Blog by Greg Wolford

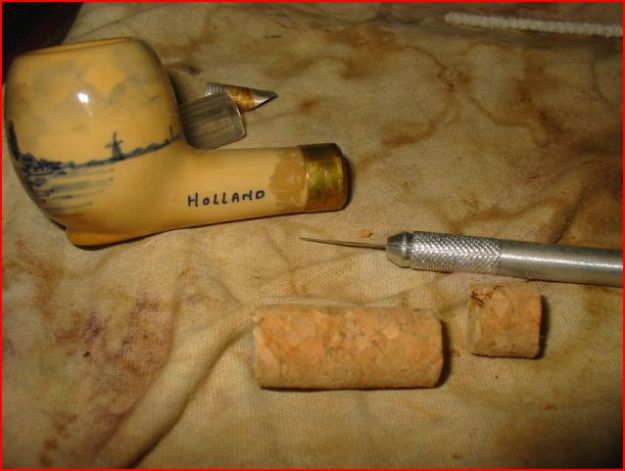

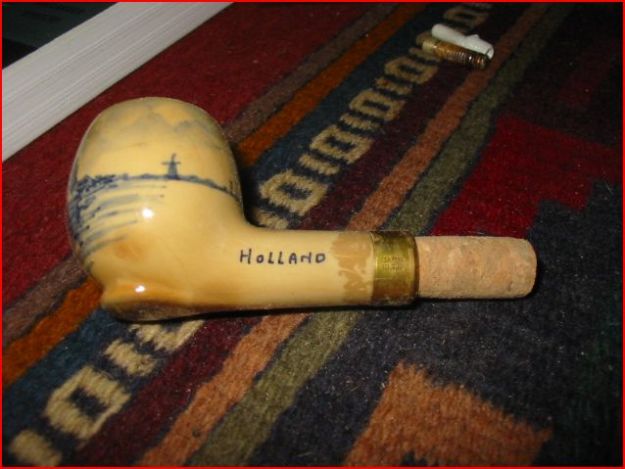

Several weeks ago I obtained a tenon turning tool from Pipe Maker’s Emporium (PME). I have been planning on writing my “review” of this tool since I mentioned it in the Big-Ben post but have put it off due to time and wanting to get better acquainted with the tool. Well, I think I am ready so here we go!

The tool can be purchased from PME here and is, essentially, the same tool that PIMO sells and Steve has and uses. There is at least two differences that I can see: An extra adjusting screw )which is rarely used) and the price of the PME tool is about $9 less. (Having bought from both sources, I have a personal preference for PME: their S/H costs are a bit less and speed and service are better, again in my opinion; I have no affiliation with either company other than being a customer.) Both tools are used in the same way and they both have similar limitations on size. They also both lack precision measurements/adjustment mark, requiring one to go slowly and check often the tenon size so as to not over-turn it.

Steve describes the use and adjustment very well in an article he wrote nut I can’t find at the moment. He also compared the PME and PIMO tools in this article so I won’t go into a lof ground he has already covered, but try to add my impression of the PME tool,

I found the tool relatively easy to use overall. I experimented on a few old stems before re-stemming Big-Ben and have since turned several other stems for different stummels and corn cob pipes. I have had mostly good results but there have been a few massive failures, too.

As Steve has pointed out, the best use of this tool is gotten by turning the tenon very close to size and then finishing the job by hand sanding. I have also learned that the tool not only has no markings to gauge the amount of material to be removed by a single adjustment (you have to look at the cutter head relative to the tenon) but one cannot gauge the amount consistently by using a “formula” such as 1/4 turn of the adjusting screw has been giving me .5′ decrease in diameter so each 1/4 turn will continue to do so – I have over-turned two stems using that type of “formula”!

PME doesn’t sell the right size drill bit for the guide pin (a size #30 or .128″) so you will have to obtain it from another source (PIMO does sell it for $2.50) or make due with another size. At first I used an 1/8″ bit on the vulcanite stems which, while tight, worked okay. However, I had to move up to a 5/32″ bit for Lucite/acrylic and be careful to not get it out of round. I have since ordered the .128″ bit from PIMO and am happy with that.

The extra set screw on the PME tool is really not used except for turning multiple tenons of the same style to the same size: For instance if you needed to slightly turn several tenons for corn cob pipes you would use it. This second locking screw just really sets the cutter head to zero movement but the main locking screw is the one that is generally used since you will mostly be taking more and more material off of a tenon.

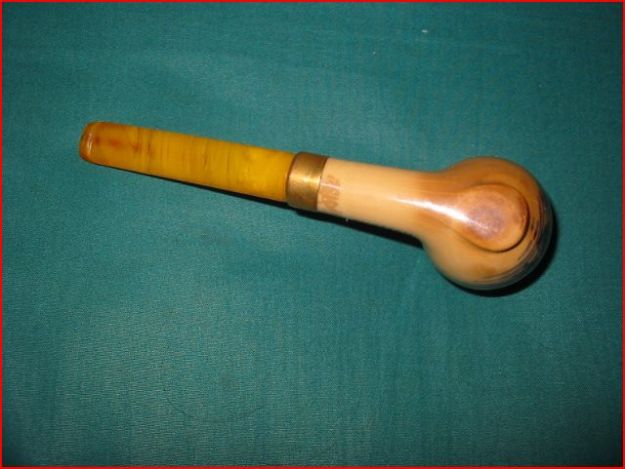

I find that using the tool at different speeds helps to get a nice, smooth tenon. I like to start out fairly slow and make my first pass, then increase the speed on subsequent passes. The final passes I will be at full speed and will slowly rotate the stem as I make the pass up then back down the tenon. Generally, this gives me a nice smooth tenon, without a lot of turning marks/lines.

As I mentioned above, the adjustments are not always equal so one has to watch carefully how much the cutter head advances with each movement of the adjusting screw. And in order to get a good, even result it is very important to lock the locking screw with each adjustment. I have found that my digital micrometer (bought very cheaply from Harbour Freight) is a good help in getting the size of the tenon down to where it needs to be. But due to the lack of real precision with the tool, I don’t think one can rely solely on the micrometer; when it is getting close I begin checking the tenon to mortise fit after every pass.

My analysis, then, would be something like this: If you wish to re-stem pipes you have to have one of these tools. I think that either the PME or PIMO tool would work as well as the other and which one you should purchase is simply a matter of preference or economics; the PME is cheaper but if you are ordering from one company or the other buying it with your order will save you on S/H costs. My personal recommendation would be (if you don’t already have some stems to experiment with) buy the tool from PME and order a dozen or two of whatever Carolyn has on sale that week to practice on (usually there are 2-3 styles of vulcanite stems on special for $4-$5) and maybe a couple of closeout acrylic ones, too, to get a feel for the difference (which is big!) in the two materials. The learning curve isn’t huge but it is there. But, if you are like me, learning a new skill to add to your arsenal of restoring these wonderful old pieces is a lot if fun and a big part of the draw of the hobby.

So what are you waiting for? Place your order and step into the next phase of the art of restoration.