Blog by Steve Laug

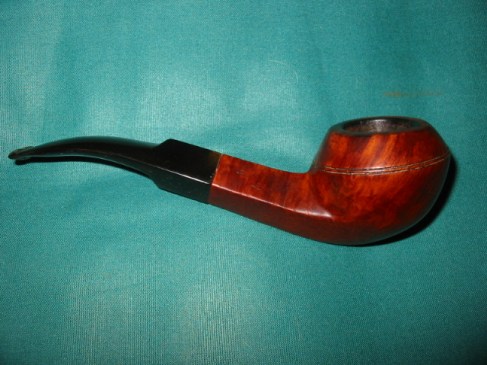

I picked up this little Savinelli Prince because I really like the shape of the pipe and the spigot style stem. I bid knowing full well that the stem had a bit through on it. Once it arrived I could have replaced the stem but decided to do a stem patch on it. The pipe itself was in great shape other than the bite through near the button on top of the stem. The underside of the stem was clean with no tooth marks or chatter. As I examined it I also noticed that the previous owner seemed to have done a halfway patch on it and in the process had broken a chunk out of the button and repaired with white glue. The white glue may have been applied by the seller to keep the pieces together while he sold it. I will never know for sure, but the glue would not hold for long as it is water soluble. The two pictures below show the extent of the damage in the stem and give a good idea of the state of the pipe as a whole. It was a great pipe with some unfortunate damage to the stem.

I cleaned off the broken chunk with a dental pick, which was surprisingly easy and makes my above assertion about the seller doing a quick patch up more likely. I cleaned off the debris on the chunk (it was not very big, but was an essential piece of the button). I washed it with Isopropyl alcohol. Then I re-glued it with clear super glue. I purposely over filled the crack and pushed the piece in place until it held. I would sand off the excess glue once I had dealt with the bite through on the stem.

The bite through was a mess as well. There was oxidation in the hole as well as some built up dust and dirt. I picked the hole clean with the dental pick (by now you know that this is one of my indispensable tools in the refurbishing process). I wiped it down with a cotton swab and Isopropyl alcohol to get a good clean hole. By this point it was black and clean. I used a small round needle file to clean up the rough edges on the hole as I wanted a solid surface to work with. I washed it yet again with the alcohol to remove the grit from filing.

This time, instead of using the greased pipe cleaner in the slot I used a small nail file that fit the slot perfectly and gave a base to the glue. The hole was too big for just a pipe cleaner to provide the coverage. I greased both surfaces of the file and inserted it in the slot in the button. I gradually built up the hole with repeated applications of super glue. I let the layers dry before adding a new coating of glue. I have found that if I build it slowly around the edges it gives a better repair. Once it was built up I over filled the hole to make sure it is well covered and the hole is no longer visible. On this particular pipe I used clear super glue because I was out of the black super glue. Both versions work exceptionally well but the black has the benefit of being the same colour as the stem and is a little less visible.

After the glue was dried I used the flat blade needle file to rework the button back into shape and give it the nice sharp edges that it should have. I sanded the stem smooth, removing the excess glue and the roughness of the glue. I went on to sand it with 400 and 600 wet dry sandpaper and a bit of water to remove the scratches left by the 240 grit paper. Then I used the full range of micromesh pads, 1500, 1800, 2400, 3200, 4000 and 6000 grit to smooth it out. As usual I had a bowl of water near at hand to dip the pads as I sanded and to wash them of the slurry that comes as I sanded. Once they were smooth and shiny, the last three grits of micromesh really do a nice job giving the stem a sheen, I took the pipe to my buffer I finished it with White Diamond polishing compound.

I have been asked in the past how long the stem patches hold up and the durability of the patch. I have no long term proof of their durability but I have had this pipe for about two years and have smoked it quite a bit and the patch shows no sign of giving way. I clean it as I would any other pipe with pipe cleaners after use and then periodically breaking it down to give it a thorough cleaning inside and out. I would say that is a pretty good track record for a patched pipe. Time will tell but in the meantime it is very smokeable and looks great in my opinion.