt them and make a mess. The finished pipe is shown in the photos below. It is a beautiful pipe.