Blog by Henry Ramirez

In an earlier blog submission I created what I named a FrankenStem bit replacement on a chewed up Dunhill Shell bent. In heating the stem in the oven to straighten and re-bend it I inadvertently caused the stem/shank union to open (iatrogenic). I thought that if I could just sand down the high spot that everything would fit tight again. I wanted to be precise in my actions so I coated the tenon with a disclosing solution. I mated the pieces together and, quite frankly, am lucky I didn’t split the shank. The thickness of the powder was enough to cause quite a tight fit. It did show me where it was hanging up but I was terrified to push my luck.

I mated the pieces together and, quite frankly, am lucky I didn’t split the shank. The thickness of the powder was enough to cause quite a tight fit. It did show me where it was hanging up but I was terrified to push my luck.

Dunhill’s engineering and quality control are such that I knew everything should fit without additional removal of material. Upshallfan had mentioned his use of a heat gun to bend stems and I figured I’d try the same but on the tenon.

Dunhill’s engineering and quality control are such that I knew everything should fit without additional removal of material. Upshallfan had mentioned his use of a heat gun to bend stems and I figured I’d try the same but on the tenon. I heated the tenon until I could SMELL the vulcanite and then quickly inserted it into the shank and tweaked it with psi vs the shank’s mortise. After holding it for a minute, I removed it and ran it under cold water to set the shape.

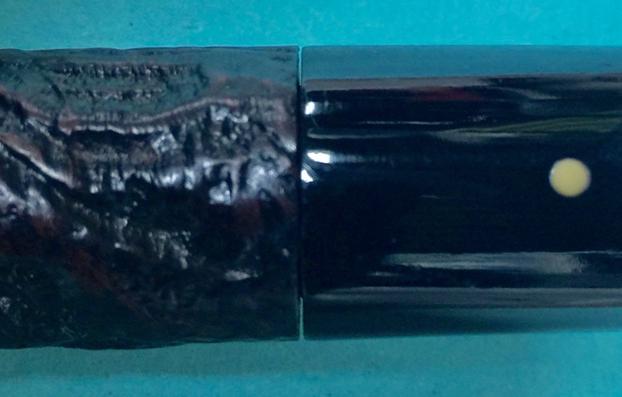

I heated the tenon until I could SMELL the vulcanite and then quickly inserted it into the shank and tweaked it with psi vs the shank’s mortise. After holding it for a minute, I removed it and ran it under cold water to set the shape. As you can see, even under magnification the fit is closed. It makes me wonder about other previously owned pipes that had this issue when I received them. I tried resurfacing the mortise and resurfacing the tenon with inadequate results. They were old pipe shop basket pipes so I don’t know if they ever fit together properly but I didn’t have that dilemma here. I was also pleased to note that my sense of smell is a powerful ally, not only when cooking but heating stems! Regards, Henry

As you can see, even under magnification the fit is closed. It makes me wonder about other previously owned pipes that had this issue when I received them. I tried resurfacing the mortise and resurfacing the tenon with inadequate results. They were old pipe shop basket pipes so I don’t know if they ever fit together properly but I didn’t have that dilemma here. I was also pleased to note that my sense of smell is a powerful ally, not only when cooking but heating stems! Regards, Henry