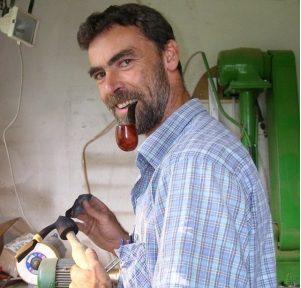

For those who are unfamiliar with Alan Stevenson, a pipemaker from Wisconsin, I am including some information regarding him taken from Pipedia. I think it will be helpful for you to get a feel for the pipe maker before you read my review of his pipe.

“Alan Stevenson is known for his high quality handmade pipes in classic shapes. His trademark hand cut Cumberland stems are a favorite among those who own one or more of his finely crafted pipes. His pipes have a reputation for being some of the best smoking pipes available and their quality is well above their selling price. Alan is a rather modest individual when it comes to his pipe crafting skills, as evidenced from his quote below.” – Pipedia

Quoted from the Alan himself: “My Name is Alan Stevenson and I live in Wausau, WI. I am a very late bloomer for a pipe maker. Have been smoking a pipe since college in 1966. I have always wanted to try making a pipe, so after 30+ years in industry I have retired to my little corner of the garage. Pipemaking for me has really involved a steep learning curve which I have only begun to climb. My background is math, physics and chemistry; I had never touched a wood or metal lathe in my life. Starting at nearly 60 is tougher than most would think.

In 2004 I had tried my hand at a couple of kits from Mark Tinsky and enjoyed working on them. So I paid the kindly Mr. Tinsky a visit in Helena. Mr. Rad Davis was there at that time as well and for a few days I had the privilege of learning a little about pipemaking from these two gentlemen. I left Helena with a couple of pipes, a bunch of briar and some stems and returned to finish working on them in my shop. About 2 years ago I got my nice metal lathe and set about learning how to hand cut a stem. If I ever learn to do that correctly then I might consider that I am a pipemaker. Till that time I am still learning.” – Pipedia

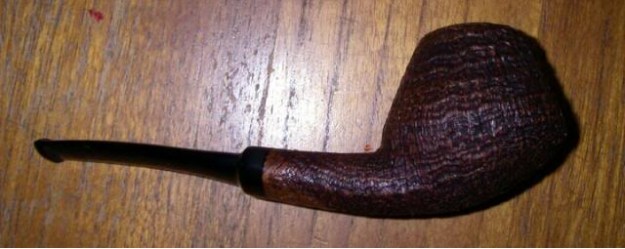

Several years ago I contacted Alan regarding a commissioned pipe that I wanted him to make for me. Earlier I had been gifted one of Alan’s rejects and had stemmed it myself and I loved the finish and feel of that pipe. He had done a great job in laying out the cut of the pipe with the grain of the briar on the reject stummel I had so I wanted to see his magic on a full pipe. I gave him a call and asked if he would carve a pipe for me. My request was pretty simple in that what I wanted was roughly an apple shaped pipe that had a smooth finish. I did not specify colour or finish or even the lay of the grain. I also did not specify a shank extension or the wood that he would use in it. I pretty much left all of the artistry up to Alan to work his magic.

When the pipe arrived and I have to tell you the shape and finish went beyond what I had in mind when I commissioned it from Alan. It was and is beautiful. The length of the pipe is 5 inches and the bowl height is 1 5/8 inches. The bowl diameter is 1 1/4 inches. The chamber diameter is 7/8 inches and depth is 1 1/4 inches. The lay of the shape to the grain is superb. The sides bear a mix of straight grain and flame. There are spots on the front and back of the bowl which have mediocre grain but Alan did a good job of working that into the finish. The rim, the bottom of the bowl and the top and bottom of the shank have some nice birdseye grain. There is one slight flaw in the briar at the front toward the bottom of the bowl that he blended into the grain of the briar nicely. It looks to me that he used a dark brown stain on the undercoat to highlight the grain and then a tan or light brown stain to cover that and give the pipe a warm hue. He made a shank extension that combines a thin band of Cumberland and a wider band of olive wood. The olive wood is also stained with the tan stain and looks good. The stem is Cumberland and matches the band. The overall flow of the bowl and shank is brilliant and the colours are beautifully matched from rim to the end of the shank.

Alan did an excellent job on the inner mechanics of the pipe with drilling that is perfectly executed from the shank and into the bowl – coming out exactly centre in the bottom of the bowl. The airway and the inside of the bowl were very smooth with no rough spots left by the drill bit in the bowl or shank. There was no bowl treatment or coating so just a good smooth briar. He had sanded the inside of the bowl and there were no hidden flaws or surprises.

The stem itself is hand cut out of Cumberland. It has a gentle taper from the shank to the button. It has a slight bend to it that gives it a stylized look. Alan did a great job shaping the stem and capturing a shape that really works with this pipe. The stem is nicely finished with no marks or scratches in the Cumberland. The tenon is integrated with the stem and cut into the Cumberland. The fit in the mortise and against the shank is snug. He countersunk the end of the mortise to make for a snug fit of the stem to the shank. There appears to be a slight gap where it meets the shank but as I examine it with a light I think that it is a problem with the stem being slightly larger in diameter than the shank. The end of the tenon is funneled slightly for a smooth transition from the mortise when it is in place. There is a very minimal gap between the end of the tenon and the base of the mortise. The airway is smooth from the entry of bowl airway all the way to the button. The draught is unrestricted and open from the bowl to the tip of the stem. The button is perfect to my liking and very comfortable in the mouth and teeth. The edge is narrow and well shaped. The slot in the mouthpiece is fanned out and is oval in shape. The airway is thus consistent in size from the tenon to the slot. There is no whistle or noise when the air is drawn through the pipe.

The overall construction of this pipe is very well done. It is light in the hand and in the mouth. It is well balanced and has a shape that fits well in my hand. There are some slight details in the finish of the pipe that in no way affect its smoking ability. They are truly cosmetic in nature. I list them at this point only because to me they are there and others will see them. The first involves the shank extension. There are some spots on the underside of the shank where the epoxy squeezed out between the Cumberland and the olive wood. The second involves the fit of the stem being slightly off. There appears to be gap at the junction as noted above. However, in examining the stem and shank and measuring the diameter of each it is clear that the problem is not a gap but that the stem is slightly larger in diameter than the shank. This could easily be corrected but I have not done so yet. The third issue may appear to be a finicky one to be sure, but it is there nonetheless. The Cumberland of the band and the stem seem to come from different pieces of stock and thus the lines/striations do not line up. This issue does not bother me but some would find it troublesome. Apart from those very simple cosmetic issues the pipe is well made and is a smoking machine.

I have been smoking it for a few years now and after breaking it in with what has become my first love in tobacco, McClelland’s 5100 it has become a great Virginia smoking pipe. It has always delivered a good smoke from the first smoke to the present. It draws well; the lighting has never been a problem. It seemed to take very little time to break it in and continues to be an effortless smoke.

Thanks Alan for delivering a well made pipe at a great price. It remains a very good smoking pipe through the years since I purchase it. I do not know whether Alan continues to craft his fine handmade pipes but if he does they are worth considering. I see them come up on EBay periodically and one day I will pick another one up. If anyone knows if he continues to make pipes I would love to hear from them. You cannot go wrong with a Stevenson Handmade Pipe.