by Steve Laug

The next pipe on the table is another one that came to us from the seller in Caldwell, Idaho, USA on 07/12/2025. The Bruyere finish, the shape and the Dunhill stamping caught our eye. It is stamped on the left side of the shank and reads P next to the bowl/shank union followed by Dunhill [over] Bruyere. On the right side it is stamped Made in [over] England15. That is followed by a circle 4A. It has a classic Bruyere smooth finish that is a stark contrast to vulcanite taper stem. The bowl appears to be moderately caked at first glance but could be thicker deeper in the bowl. The inner edge and the top show some lava overflow. The stem is oxidized and calcified which is quite normal for what I see. It also has some light tooth marks and chatter on the top and underside ahead of the button. The classic white spot is on the top of the stem and looks to be in good condition. I took some photos of the pipe to show the general condition of the pipe before I started his clean up.

I took photos of the bowl and rim top to show the thickness of the cake and the lava coat on the rim top. There was some tobacco debris in the bottom of the bowl. The stem photos show the condition of the stem ahead of the button.

I took photos of the bowl and rim top to show the thickness of the cake and the lava coat on the rim top. There was some tobacco debris in the bottom of the bowl. The stem photos show the condition of the stem ahead of the button. The stamping on the sides of the shank are clear and readable as noted above. I took a photo of the pipe with the stem removed to give a sense of the proportions of the pipe. It is a real beauty.

The stamping on the sides of the shank are clear and readable as noted above. I took a photo of the pipe with the stem removed to give a sense of the proportions of the pipe. It is a real beauty.

One of the first things I like to do is to unpack the stamping and understand each element in it. I turned to Pipephil’s helpful site (http://pipephil.eu/logos/en/dunhill/shell-briar1.html). The stamping is interpreted as follows: The P is the shape of the pipe which I assume is a Bulldog. The Dunhill Bruyere is the finish. Following the Made In England15 gives the year that the pipe was made. The circle 4A is the stamp for a Group 4 in a Bruyere finish.

One of the first things I like to do is to unpack the stamping and understand each element in it. I turned to Pipephil’s helpful site (http://pipephil.eu/logos/en/dunhill/shell-briar1.html). The stamping is interpreted as follows: The P is the shape of the pipe which I assume is a Bulldog. The Dunhill Bruyere is the finish. Following the Made In England15 gives the year that the pipe was made. The circle 4A is the stamp for a Group 4 in a Bruyere finish.

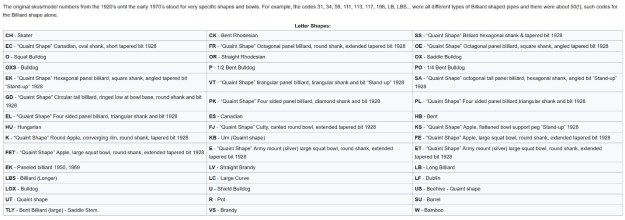

I turned to Pipedia’s shape charts on Dunhills (https://pipedia.org/wiki/Dunhill_Shape_Chart). I have included the shape charts from the site. The first is the chart as a whole and the second is a larger version of the right column.

From the above information I could see that I was working on a ½ Bent Bulldog shaped pipe. The chart shows that the P is the stamping for ½ Bent Bulldog. The pipe I have has a taper stem.

From the above information I could see that I was working on a ½ Bent Bulldog shaped pipe. The chart shows that the P is the stamping for ½ Bent Bulldog. The pipe I have has a taper stem.

