By Al Jones

This rusticated billiard caught my eye on eBay recently, as I do no see many (any) swan neck pipes, save the very rare Dunhill LC. This one was stamped BG and made in France. I didn’t find any information about the BG brand, but “Who Made That Pipe” says it was made by the Delacour Compay.

Update 12/13/2025:

From a comment below by Kenneth Leiblich he shared the correct manufacturer:

Hey Al, you may be interested to know that this pipe is, in fact, made by Berrod-Regad of France. The original company dates back to 1875, but the current company is more of conglomerate (they own Butz-Choquin, Chap, Claude Romain, Bontemps, Dr. Boston, and Jima). Here is a link to Pipephil which shows the same logo as yours.

I knew from previous Delcour pipes that Steve and I had restored, that the Delcour factory was located in St. Claude France (not surprisingly!) The factory was dissolved by 1955, so I assume this pipe was made before that year.

The pipe looked to be in excellent condition, save for a heavily oxidized stem. It looked large in the eBay ad photos, but I was surprised to find it to be relatively diminutive at 28 grams. Below is the pipe as it was received.

I can’t quite make out the stamping on the nomenclature, something GRAIN? And what looks to be the IAR from BRIAR.

I was curious as to how a pipe with such a slender, curved shank could be drilled. I found a thread on the PipesMagazine forum with comments from Jesse Silver (Barlings & other expert) and former pipe maker Zack Hamric.

From Jesse Silver:

Nothing new about curved drilling. French carvers were using it early in the last century, Genod being one of them, which allowed them to create bents with delicate shank profiles. The famous Dunhill 120 swan’s neck is based off of the Genod design, but Dunhill didn’t have the knowledge to drill curved airways as the French weren’t sharing. So, some of these Dunhills have shanks that were spliced to the bowl to allow for straight drilling in sections.

From Zack Hamrick:

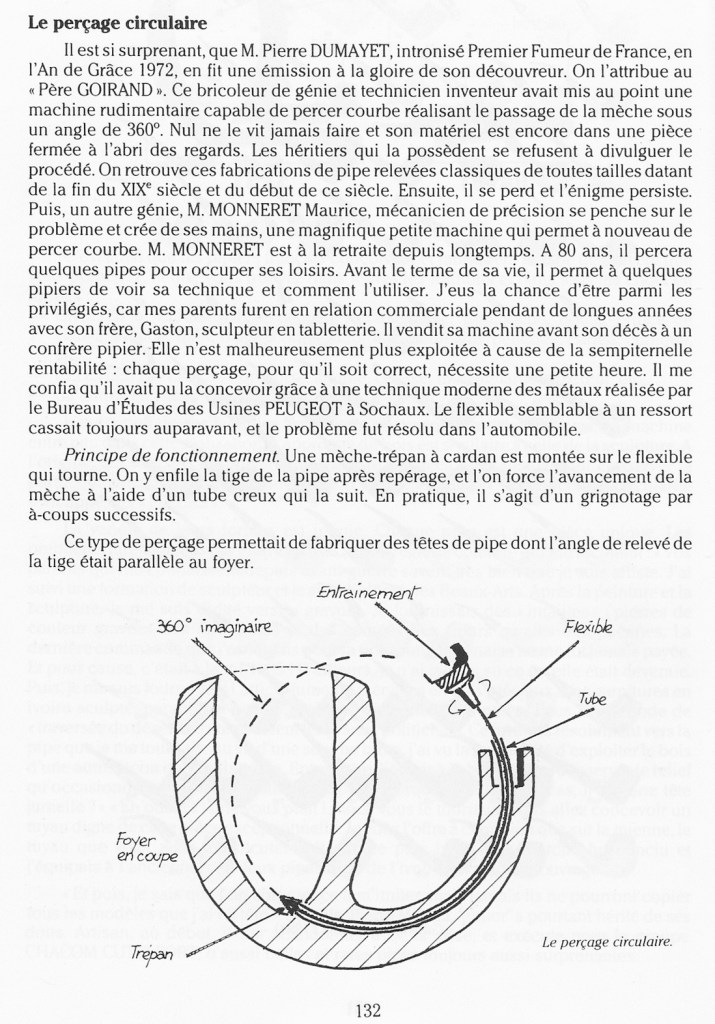

Guys, here’s a link to the method- Curved pipe drilling

It involves a flexible shaft with a burr soldered to the end.That fits inside a curved tube You hold the stummel in a vise, drill a starter hole and start feeding the tube and spinning cutter into the block. There’s no chip clearance, so you have to back it out every .25″ or so…and it takes a long time…

The worse part about this is that you can’t get a reamer through the curved channel, the draft hole has to be oversize to begin with to accommodate the tube and cutter, and the inner surface would be much rougher than a conventional draft hole…

Other than that, it’s a fine idea- there’s a reason almost nobody uses this technique….

Zacks link went to this photo showing the drilling process, with an explanation in French.

There was almost no cake in the bowl, which is conical shaped. I used a piece of 320 sandpaper wrapped around my smallest reamer bit to get the bowl perfectly clean. Cleaning the draft hole was challenging. My straight bit would not go thru. I used a very small diameter bristle brush, bent slightly and dipped in alcohol and slowly got thru the shank and into the bowl. I soaked the bowl with isopropyl alcohol and sea salt, then carefully scrubbed the shank with a brush dipped in alcohol. The shank is quite thin and delicate, so care was needed.

During the soak, I put a dab of white acrylic nail polish on the stamped BG stem logo.

I used a Scotch-Brite pad to remove the layer of nail polish, down to the stamped initials. I used 600, 800, 1,500 and 2,000 grit sandpaper to remove the oxidation. A magic eraser was used around the stamp. The pipe was then buffed with White Diamond and Meguiars Plastic polish. The briar was buffed by hand with Halycon wax.

Below is the finished pipe.