By Al Jones

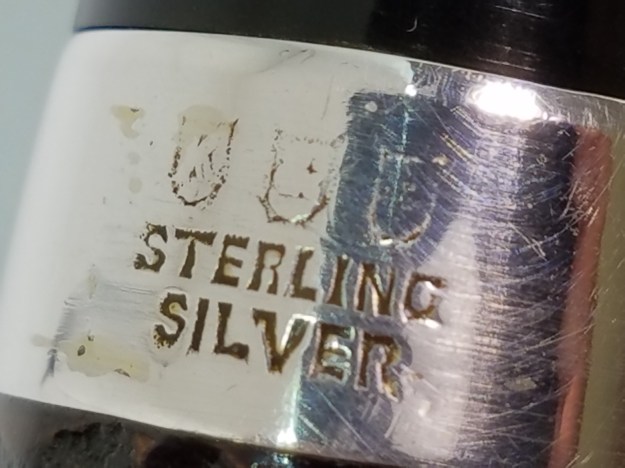

This 409 Bulldog Golden Grain found its way to my work bench this weekend. The 409 is the most popular Comoy’s bulldog, but I’ve only worked in three versions of this shape in the past seven years. It’s not certain when the Golden Grain entered the Comoy’s line up. The COM and three-piece C stem logo were used from 1946 to the merger in 1981.

The pipe had some build-up on the bowl and the stem was heavily oxidized, but overall, it held a lot of promise for a restoration. Below is the pipe as received.

I used a piece of worn scotchbrite to remove the build-up on the bowl top. The bowl was reamed which revealed that the bowl interior was in very good condition. The bowl was soaked in alcohol and sea salt. I picked up an old Sugar dispenser for filling the bowl with salt, which worked very well (sealed with a piece of tape to keep the salt dry). While the bowl was soaking, the stem was soaked in some mild oxy-clean solution. I put a dab of grease on the C stem logo.

Following the soak, the shank was cleaned and stem inserted. I removed the oxidation with 400, 800, 1,000, 1,500 and 2,000 grade wet paper, followed by 8,000 micromesh. The stem was then polished with White Diamond and Meguiars plastic polish.

The bowl was buffed with White Diamond and several coats of Carnuba wax. Below is the finished pipe.