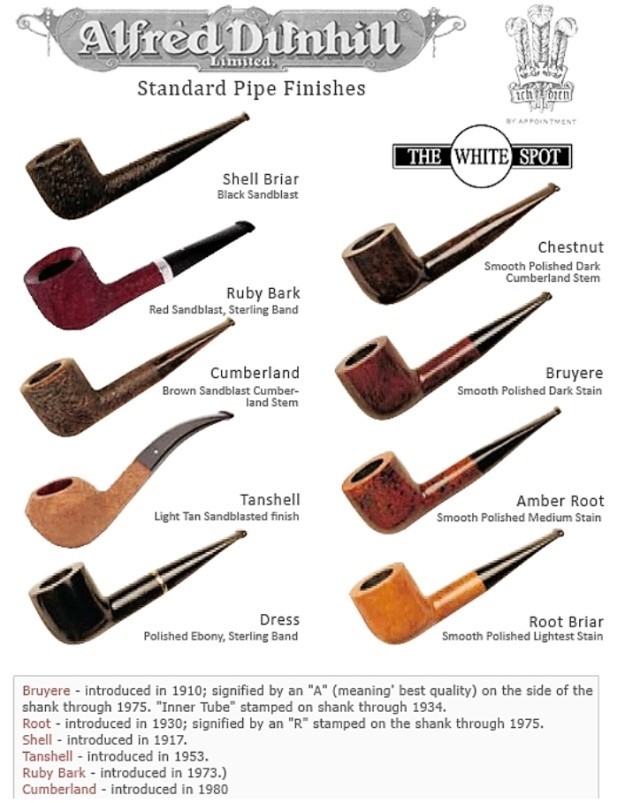

From there I turned to Pipedia’s section on Dunhill Bruyere Pipes to get a bit of background on the Dunhill finishes (https://pipedia.org/wiki/Dunhill#Root_Briar). I quote:

Bruyere

The original finish produced (usually made using Calabrian briar), and a big part of developing and marketing the brand. It was the only finish from 1910 until 1917. A dark reddish-brown stain. Before the 1950s, there were three possible finishes for Dunhill pipes. The Bruyere was a smooth finish with a deep red stain, obtained through two coats, a brown understain followed by a deep red.

There was a link on the above site to a section specifically written regarding the Bruyere finish (https://pipedia.org/wiki/Dunhill_Bruyere). I turned there and have included the information from that short article below.

Initially, made from over century-old briar burls, classified by a “B” (denoted highest quality pipe); “DR” (denoted straight-grained) and an “A” (denoted first quality), until early 1915. After that, they became a high-end subset to the Dunhill ‘Bruyere’. The DR and B pipes, a limited production, they should be distinguished as hand-cut in London from burls as opposed to the Bruyere line which was generally finished from French turned bowls until 1917, when the Calabrian briar started to be used, but not completely. Only in 1920 Dunhill took the final step in its pipe making operation and began sourcing and cutting all of its own bowls, proudly announcing thereafter that “no French briar was employed”.

Bruyere pipes were usually made using Calabrian briar, a very dense and hardy briar that has a modest grain but does very well with the deep red stain.

“Before the 1950s, there were three possible finishes for Dunhill pipes. The Bruyere was a smooth finish with a deep red stain, obtained through two coats, a brown understain followed by a deep red. The Shell finish was the original sandblast with a near-black stain (though the degree to which it is truly black has varied over the years). Lastly, the Root finish was smooth also but with a light brown finish. Early Dunhill used different briars with different stains, resulting in more distinct and identifiable creations… Over the years, to these traditional styles were added four new finishes: Cumberland, Dress, Chestnut and Amber Root, plus some now-defunct finishes, such as County, Russet and Red Bark.”

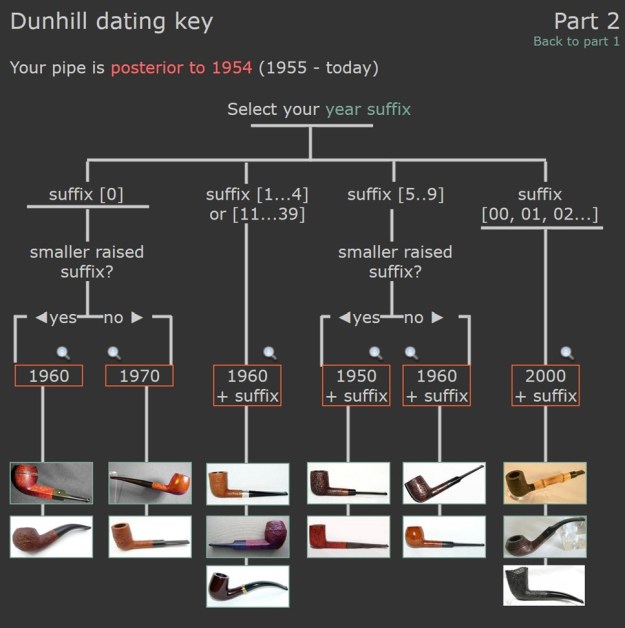

There was also a link to a catalogue page that gave examples and dates that the various finishes were introduced (https://pipedia.org/wiki/File:Dunnypipescatalog-1.png).  I turned to Pipephil’s dating guide to show how I arrived at the date of manufacture for this pipe (http://www.pipephil.eu/logos/en/dunhill/cledat-en1a.html). I am including the chart that is provided there for the dating a pipe. I have drawn a red box around the section. Since the pipe I am working on has a suffix15 that is raised. It to the 1960 line on the chart below. It also gave me the formula for dating the pipe – 1960 + suffix 15 = 1975.

