I have been smoking this Bill Boyle chubby apple that I picked up from him for quite a while now and thought it was time to write up a review. This is the second pipe that I have purchased from Bill and I have found both of them to be consistently good smokers. Bill moved from pipe refurbishing and cobbery (crafting handmade cob uniques) to pipe making a few years back and his craftsmanship is progressing quickly. The first pipe I bought from Bill several years back smoked incredibly well, as the internal mechanics were perfect. But it had a thick stem and button that I found uncomfortable. In this pipe he has progressed on the shaping of stems and buttons to the point that it is very comfortable. I think one of the things I appreciate about Bill is that he is always learning and improving.

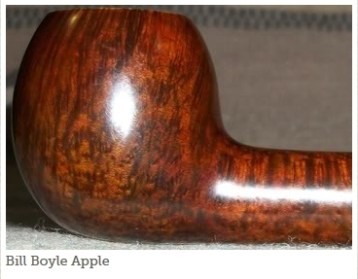

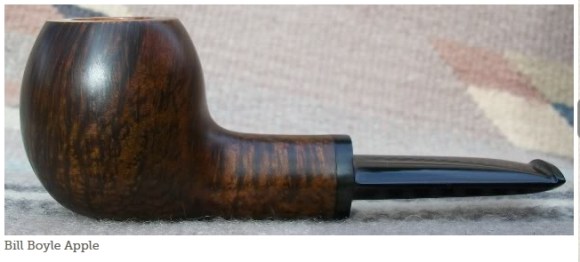

The latest pipe I purchased from Bill was a Chubby Apple.

The dimensions for this pipe are as follows:

Length: 5 inches

Height of the bowl: 1.75 inches

Size of the chamber: .75 inch diameter and 1.5 inches in depth

Drilling through the shank: 5/32inches

Drilling in the stem: 5/32″ to tapered toward the button and funnelled at the button

Weight: 2.0 ounces

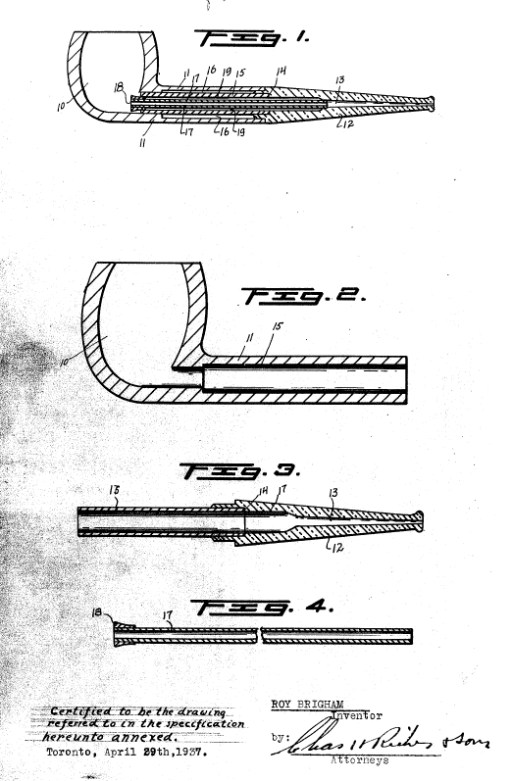

The mechanics of this pipe are well done – as are those of my previous Bill Boyle pipe. He has really mastered the drilling and internal design for his pipes. The bowl interior is clean and smooth when it arrived. He uses no bowl coating so the interior of the briar is visible. This one is a clean piece of briar with no surprises (at least on the surface). The airway is centered in the bottom of the bowl as it should be. There are no ragged edges or pieces left behind by the drill bit. The airway is smooth when examined with a light. It is smooth throughout the shank with no ragged edges. The transition from the airway to the mortise is also smooth and clean. The airway in the stem tapers toward the button and ends in a smooth funnel at the button. The button on Bill’s pipes used to be too thick for me and I would file them down to the size I like when they arrived. I mentioned that once to Bill and he made this button to exactly the specs that I spelled out over the phone. The slot in the airway is also smooth and clean with no ragged edges. It is also centred in the button – something that I used to take for granted but have learned to pay attention to on the pipes I buy and the ones I restem.

The externals – shaping, finish, stem and feel of the pipe are excellent. I like the compactness of Bill’s apple shape. My other pipe is also an apple – ¼ bent. He did a great job cutting it to maximize the grain and highlight the beauty of the piece of briar. The feel in the hand is perfect for me as I find the apple shape a very comfortable shape to smoke. The finish is nicely done. His staining of the pipe is even and smooth with no fading or light spots on the pipe. The contrast of the undercoat with the brown finish coat makes a nice looking pipe. The stain on the undercoat makes the grain really stand out and the overcoat sets it off very nicely. There is one flaw in the bowl on the front of the pipe. It is visible but does not affect the smoking ability of the pipe (see the picture below). The flaw is not terribly deep but Bill chose to stop sanding so that he could maintain the shape that he had chosen for this pipe.

The saddle stem is hand cut German ebonite and is comfortable in the mouth. For me some of Bill’s earlier pipes had a more drastic slope on them and thus were not as comfortable in my mouth. I found them hard to hold in my jaw. The slope on this one is more gradual. The flat blade of the stem is cut well and is also a good thickness for the look of the chubby bowl and shank. Bill has tapered the edges to meet and create a midline on both sides of the stem. Nicely done! The finish on the stem is also very good. There are no file marks or scratches in the finish. It is a smooth finish and he has polished it a glassy shine. The fit of the saddle to the shank is also well done. There is no gap between the stem and the shank of the pipe. The thin saddle is a feature that I really like on this pipe – it gives is a unique look. The fit in the tenon is snug and smooth.

I have been smoking the pipe now for long enough to know that it is a smoking machine. It was not terribly hard to break in and after a few bowls the bowl had begun to form a thin cake. I smoke primarily Virginias and Virginia Perique tobaccos in this pipe and it delivers a clean full bodied taste each smoke. The draught on the pipe is quite effortless as it is an open drilling. The briar warms nicely in the hand but does not get hot. If you have not worked with Bill to have him make a pipe for you or have not picked one up on his website http://billboylepipes.weebly.com/ you should give them a try. If your experience is anything like mine you will not stop with one pipe.