Blog by Doug Bisbee

Doug has been a reader of rebornpipes for a while now and he emailed me some work he had done fitting/converting a bowl from a Streamliner Metal Pipe bowl to fit a Kirsten Pipe. He sent me a series of photos of incredibly shiny bowls that are converted to fit a Kirsten just to show me what could be done. I was so impressed with the quality of his work that I wrote and asked him to put together a blog on how he achieved the shine and how he did the conversion of any metal bowls to fit a Kirsten barrel. He sent me the following step by step procedure using the bowl from a Streamliner. It is a pleasure to have Doug write this for rebornpipes and share not only his expertise but also his work. Doug sent me a step by step procedure that I have included below with a few of my own details. If you have a metal pipe or bowl you would like him to convert, you can email Doug at the following email address: 6131doug@gmail.com, and he will do the conversion for you. He also has bowls for sale that he has already converted.

STEPS TO CONVERTING A METAL BOWL

STEP#1 Bowls that are held in place with a center screw are the ones that work most easily. On this Streamline used to illustrate the process the bowl was held in place on the metal base with a center screw. The screw is not the same size as the one used to hold a Kirsten bowl on the base. Remove bowl from the shank of the Streamliner pipe a with screwdriver.

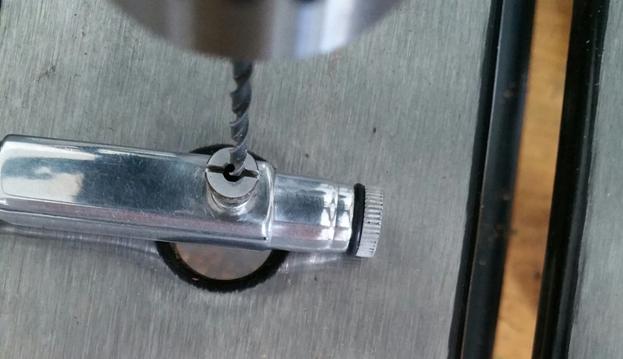

STEP #2 To begin the process of fitting the Streamliner bowl to a Kirsten base the hole in the bottom of the metal bowl needs to be enlarged with a letter “O” drill bit.

STEP #2 To begin the process of fitting the Streamliner bowl to a Kirsten base the hole in the bottom of the metal bowl needs to be enlarged with a letter “O” drill bit.

STEP #3 Once the hole has been enlarged in the metal bowl with the “O” drill bit the hole in the briar bowl also needs to be enlarged with a 1/4-inch drill bit. (I do this by hand). STEP #4 The bowl in the photo below is from a different metal bowl but the principle is the same. After drilling the bottom of the bowl to open the screw hole it is time to sand and refinish the top of the bowl rim (I use Tung oil).

STEP #4 The bowl in the photo below is from a different metal bowl but the principle is the same. After drilling the bottom of the bowl to open the screw hole it is time to sand and refinish the top of the bowl rim (I use Tung oil). STEP #5 I order Kirsten adapters from Kirsten in Seattle (Kirsten Pipe Company, 910 Lenora Street, Suite 156, Seattle, WA 98121) or they can be ordered online on their website at this link: https://www.kirstenpipe.com/page_accessories.shtml. You will need both the adapter and a long screw.

STEP #5 I order Kirsten adapters from Kirsten in Seattle (Kirsten Pipe Company, 910 Lenora Street, Suite 156, Seattle, WA 98121) or they can be ordered online on their website at this link: https://www.kirstenpipe.com/page_accessories.shtml. You will need both the adapter and a long screw.

I like to polish the Kirsten bowl adapter so it matches the shine of the finished bowl. I do the buffing on a buffing wheel (spiral sewn & air flex) with brown compound. I also polish the outside of the metal bowl on the wheel.

A neat trick that I use to polish in the grooves of the bowl is put the end of a pipe cleaner in the vice, smear metal polish on the pipe cleaner and hold the other end of the pipe cleaner in your hand pulling it tight and keep rubbing the bowl over and over it with the pipe cleaner in the groove of the bowl… it takes a long time but works very well. I use Mothers Polishing Compound for this.