I turned to Pipephil’s dating guide to show how I arrived at the date of manufacture for this pipe (http://www.pipephil.eu/logos/en/dunhill/cledat-en1a.html). I am including the chart that is provided there for the dating a pipe. I have drawn a red box around the section. Since the pipe I am working on has a suffix15 that is raised. It to the 1960 line on the chart below. It also gave me the formula for dating the pipe – 1960 + suffix 15 = 1975. I now knew that I was working on a Bruyere that came out in 1975. The shape of the pipe was ½ Bent Bulldog that Dunhill put out and that the P was a normal shape designation.

I now knew that I was working on a Bruyere that came out in 1975. The shape of the pipe was ½ Bent Bulldog that Dunhill put out and that the P was a normal shape designation.

Armed with that information I turned to work on the pipe itself. I reamed the bowl with a PipNet pipe reamer using the cutting heads 2 and 3. I finished the reaming with a Savinelli Fitsall Pipe Knife. I sanded the walls of the bowl with 220 grit sandpaper wrapped around a piece of dowel.

I scraped the rim top with the Fitsall Pipe Knife to remove as much of the lava coat as I could. I followed that up with a 320 and 400 grit sanding pad. It was beginning to look much better.

I scraped the rim top with the Fitsall Pipe Knife to remove as much of the lava coat as I could. I followed that up with a 320 and 400 grit sanding pad. It was beginning to look much better. I cleaned out the inside of the shank and the airway in the stem with alcohol, cotton swabs and both bristle and regular pipe cleaners.

I cleaned out the inside of the shank and the airway in the stem with alcohol, cotton swabs and both bristle and regular pipe cleaners.  I scrubbed the bowl and shank with a tooth brush and some undiluted Murphy’s Oil Soap. I rinsed it off with warm water to remove the dust and soap from the finish. I dried it off with a soft cloth and it looked much better.

I scrubbed the bowl and shank with a tooth brush and some undiluted Murphy’s Oil Soap. I rinsed it off with warm water to remove the dust and soap from the finish. I dried it off with a soft cloth and it looked much better.

I sanded the bowl with 320-3500 grit 2×2 inch pads. I wiped the bowl down with a damp cloth after each sanding pad.

I sanded the bowl with 320-3500 grit 2×2 inch pads. I wiped the bowl down with a damp cloth after each sanding pad.

I polished the briar with 1500-12000 grit micromesh sanding pads to develop the shine. It began to look very good. It had a rich shine in the finish.

I polished the briar with 1500-12000 grit micromesh sanding pads to develop the shine. It began to look very good. It had a rich shine in the finish.

The exterior of the bowl look better after sanding. I worked some Before & After Restoration Balm into the briar with my finger tips. I let it sit for 10 minutes and then buffed it off with a soft cloth. The product is a great addition to the restoration work. It enlivens, enriches and protects the briar while giving it a deep glow. It is a product I use on every pipe I restore.

The exterior of the bowl look better after sanding. I worked some Before & After Restoration Balm into the briar with my finger tips. I let it sit for 10 minutes and then buffed it off with a soft cloth. The product is a great addition to the restoration work. It enlivens, enriches and protects the briar while giving it a deep glow. It is a product I use on every pipe I restore.

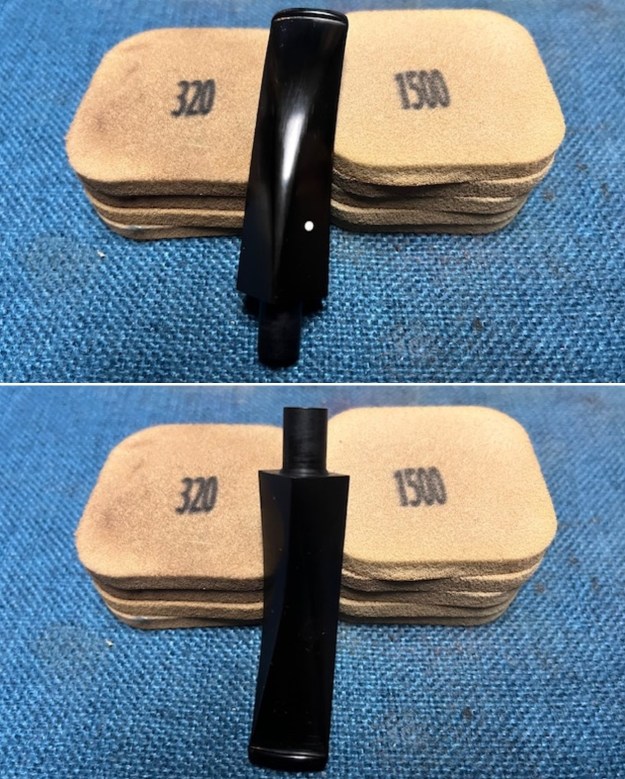

I set the bowl aside and worked on the stem. I sanded the surface of the stem with a folded piece of 220 grit sandpaper to remove the oxidation and clean up the tooth marks and chatter on both sides of the stem ahead of the button.

I set the bowl aside and worked on the stem. I sanded the surface of the stem with a folded piece of 220 grit sandpaper to remove the oxidation and clean up the tooth marks and chatter on both sides of the stem ahead of the button.  I sanded the stem with 320-3500 grit 2×2 inch pads. I wiped the stem down with an Obsidian Oil cloth after each sanding pad.

I sanded the stem with 320-3500 grit 2×2 inch pads. I wiped the stem down with an Obsidian Oil cloth after each sanding pad. It was ready for the next step. I polished it with micromesh sanding pads – dry sanding with 1500-12000 grit pads and wiping the surface down with Obsidian Oil after each sanding pad. It is really shining. I polished it further with Before & After Stem Polish – both Fine and Extra Fine. I gave it another coat of Obsidian Oil to finish this step.

It was ready for the next step. I polished it with micromesh sanding pads – dry sanding with 1500-12000 grit pads and wiping the surface down with Obsidian Oil after each sanding pad. It is really shining. I polished it further with Before & After Stem Polish – both Fine and Extra Fine. I gave it another coat of Obsidian Oil to finish this step.

This 1975 Dunhill Bruyere P ½ Bent Bulldog Group 4A is a beautiful looking piece of briar that has a shape that follows grain. It is a great looking pipe that came out looking even better after the cleanup. The Bruyere is an early finish that Dunhill specialized in making. The finish on the pipe is in excellent condition. The red and brown stain on the bowl works well to highlight the grain. The polished black vulcanite taper stem adds to the mix. With the grime gone from the finish and the bowl it was a beauty and is eye-catching. I put the stem back on the bowl and buffed the pipe with Blue Diamond on the buffing wheel being careful to not buff the stamping. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing it with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished 1975 Dunhill Bruyere P ½ Bent Bulldog is quite nice and feels great in the hand. Give the finished pipe a look in the photos below. I can only tell you that like the other pipes I am working that it is much prettier in person than the photos capture. The dimensions of the pipe are Length: 5 inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 37 grams/1.34 ounces. It will soon be added to the British Pipe Makers Section on the rebornpipes store.

This 1975 Dunhill Bruyere P ½ Bent Bulldog Group 4A is a beautiful looking piece of briar that has a shape that follows grain. It is a great looking pipe that came out looking even better after the cleanup. The Bruyere is an early finish that Dunhill specialized in making. The finish on the pipe is in excellent condition. The red and brown stain on the bowl works well to highlight the grain. The polished black vulcanite taper stem adds to the mix. With the grime gone from the finish and the bowl it was a beauty and is eye-catching. I put the stem back on the bowl and buffed the pipe with Blue Diamond on the buffing wheel being careful to not buff the stamping. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing it with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished 1975 Dunhill Bruyere P ½ Bent Bulldog is quite nice and feels great in the hand. Give the finished pipe a look in the photos below. I can only tell you that like the other pipes I am working that it is much prettier in person than the photos capture. The dimensions of the pipe are Length: 5 inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 37 grams/1.34 ounces. It will soon be added to the British Pipe Makers Section on the rebornpipes store.

As always, I encourage your questions and comments as you read the blog. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipe men and women who hold our pipes in trust until they pass on into the trust of those who follow us.