A neat trick that I use to polish in the grooves of the bowl is put the end of a pipe cleaner in the vice, smear metal polish on the pipe cleaner and hold the other end of the pipe cleaner in your hand pulling it tight and keep rubbing the bowl over and over it with the pipe cleaner in the groove of the bowl… it takes a long time but works very well. I use Mothers Polishing Compound for this.

STEP #6 After the polishing the bowl is ready to fit on the Kirsten Pipe base.

STEP #6 After the polishing the bowl is ready to fit on the Kirsten Pipe base.

STEP #7 After polishing the bowl and adapter I put the Kirsten adapter on bottom of bowl. I put briar bowl in metal bowl and attach the adapter to the Kirsten Base from the inside of the bowl using the long Kirsten screw.

STEP #7 After polishing the bowl and adapter I put the Kirsten adapter on bottom of bowl. I put briar bowl in metal bowl and attach the adapter to the Kirsten Base from the inside of the bowl using the long Kirsten screw.

Now comes what I think is the really cool part!

Now comes what I think is the really cool part!

STEP #8 I want the bowl to be interchangeable on either the Kirsten or the original base so I need to modify the Streamliner Base to take the new Kirsten long screw. To do that takes several steps that in essence involve creating a raised platform to accommodate the Kirsten Bowl adapter that you installed on the meal Streamliner Bowl. I put the original Streamliner bowl screw back in the shank of the Streamliner pipe base and drill the airway out using a #21 drill bit. I am careful to drill only 3/16 of an inch deep. STEP #9 Once the hole is drilled I use a 10-32 tap to tap 1/8-inch-deep threaded hole into the top of the screw.

STEP #9 Once the hole is drilled I use a 10-32 tap to tap 1/8-inch-deep threaded hole into the top of the screw. STEP #10 I use a grinder to grind off the top of the screw to remove the head. What remains is a collar that provides the base for the Kirsten adapter rest on and accommodate the long Kirsten screw.

STEP #10 I use a grinder to grind off the top of the screw to remove the head. What remains is a collar that provides the base for the Kirsten adapter rest on and accommodate the long Kirsten screw.

STEP #11 With the collar in place and the newly tapped threaded insert the original Streamliner bowl will screw right on to the original base! If you didn’t look to closely you wouldn’t even know it had been converted!

STEP #11 With the collar in place and the newly tapped threaded insert the original Streamliner bowl will screw right on to the original base! If you didn’t look to closely you wouldn’t even know it had been converted!  STEP #12 With the conversion done to both the bowl and the original Streamliner base, now any Kirsten bowl will fit onto your Streamliner pipe and your Streamliner bowl will fit onto any Kirsten pipe!

STEP #12 With the conversion done to both the bowl and the original Streamliner base, now any Kirsten bowl will fit onto your Streamliner pipe and your Streamliner bowl will fit onto any Kirsten pipe! STEP #13 The beauty of the process is that it can be done to almost any metal bowl on any of the pipes you come across. It takes a little ingenuity, but the modifications or conversion is not only possible but doable. The only thing that remains is to enjoy your new pipe!

STEP #13 The beauty of the process is that it can be done to almost any metal bowl on any of the pipes you come across. It takes a little ingenuity, but the modifications or conversion is not only possible but doable. The only thing that remains is to enjoy your new pipe!

The following photos show some of the bowls I have converted. Once again if you have a metal pipe that you would like me to convert for you so that the bowls can be used interchangeably on the original base and on a Kirsten just email at the address above. We can talk about prices and time lines. I would love to do some work for you. Metal pipes are my passion and I love to smoke them. Thanks for looking and I can’t wait to hear from you.

The following photos show some of the bowls I have converted. Once again if you have a metal pipe that you would like me to convert for you so that the bowls can be used interchangeably on the original base and on a Kirsten just email at the address above. We can talk about prices and time lines. I would love to do some work for you. Metal pipes are my passion and I love to smoke them. Thanks for looking and I can’t wait to hear from you.